A high-performance final output system for high-power RF sources

An output system and radio frequency output technology, applied in the field of radio frequency sources, can solve problems such as poor performance, increased heat dissipation, increased cost, etc., and achieve the effects of avoiding the use of PCB, reducing operating temperature, and small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

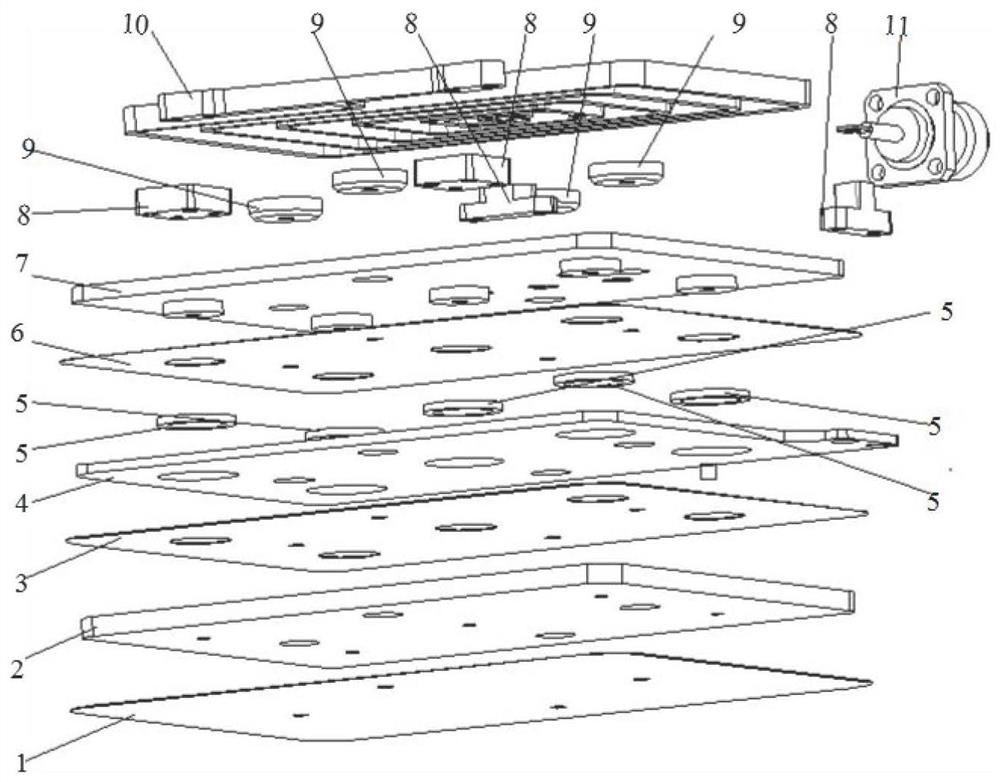

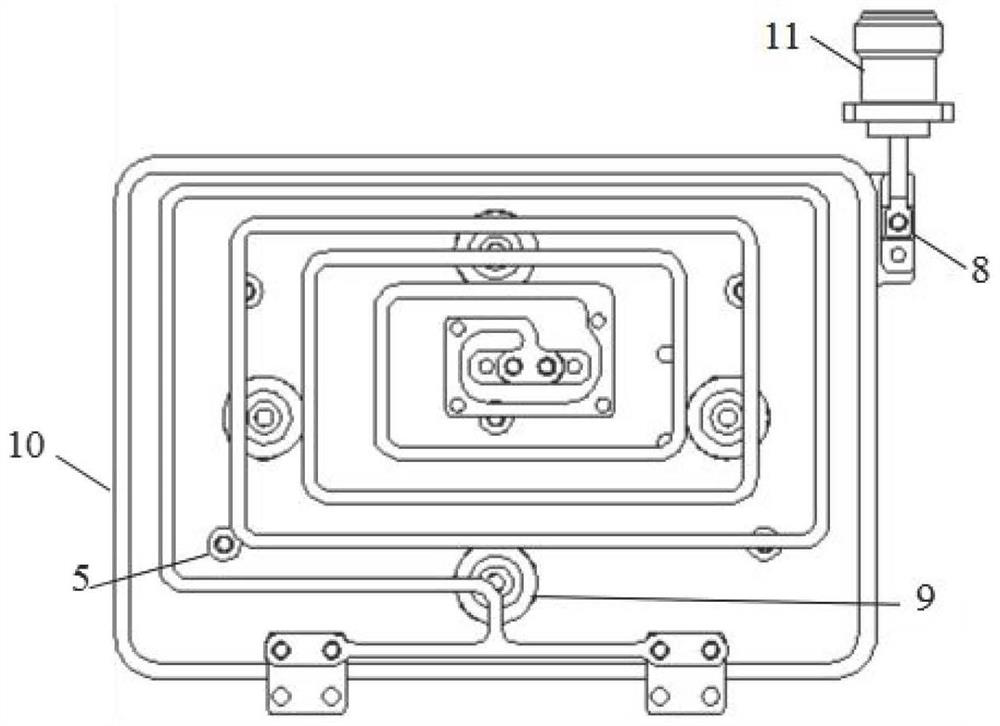

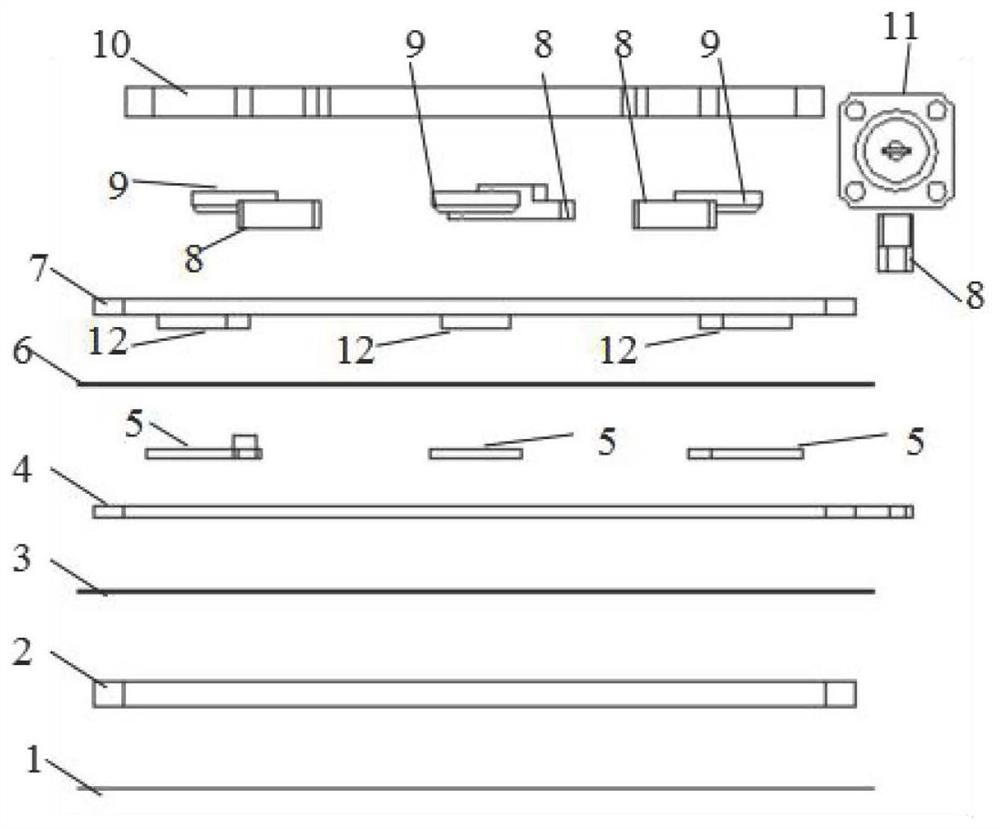

[0036]A high-performance final output system for a high-power radio frequency source, including: a cavity, an inductor and a capacitor arranged in the cavity, and the capacitor includes a first capacitor and a second capacitor; one end of the inductor is externally connected to the power of the high-power radio frequency source amplifier, the other end of the inductance is connected to the first capacitor and one end of the second capacitor respectively, the other end of the first capacitor is the radio frequency output end, and the other end of the second capacitor is grounded, such as Figure 1 ~ Figure 3 As shown, both the first capacitor and the second capacitor are plate capacitors (consisting of the capacitor bottom plate 2, the second capacitor top plate 4 and the first capacitor top plate 7), and the inductor 10 is a planar spiral metal strip. Wherein, the plate corresponding to the other end of the second capacitor is the cavity bottom plate of the cavity, and the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com