Bamboo breaking knife

A technology of bamboo knives and knife holders, which is applied to wood splitting devices, wood processing equipment, manufacturing tools, etc., can solve the problems of low cutting efficiency, easy wear of knives, and increased costs, so as to save the cost of knives and reduce the probability of breakage. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

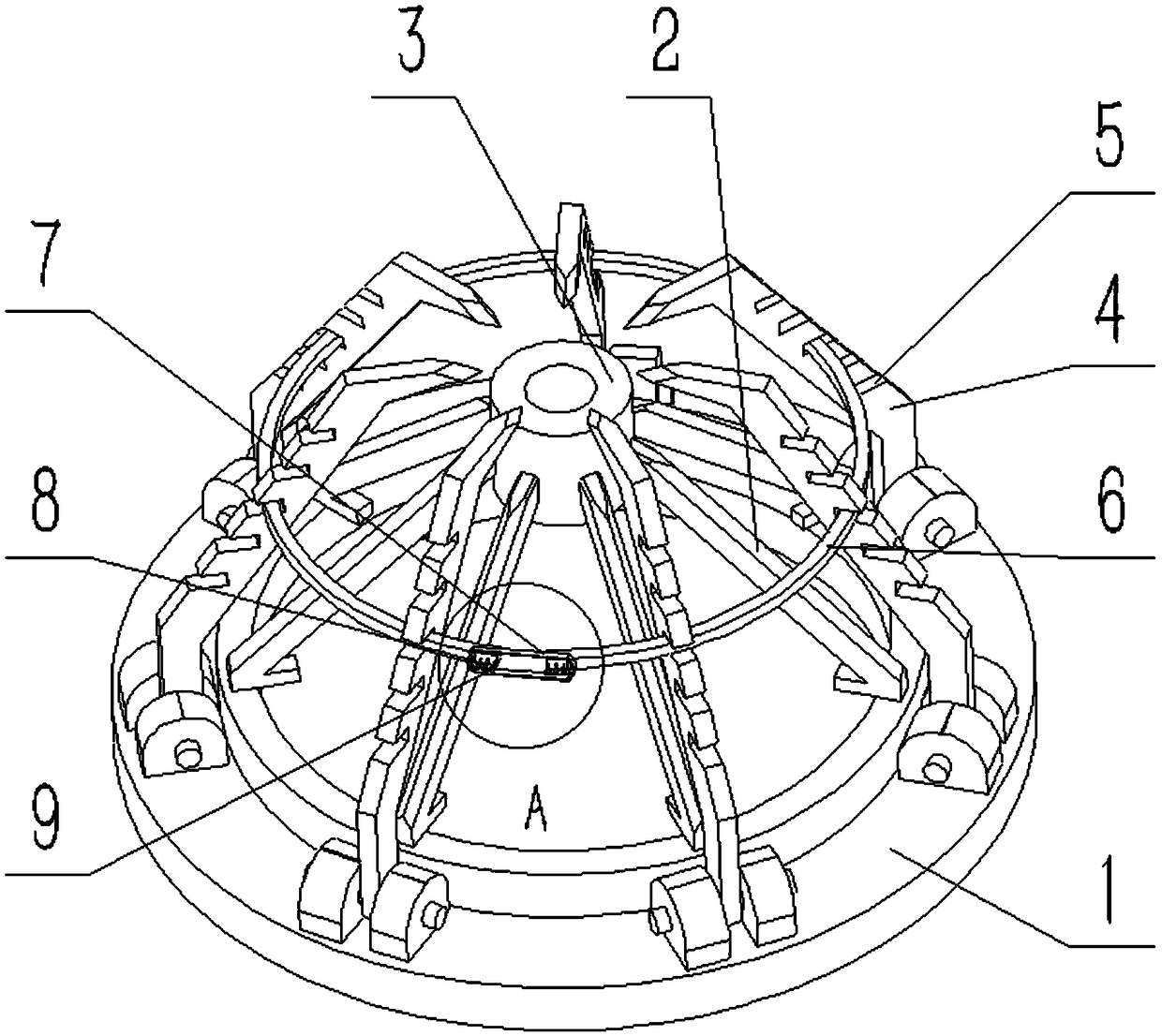

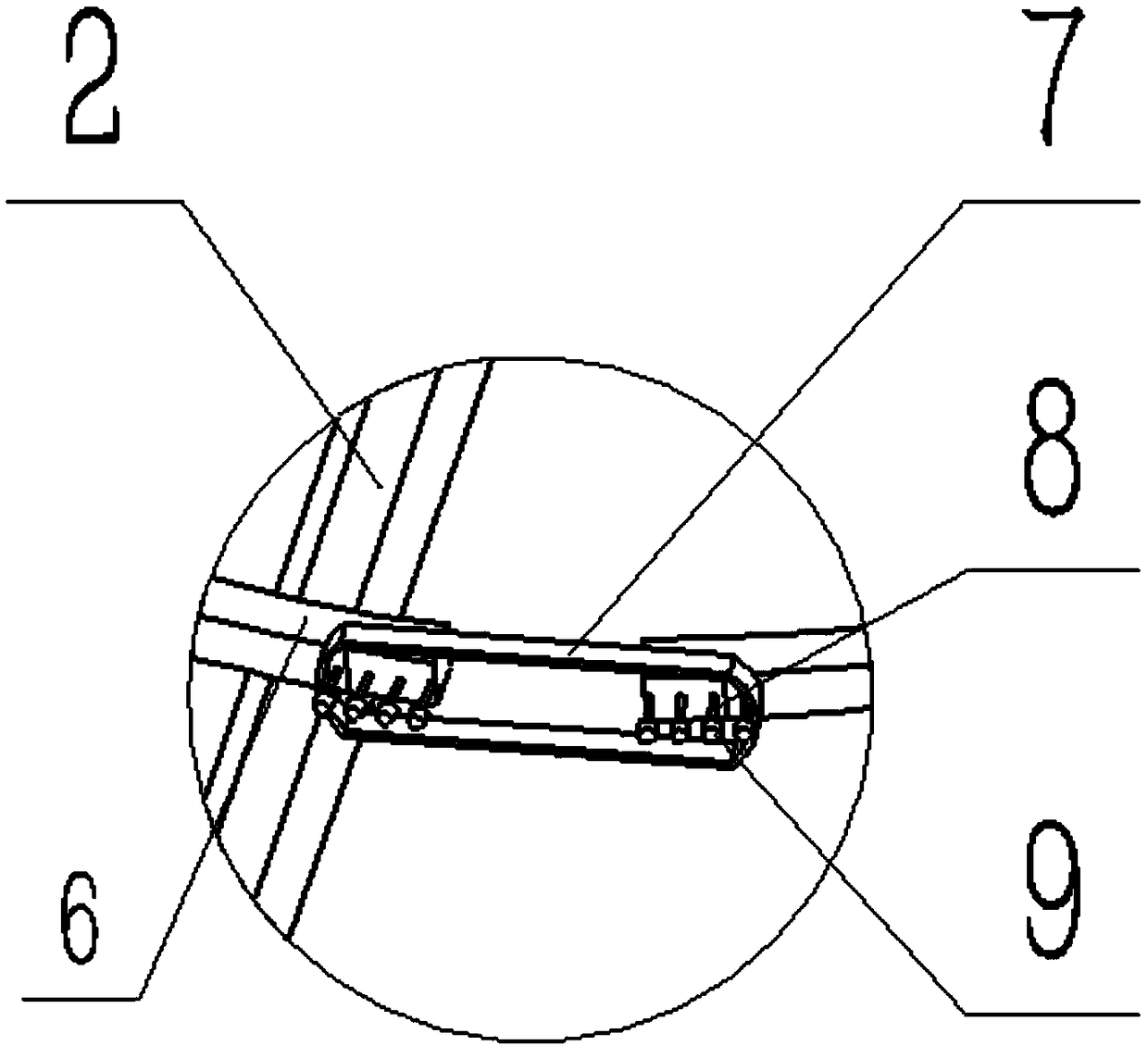

[0017] combined with figure 1 And attached figure 2 A kind of broken bamboo knife of the present invention is described further.

[0018] As shown in the accompanying drawing, it is a kind of broken bamboo knife, which includes a knife seat 1, a main blade 2, and a centering shaft 3. The central axis of the centering shaft 3 is evenly fixed with a plurality of main blades 2, one end of the main blade 2 is fixed to the tool seat 1, and the other end is fixed to the centering shaft 3, and a plurality of auxiliary blades 4 are evenly arranged on the outer edge of the tool seat 1 , the quantity of auxiliary blade 4 is consistent with main blade 2, and auxiliary blade 4 is positioned in same plane with main blade 2, and auxiliary blade 4 can cut into a part of bamboo earlier like this, allows main blade 2 to cut bamboo more conveniently, thereby reduces main The probability of blade 2 breaking makes the main blade 2 last longer. The bottom of the auxiliary blade 4 is hinged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com