Blended type garlic essence and preparation method thereof

A technology of garlic essence and essence, which is applied in the direction of food ingredients as odor improvers, food ingredients containing natural extracts, food drying, etc., which can solve the problems of unstable quality of fresh garlic, easy caking flavor of products, easy oxidation and change of taste, etc. , to achieve the effects of solubility, no agglomeration, stable product flavor, and easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

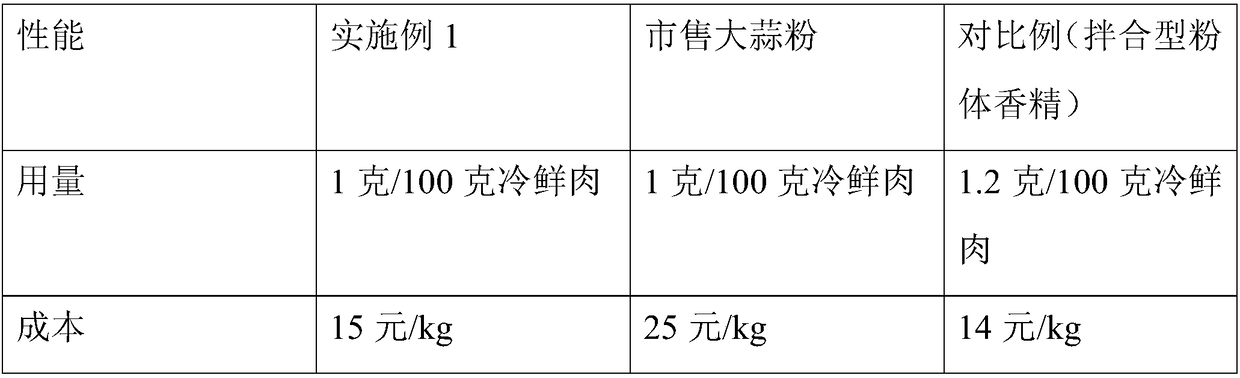

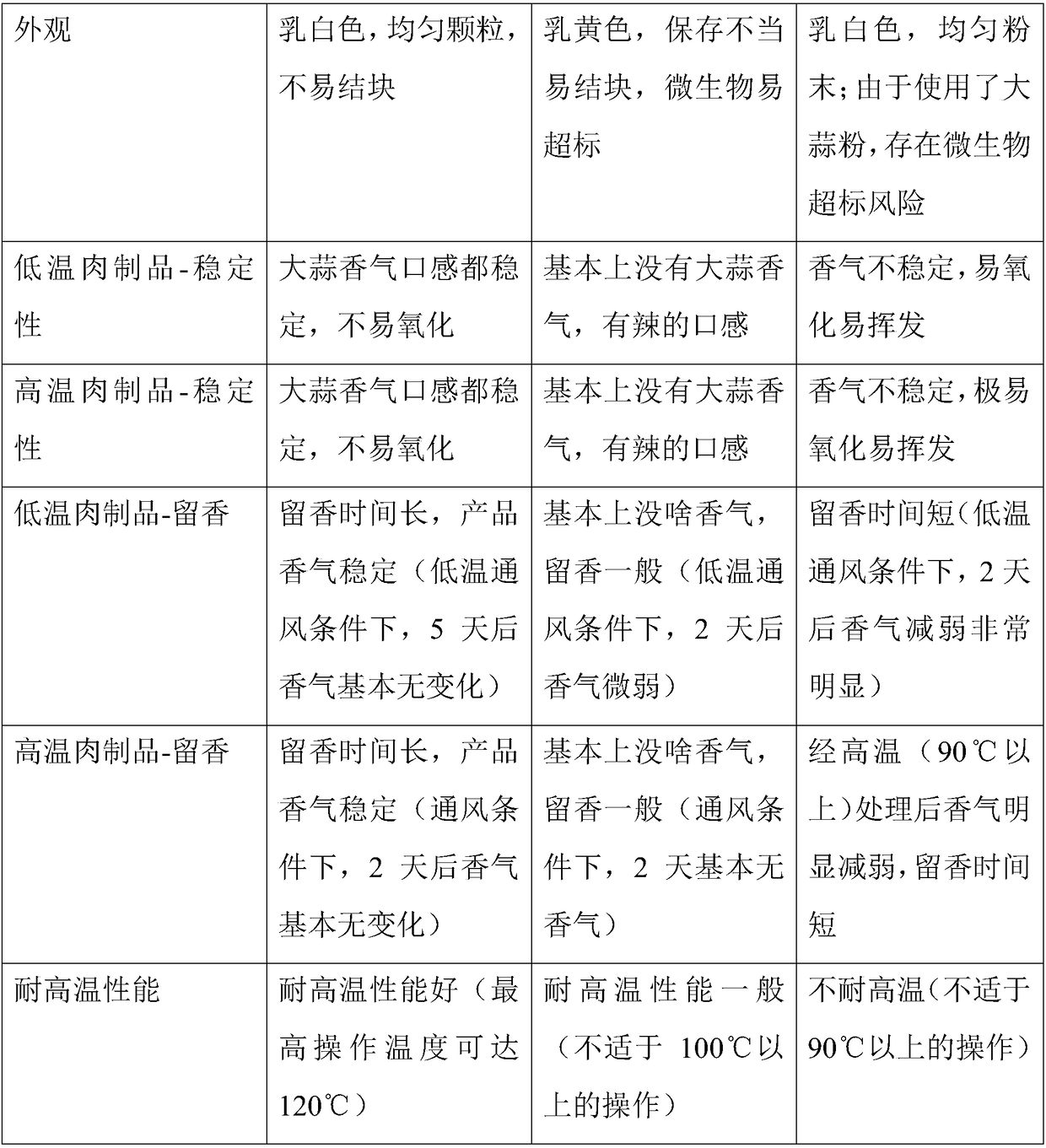

Examples

Embodiment 1

[0018] Capsule type garlic essence: 7 parts by weight of garlic oil, 5 parts by weight of garlic oleoresin, 0.1 part by weight of ginger essential oil, 15 parts by weight of maltodextrin, 15 parts by weight of gum arabic, 8 parts by weight of sodium starch octenyl succinate and 2 parts by weight of Quillaja bark extract, the rest is deionized water, and the solid content is controlled at 40-45%.

[0019] Mixing type garlic essence: 10 parts by weight of capsule type garlic essence, 32 parts by weight of maltodextrin, 4 parts by weight of salt powder, 3 parts by weight of ginger powder, 5 parts by weight of onion powder, 4 parts by weight of hydrolyzed plant Protein powder, 20 parts by weight of cornstarch and 2 parts by weight of deionized water.

[0020] Preparation:

[0021] a. After heating the deionized water to 45°C, add maltodextrin, soap bark extract, sodium starch octenyl succinate and gum arabic, and stir for 20 minutes to obtain a uniform milky yellow liquid;

[00...

Embodiment 2

[0027] Capsule type garlic essence: 12 parts by weight of garlic oil, 6 parts by weight of garlic oleoresin, 0.2 parts by weight of ginger essential oil, 10 parts by weight of maltodextrin, 20 parts by weight of gum arabic, 9 parts by weight of octenyl succinic acid starch Sodium and 4 parts by weight of soap tree bark extract, the rest is deionized water, and the solid content is controlled at 45-50%.

[0028] Stirring type garlic essence: 12 parts by weight of capsule type garlic essence, 2 parts by weight of deionized water, 40 parts by weight of maltodextrin, 3 parts by weight of salt powder, 20 parts by weight of cornstarch, 6 parts by weight of hydrolyzed plant Protein powder, 3 parts by weight of ginger powder and 10 parts by weight of onion powder.

[0029] Preparation:

[0030] a. After heating the deionized water to 45°C, add maltodextrin, soap bark extract, sodium starch octenyl succinate and gum arabic, and stir for 30 minutes to obtain a uniform milky yellow liqu...

Embodiment 3

[0036] Capsule type garlic essence: 8 parts by weight of garlic oil, 8 parts by weight of garlic oleoresin, 0.2 parts by weight of ginger essential oil, 2 parts by weight of Quillaja bark extract, 10 parts by weight of maltodextrin, 12 parts by weight of Arabica Glue and 12 parts by weight of starch sodium octenyl succinate, the rest is deionized water, and the solid content is controlled at 43%.

[0037] Mixing type garlic essence: 13 parts by weight of capsule type garlic essence, 40 parts by weight of maltodextrin, 3 parts by weight of salt powder, 2 parts by weight of ginger powder, 12 parts by weight of onion powder, 6 parts by weight of hydrolyzed plants Protein powder, 27 parts by weight of cornstarch and 1.6 parts by weight of deionized water.

[0038] Preparation:

[0039] a. After heating the deionized water to 48°C, add maltodextrin, soap bark extract, sodium starch octenyl succinate and gum arabic, and stir for 30 minutes to obtain a uniform milky yellow liquid; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com