A single-point incremental forming processing device for tubular parts

A single-point incremental, forming processing technology, applied in the field of single-point incremental forming, can solve the problems of long manufacturing cycle and high cost, and achieve the effects of fast production speed, high production efficiency, and improved one-time success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

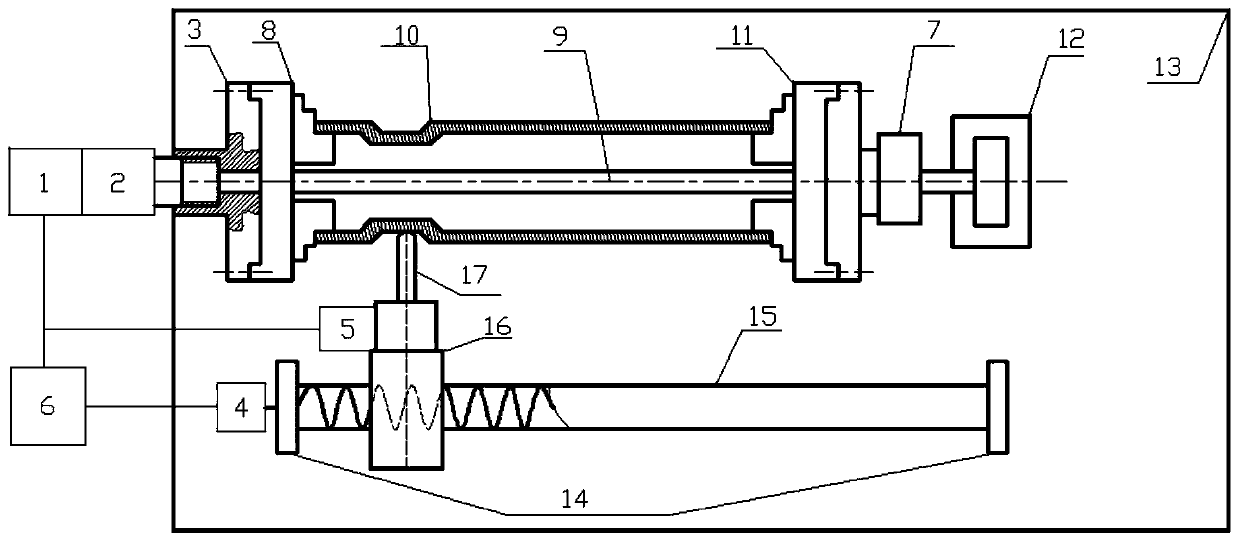

[0017] combine figure 1 , a single-point incremental forming processing device for tubular parts of the present invention, including a clamping and rotating mechanism for realizing the rotation of the tubular part, a feed mechanism for realizing the movement of the forming tool head, and control for controlling the rotation of the clamping and rotating mechanism and the movement of the tool head device 6;

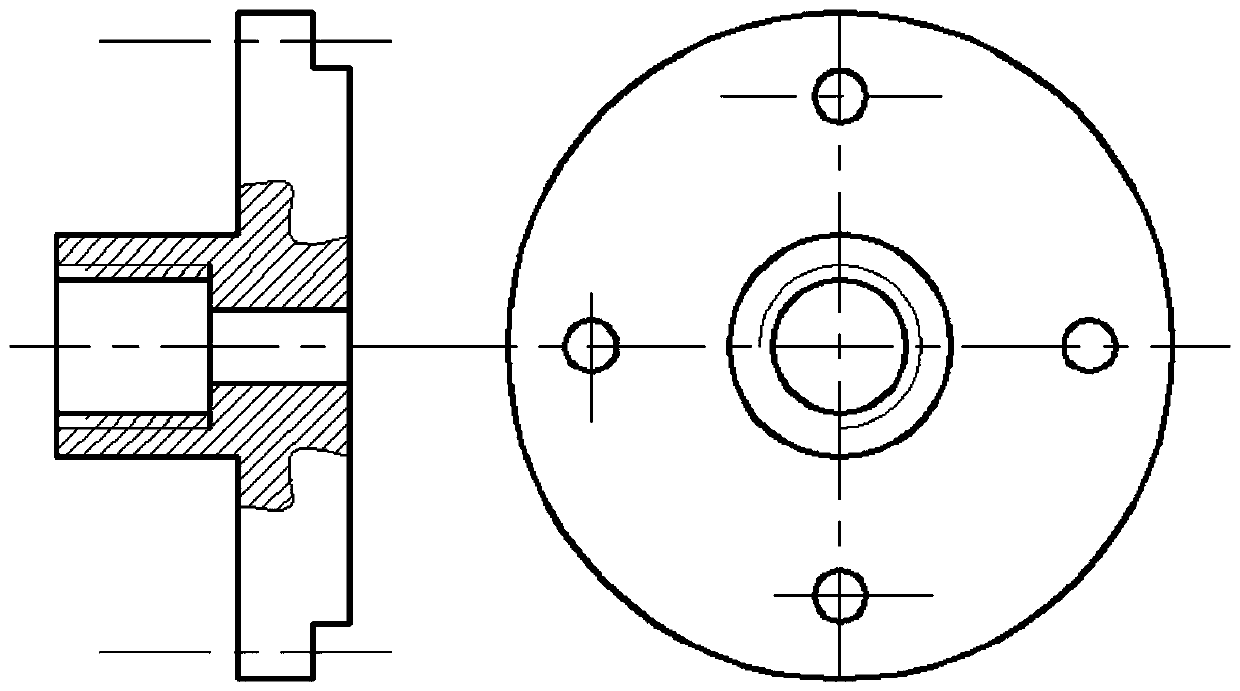

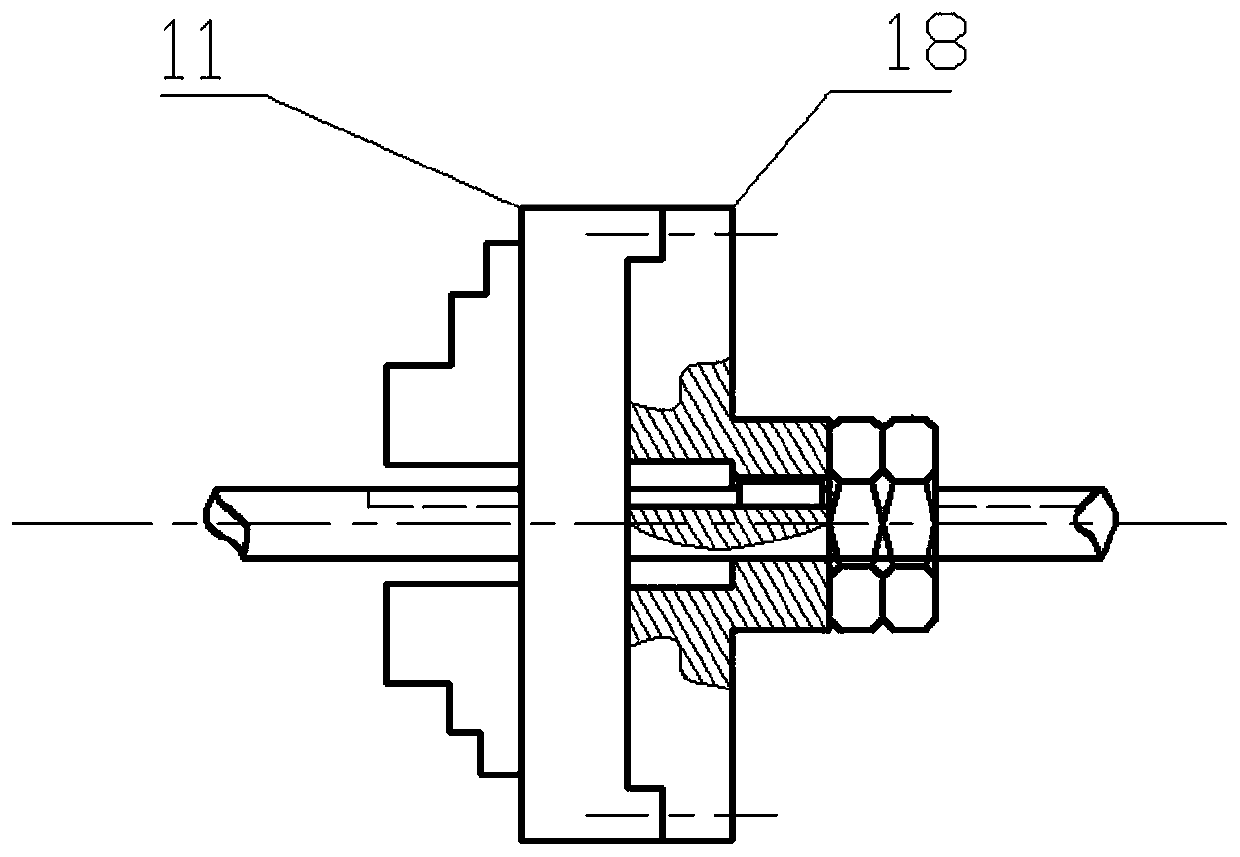

[0018] The clamping and rotating mechanism includes a first stepping motor 1, a reducer 2, a first connecting member 3, an axial locking mechanism 7, a first three-grip chuck 8, a second three-grip chuck 11, a transmission shaft 9 and support frame 13;

[0019] The first stepper motor 1 is connected to the reducer 2, and the reducer 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com