Foam glass used for continuous furnace thermal insulation layer, and preparation method thereof

A foam glass and insulation layer technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as uneven foaming, affecting the strength of foam glass, reducing the strength and thermal conductivity of foam glass, and achieving various The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

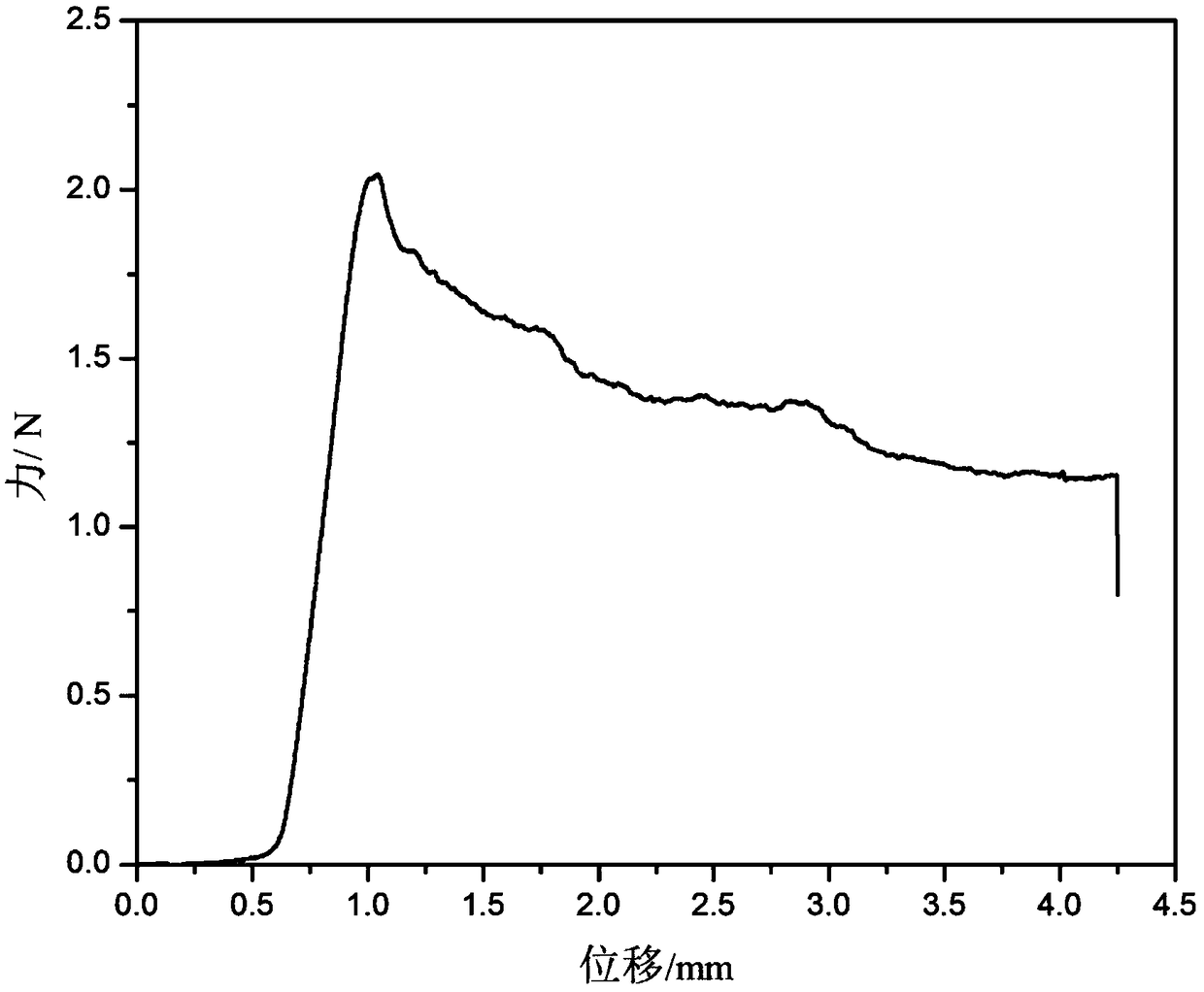

Examples

Embodiment 1

[0025] A kind of foam glass for continuous furnace insulation layer, its preparation method is:

[0026] Step 1, sending waste glass as raw material, foaming agent calcium carbonate, fluxing agent sodium fluorosilicate, and stabilizing agent sodium phosphate into a ball mill for ball milling, and the particle fineness after ball milling is 150 mesh to obtain a mixture. Among them, the waste glass is flat glass powder, made of SiO 2 、Al 2 o 3 , CaO, MgO, Na 2 O, K 2 O composition, and SiO 2 、Al 2 o 3 , CaO, MgO, Na 2 O, K 2 The weight content of O is 75%, 2.5%, 3%, 4.5%, 10%, 5% respectively; the mass percentages of calcium carbonate, sodium fluorosilicate and sodium phosphate are 1%, 6%, 7%, respectively.

[0027] Step 2, put the ground mixture into a high temperature resistant mold, preheat at 450°C for 25 minutes, then raise the temperature to 850°C for foaming, and keep it warm for 40 minutes, then cool down to 530°C for annealing, keep it warm for 60 minutes, and ...

Embodiment 2

[0030] A kind of foam glass for continuous furnace insulation layer, its preparation method is:

[0031] Step 1, sending waste glass as raw material, foaming agent calcium carbonate, fluxing agent sodium fluorosilicate, and stabilizing agent sodium phosphate into a ball mill for ball milling, and the particle fineness after ball milling is 150 mesh to obtain a mixture. Among them, the waste glass is flat glass powder, made of SiO 2 、Al 2 o 3 , CaO, MgO, Na 2 O, K 2 O composition, and SiO 2 、Al 2 o 3 , CaO, MgO, Na 2 O, K 2 The weight content of O is 75%, 2.5%, 3%, 4.5%, 10%, 5% respectively; the mass percentages of calcium carbonate, sodium fluorosilicate and sodium phosphate are 0.8%, 6%, 7%, respectively.

[0032] Step 2, put the ground mixture into a high temperature resistant mold, preheat at 450°C for 30 minutes, then raise the temperature to 860°C for foaming, and keep it warm for 45 minutes, then cool down to 500°C for annealing, keep it warm for 50 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com