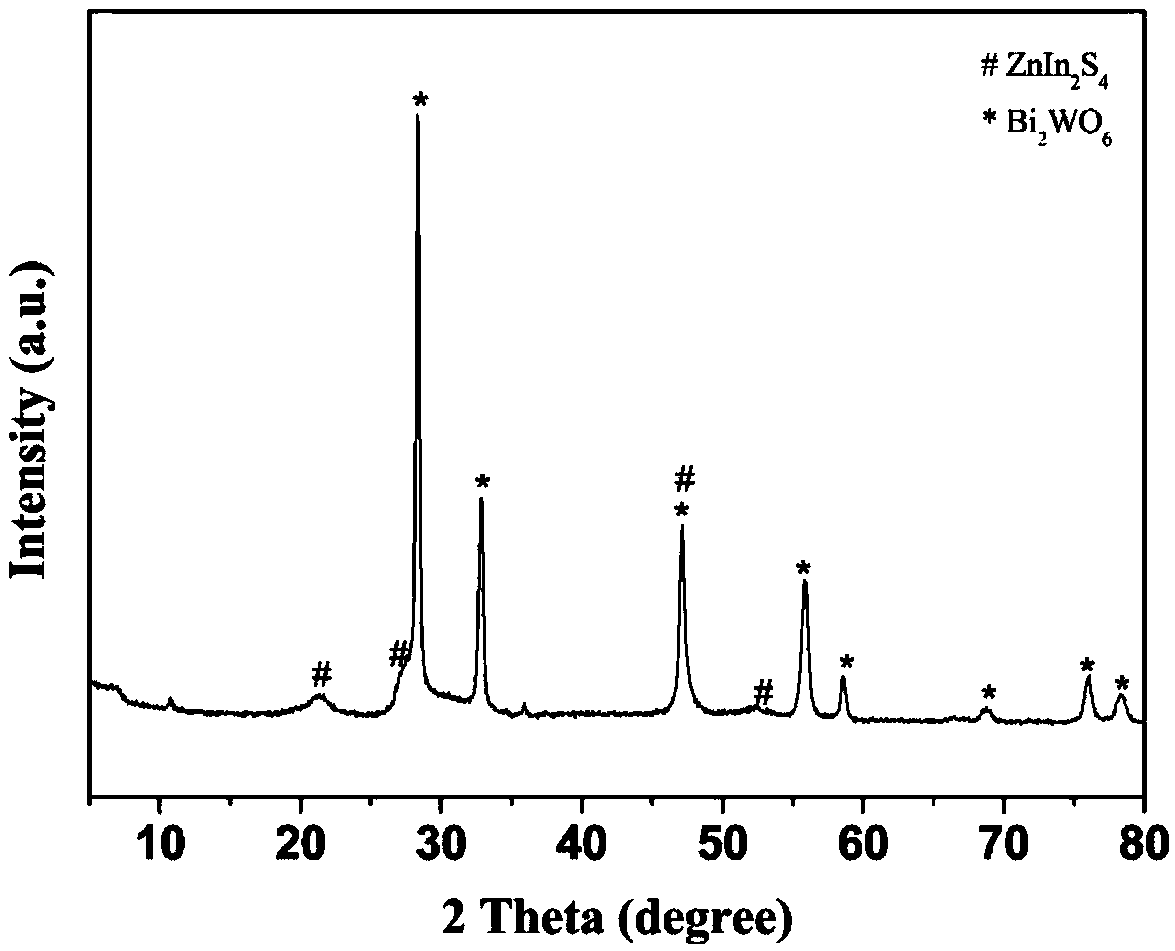

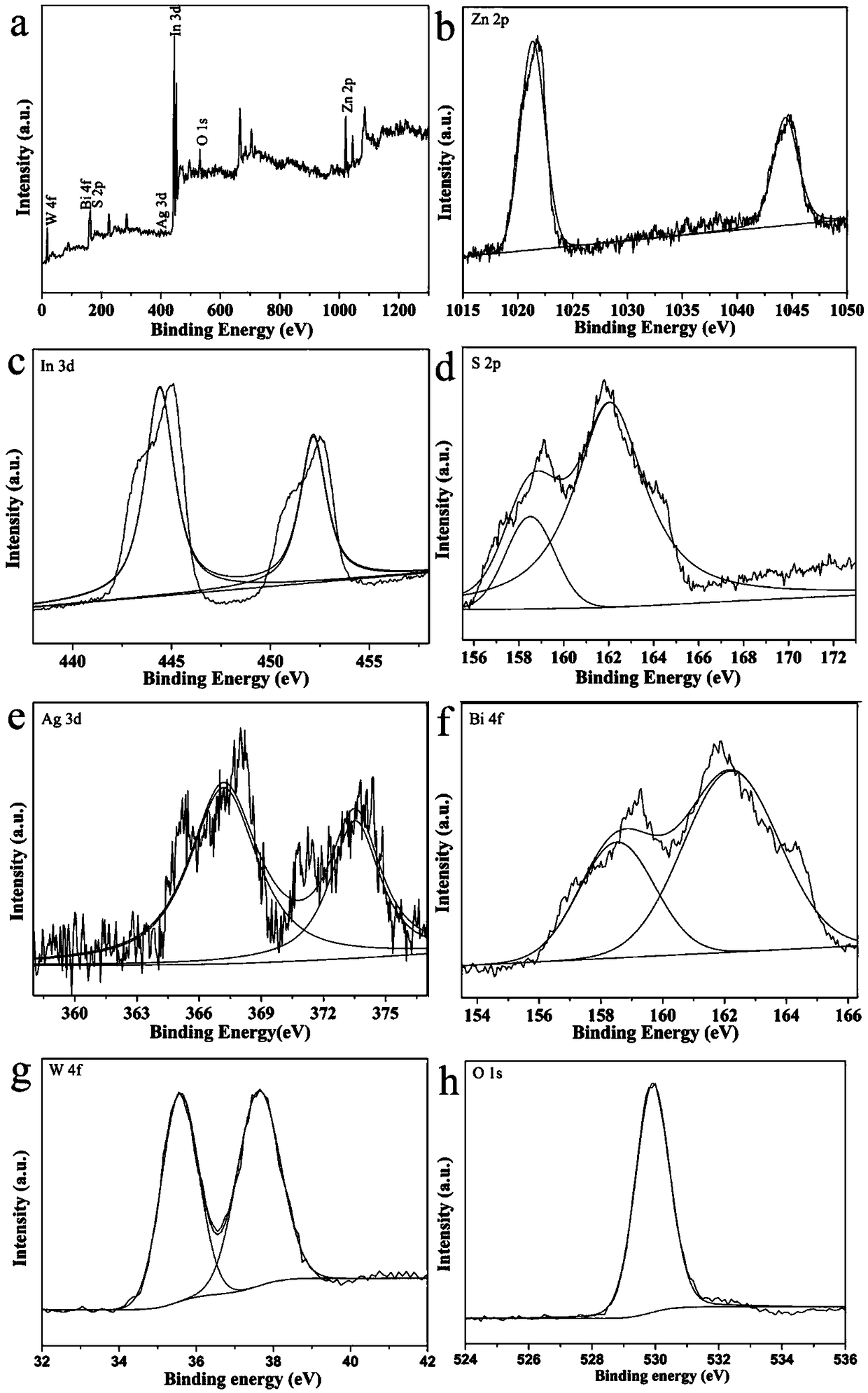

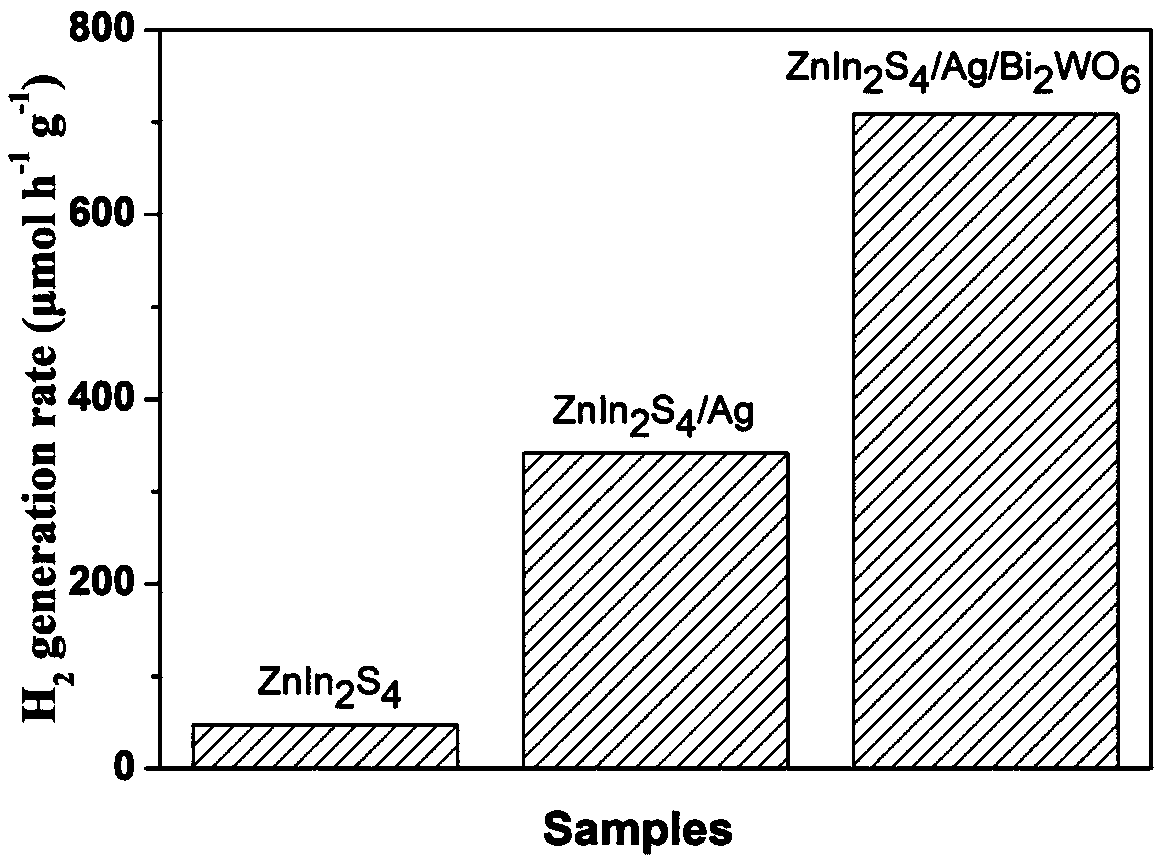

Preparation method of ZnIn2S4/Ag/Bi2WO6 compound photocatalyst with Z-type structure

A technology of znin2s4 and catalyst, which is applied in the field of inorganic environmental protection photocatalytic materials, can solve the problems of low hydrogen production efficiency, achieve the effects of improving quantum efficiency, increasing hydrogen production rate, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Prepare 50 mL of a mixed solution containing zinc nitrate with a concentration of 0.05 mol / L and indium nitrate with a concentration of 0.1 mol / L, and add 0.751 g of thioacetamide to the mixed solution under stirring. After stirring at room temperature for 2 hours, add 3 mL of hydrochloric acid solution with a concentration of 12 mol / L, continue to stir for 3 hours, then transfer to a hydrothermal reaction kettle, then put the hydrothermal reaction kettle in a dry box and react at 180°C for 1 hour. After the reaction is completed, ZnIn can be obtained by cooling, washing and drying 2 S 4 solid powder;

[0036] (2) Prepare 75 mL of sodium tungstate solution with a concentration of 0.01mol / L, and add the ZnIn prepared in step (1) to the sodium tungstate solution under stirring 2 S 4 Solid powder forms a suspension solution; slowly add 150mL bismuth nitrate solution with a concentration of 0.01mol / L to the suspension solution dropwise; adjust the pH to 9 with ammoni...

Embodiment 2

[0041] (1) Prepare 50ml of a mixed solution containing zinc nitrate with a concentration of 0.1mol / L and indium nitrate with a concentration of 0.2mol / L, and add 1.502g of thioacetamide to the mixed solution under stirring. After stirring at room temperature for 0.5h, add 1ml of hydrochloric acid solution with a concentration of 12mol / L, continue to stir for 1h, then transfer to a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a dry box and react at 160°C for 1h, and wait for the reaction to complete After cooling, washing and drying, ZnIn can be obtained 2 S 4 solid powder;

[0042] (2) Prepare 150ml of sodium tungstate solution with a concentration of 0.02mol / L, and add the ZnIn prepared in step (1) to the sodium tungstate solution under stirring 2 S 4 Solid powder forms a suspension solution; slowly add 300ml of bismuth nitrate solution with a concentration of 0.02mol / L to the suspension solution dropwise; adjust the pH to 7 with ammonia wat...

Embodiment 3

[0045] (1), preparation 50ml contains the zinc nitrate concentration that is 0.05mol / L and the mixed solution that concentration is the indium nitrate of 0.1mol / L, adds 0.751g thioacetamide in the mixed solution under stirring state. After stirring at room temperature for 1 hour, add 2ml of hydrochloric acid solution with a concentration of 12mol / L, continue to stir for 2 hours, then transfer to a hydrothermal reaction kettle, then put the hydrothermal reaction kettle in a drying oven and react at 150°C for 3 hours. After the reaction is completed, ZnIn can be obtained by cooling, washing and drying 2 S 4 solid powder;

[0046] (2) Prepare 75 mL of sodium tungstate solution with a concentration of 0.02mol / L, and add the ZnIn prepared in step (1) to the sodium tungstate solution under stirring 2 S 4 Solid powder forms a suspension solution; slowly add 150mL bismuth nitrate solution with a concentration of 0.02mol / L to the suspension solution dropwise; adjust the pH to 8 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com