Zirconium mullite boron nitride carbon side sealing plate and manufacturing method

A zirconium-mullite and manufacturing method technology, applied in the field of zirconium-mullite boron nitride carbon side seal plate and manufacturing, can solve the problems of high equipment requirements and high manufacturing costs, and achieve good wear resistance, good bonding and The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

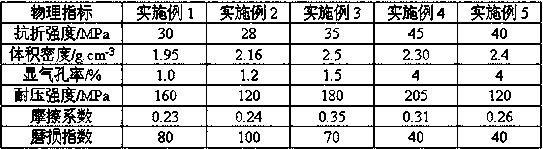

Examples

Embodiment 1

[0032] A zirconium mullite boron nitride carbon side seal plate, which is composed of the following components (mass ratio): 10% zirconium mullite, 72% hexagonal boron nitride, 15% elemental boron powder, 3% graphite, carbon fiber ( Addition) 0.3%, thermosetting phenolic resin (addition) 20%.

[0033] Step 1) Premix hexagonal boron nitride, graphite, carbon fiber and some zircon mullite fine powder according to the above ratio to obtain powder A; put the additives in the carbon binder and stir evenly to obtain a composite binder B;

[0034] Step 2) Put the remaining zircon mullite in a high-speed mixer at a speed of 100 rpm, and add composite binder B, stir and mix evenly, then add powder A to fully mix to obtain a mixed uniform material, After the material is trapped for 24 hours, it is formed by vacuum pressure at room temperature, and the vacuum forming pressure is 300MPa;

[0035] Step 3) The molded product is cured at 200°C, fired at 1200°C for 10 hours, then impregnate...

Embodiment 2

[0037] A zirconium mullite boron nitride carbon side sealing plate, which is composed of the following components (mass ratio): 20% zirconium mullite, 67% hexagonal boron nitride, 10% elemental boron powder, 3% graphite, carbon fiber ( Addition) 0.3%, thermosetting phenolic resin (addition) 15%.

[0038] The manufacturing method of the above-mentioned zirconium mullite boron nitride carbon side sealing plate:

[0039] Step 1) Premix hexagonal boron nitride, graphite, carbon fiber and some zircon mullite fine powder according to the above ratio to obtain powder A; put the additives in the carbon binder and stir evenly to obtain a composite binder B;

[0040] Step 2) Put the remaining zircon mullite in a high-speed mixer at a speed of 100 rpm, and add composite binder B, stir and mix evenly, then add powder A to fully mix to obtain a mixed uniform material, After the material is trapped for 24 hours, it is formed by vacuum pressure at room temperature, and the vacuum forming p...

Embodiment 3

[0043] A zirconium mullite boron nitride carbon side seal plate, which is composed of the following components (mass ratio): 30% zirconium mullite, 62% hexagonal boron nitride, 5% elemental boron powder, 3% graphite, carbon fiber ( Addition) 0.3%, thermosetting phenolic resin (addition) 12%.

[0044] The manufacturing method of the above-mentioned zirconium mullite boron nitride carbon side sealing plate:

[0045] Step 1) Premix hexagonal boron nitride, graphite, carbon fiber and some zircon mullite fine powder according to the above ratio to obtain powder A; put the additives in the carbon binder and stir evenly to obtain a composite binder B;

[0046] Step 2) Put the remaining zircon mullite in a high-speed mixer at a speed of 100 rpm, and add composite binder B, stir and mix evenly, then add powder A to fully mix to obtain a mixed uniform material, After the material is trapped for 24 hours, it is formed by vacuum pressure at room temperature, and the vacuum forming press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com