Electrolytic aluminum tank continuous temperature measuring method

An electrolytic aluminum tank and temperature measurement technology, which is applied in the field of electrolytic aluminum, can solve the problems of continuous online detection and temperature measurement methods that cannot meet the accuracy requirements, and achieve the effects of improving labor productivity and ensuring equipment and personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The second-level computer model in the embodiment adopts the existing technology, such as the calculation model of the temperature field of electrolytic aluminum of Central South University.

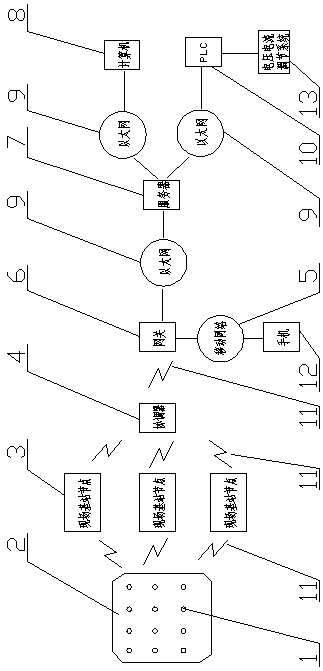

[0028] A method for continuous temperature measurement of an electrolytic aluminum tank, such as figure 1 shown, including the following steps:

[0029] Step 1. According to the electrolytic aluminum process and the shape of the electrolytic aluminum tank 2, arrange a matrix-type non-dead-angle temperature measurement unit array at the bottom and key sides of the electrolytic aluminum tank 2, and install a wireless temperature sensor 1 on the temperature measurement unit array, continuous and uninterrupted Measure the tank temperature accurately;

[0030] Step 2, the wireless temperature sensor 1 sends a series of continuous temperature signals measured to the on-site base station node 3 through the first wireless network 11, and the on-site base station node 3 sends the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com