Paint spraying equipment for automobile hub coating production line

A coating production line, automobile wheel hub technology, applied in spray booths, spraying devices, etc., can solve the problems of not meeting the needs of use, general performance of painted products, poor coating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

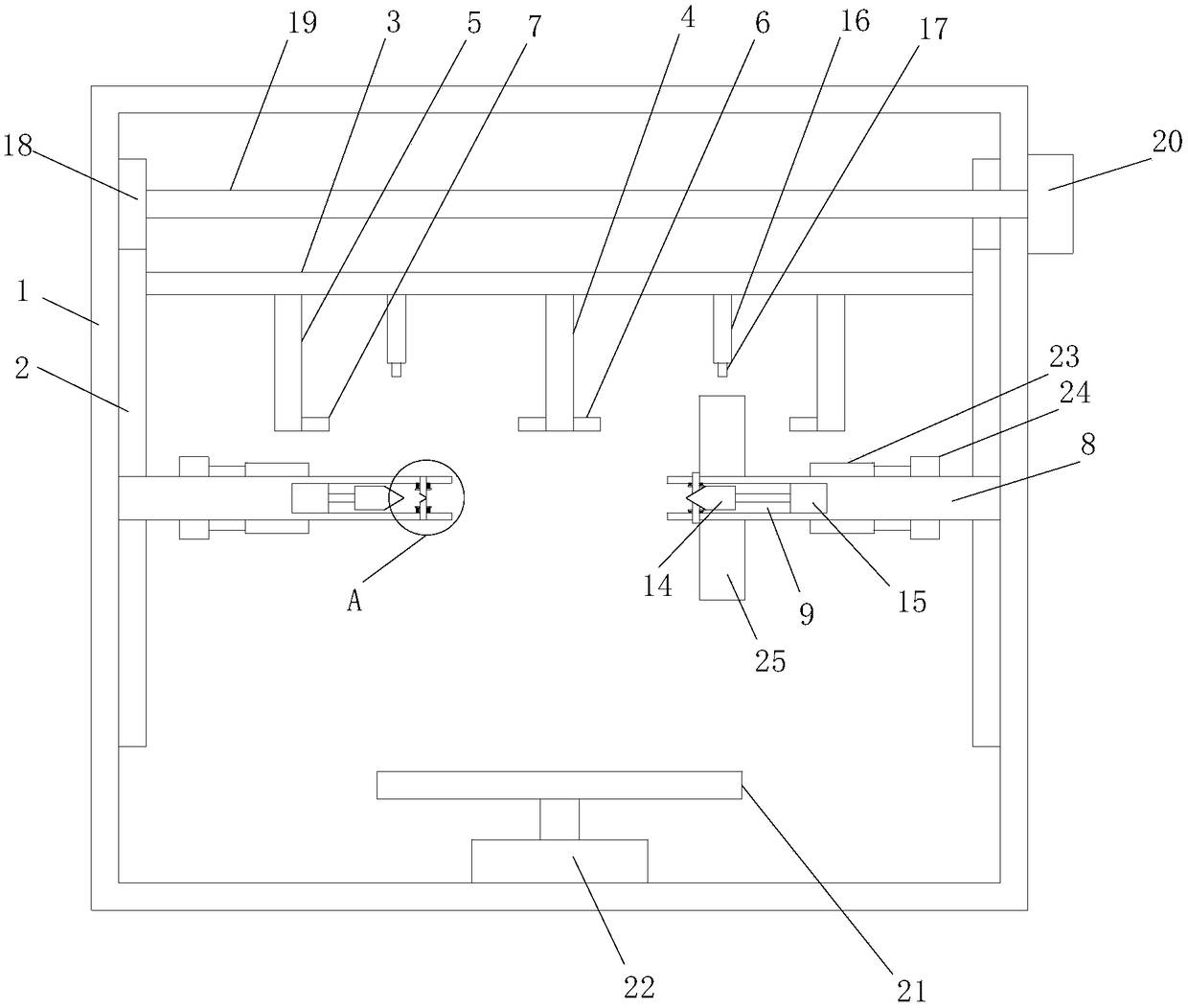

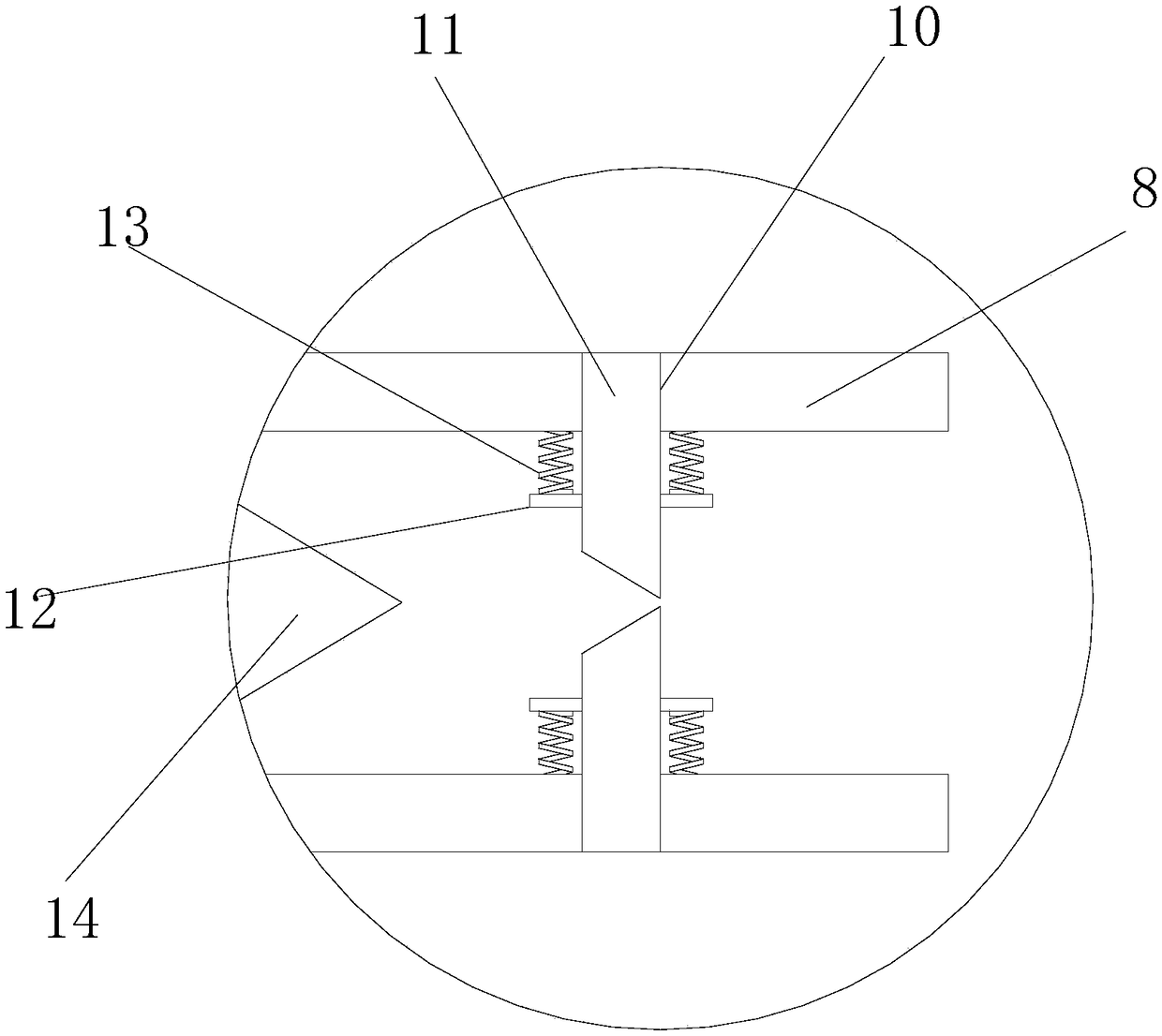

[0015] Such as figure 1 , figure 2 As shown, figure 1 It is a schematic diagram of the structure of a paint spraying equipment for an automobile wheel coating production line proposed by the present invention; figure 2 for figure 1 Schematic diagram of enlarged structure at middle A.

[0016] Reference figure 1 , figure 2 , The present invention proposes a painting equipment for automobile wheel coating production line, comprising a painting box 1 and a painting mechanism and a supporting mechanism arranged in the painting box 1, wherein:

[0017] The painting mechanism includes two rotating discs 2, a power unit, a connecting rod 3, a first painting column 4 and two second painting columns 5. The two turntables 2 are arranged oppositely, and the two turntables 2 are respectively rotatably installed on the inner walls of both sides of the paint spraying box 1. The central axes of the two turntables 2 are arranged horizontally and the central axes of the two turntables 2 coinci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com