Filter connector capable of being taken and sent

A filter connector, a desirable technology, applied in the direction of connection, connection with permanent deformation effect, high-frequency structural connection, etc., can solve problems such as poor maintainability, and achieve the effects of high assembly efficiency, convenient maintenance and replacement, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments of the description.

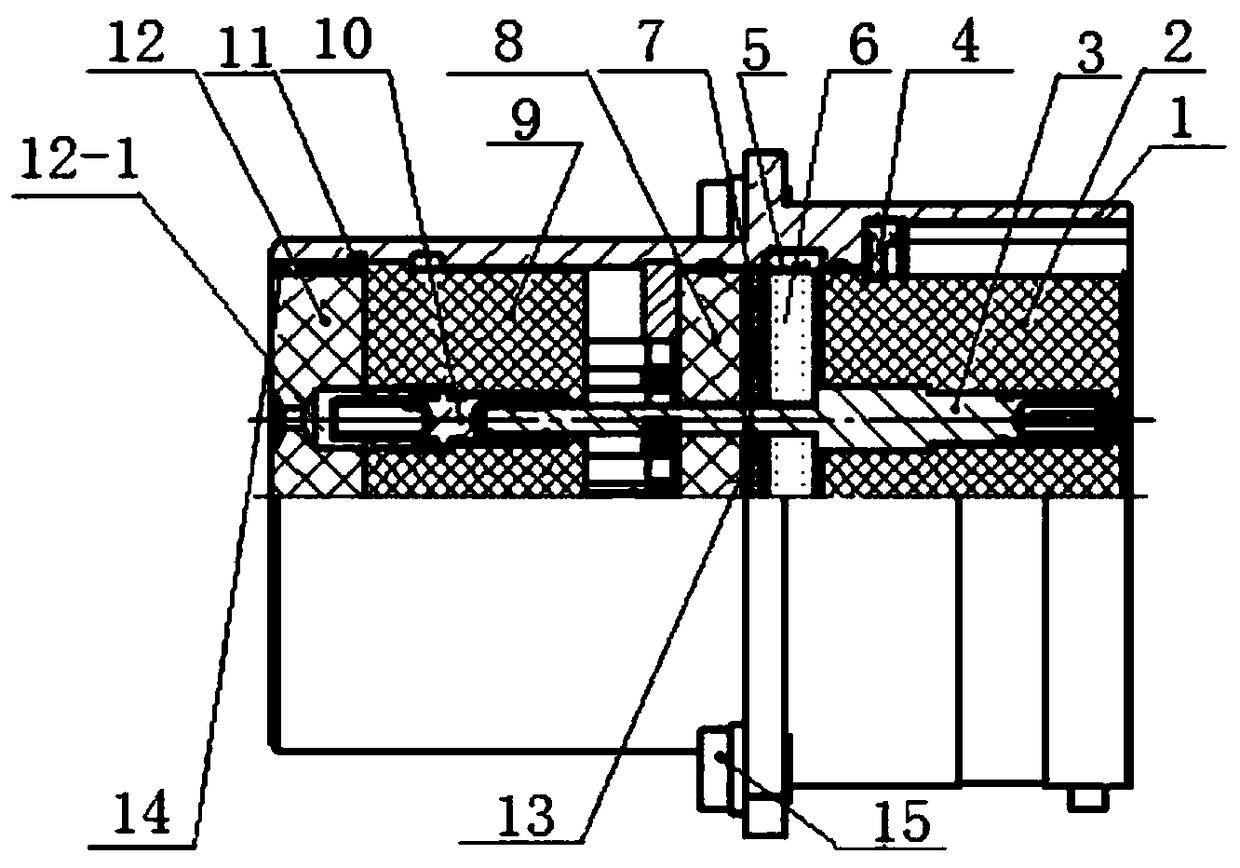

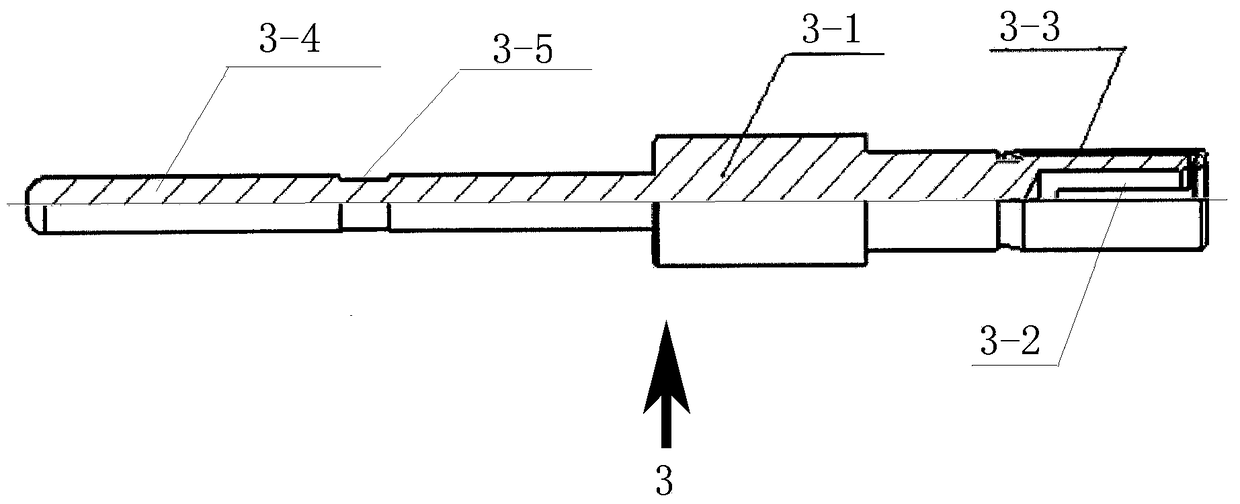

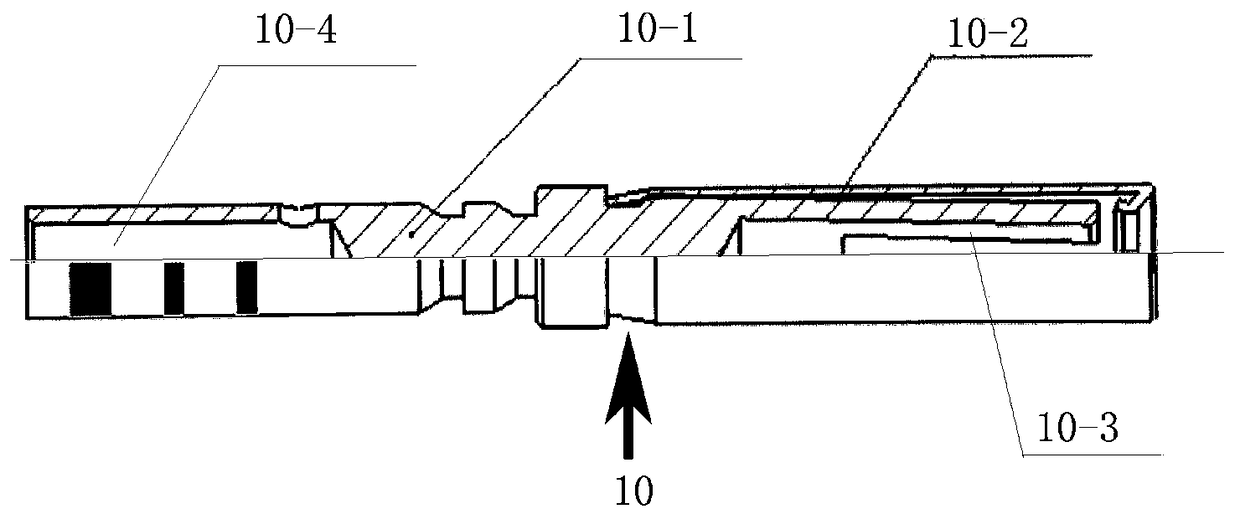

[0030] refer to Figure 1-Figure 4 , a detachable filter connector, the filter connector includes a housing 1, an insulator 2 in front of the hole, a main jack 3, a sealing ring 4, a grounding reed 5, a filter plate 6, a rubber pad 7, a rear insulator 8, Short jack insulator 9, short jack 10, circlip 11 and sealing wire body 12; said insulator 2 before the hole is installed inside the front end of the housing 1, and a seal is installed between the insulator 2 before the hole and the inside of the housing 1 Ring 4, the main jack 3 and the filter plate 6 are welded and put into the insulator 2 in front of the hole as a whole, and the filter plate 6 is connected to the shell 1 through the grounding reed 5;

[0031] A rubber pad 7 is installed on the left end of the filter plate 6, and the rear insulator 8 is bonded and fixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com