Ceramic shower tray produced from waste and production method thereof

A production method and shower tray technology, applied in the field of sanitary ceramics, can solve the problems of large consumption of raw materials and energy, high production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

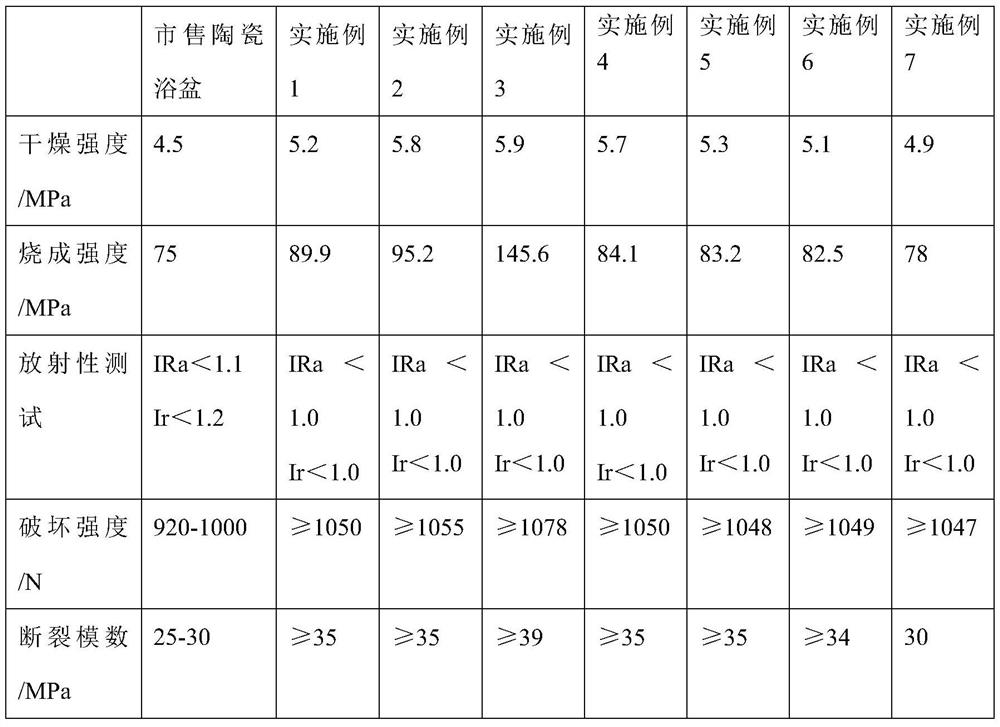

Examples

Embodiment 1

[0048] A ceramic shower tray produced from waste, the raw materials of the ceramic shower tray include the following components in parts by weight:

[0049] 40 parts of quartz waste sand, 10 parts of waste porcelain, 10 parts of clay, 4 parts of raw material, 5 parts of feldspar, 8 parts of coal gangue, 0.5 part of talc, and 0.5 part of electrolyte;

[0050] The electrolyte is composed of water glass and soda ash, and the mixing ratio is 3:2 by weight.

[0051] Preferably, the raw materials of the ceramic shower tray also include the following components in parts by weight:

[0052] 0.1 part of carboxymethyl starch, 0.2 part of sodium tripolyphosphate, 4 parts of montmorillonite.

[0053] Preferably, the raw materials of the ceramic shower tray also include the following components in parts by weight:

[0054] 0.1 part of polyvinyl alcohol, 0.5 part of sodium alginate, 0.1 part of xanthan gum.

[0055] The production method of the ceramic shower tray produced by using waste...

Embodiment 2

[0064] A ceramic shower tray produced from waste, the raw materials of the ceramic shower tray include the following components in parts by weight:

[0065] 65 parts of quartz waste sand, 15 parts of waste porcelain, 15 parts of clay, 6 parts of raw material, 8 parts of feldspar, 8 parts of coal gangue, 0.5 part of talc, and 0.5 part of electrolyte;

[0066] The electrolyte is composed of water glass and soda ash, and the mixing ratio is 3:2 by weight.

[0067] Preferably, the raw materials of the ceramic shower tray also include the following components in parts by weight:

[0068] 0.5 parts of carboxymethyl starch, 0.4 parts of sodium tripolyphosphate, and 8 parts of montmorillonite.

[0069] Preferably, the raw materials of the ceramic shower tray also include the following components in parts by weight:

[0070] 0.4 parts of polyvinyl alcohol, 5 parts of sodium alginate, and 0.5 parts of xanthan gum.

[0071] The production method of the ceramic shower tray produced by ...

Embodiment 3

[0080] A ceramic shower tray produced from waste, the raw materials of the ceramic shower tray include the following components in parts by weight:

[0081] 55 parts of quartz waste sand, 12 parts of waste porcelain, 12 parts of clay, 5 parts of raw material, 6 parts of feldspar, 8 parts of coal gangue, 0.5 part of talc, and 0.5 part of electrolyte;

[0082] The electrolyte is composed of water glass and soda ash, and the mixing ratio is 3:2 by weight.

[0083] Preferably, the raw materials of the ceramic shower tray also include the following components in parts by weight:

[0084] 0.3 parts of carboxymethyl starch, 0.3 parts of sodium tripolyphosphate, 6 parts of montmorillonite.

[0085] Preferably, the raw materials of the ceramic shower tray also include the following components in parts by weight:

[0086] 0.3 parts of polyvinyl alcohol, 2.5 parts of sodium alginate, and 0.4 parts of xanthan gum.

[0087] The production method of the ceramic shower tray produced by us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com