Steam distribution structure for active carbon production

A technology of activated carbon production and steam, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of low energy utilization rate, low activated carbon production capacity, large heat consumption, etc., to achieve high overall structural strength, prevent jumping, Resolving the effect of a uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

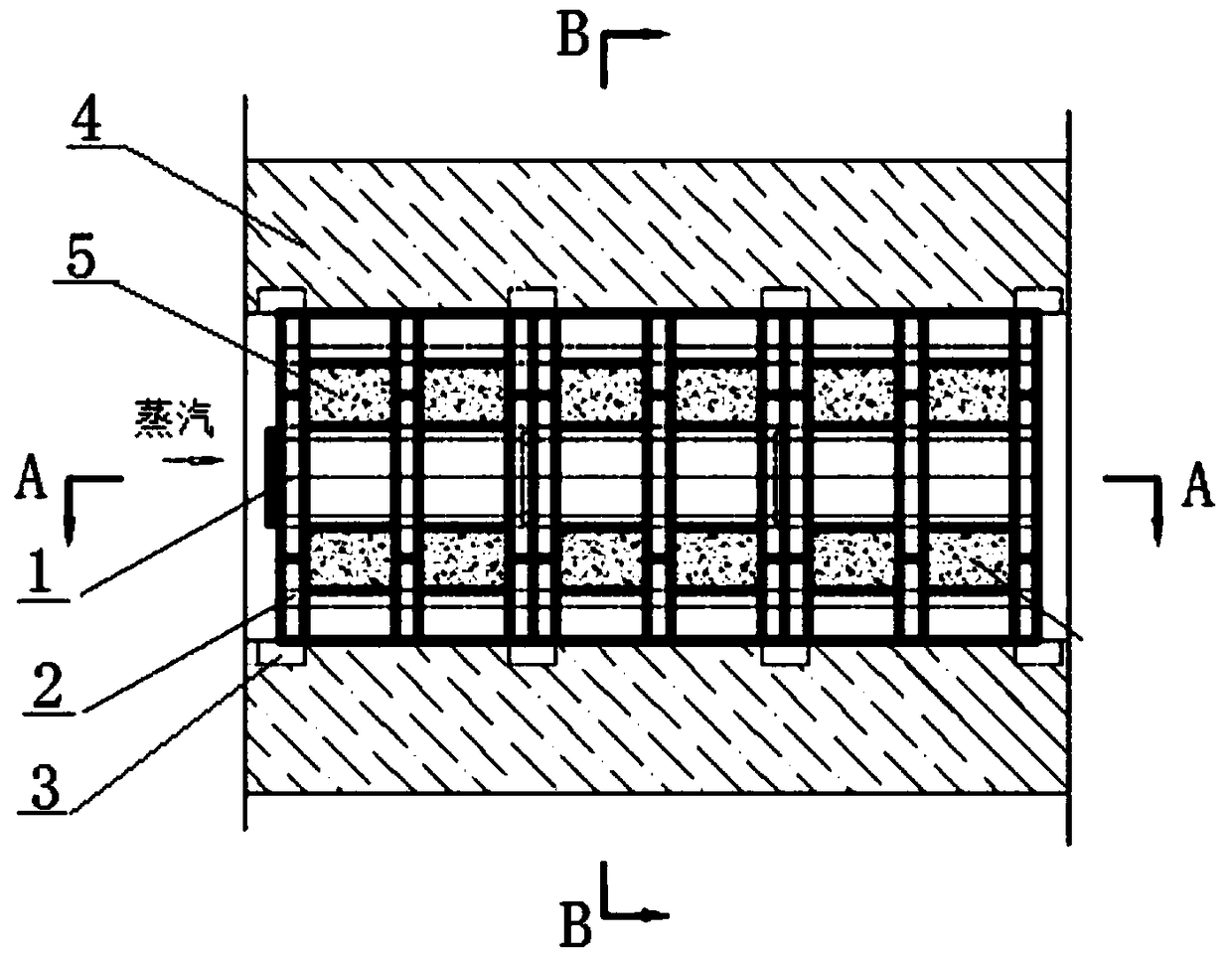

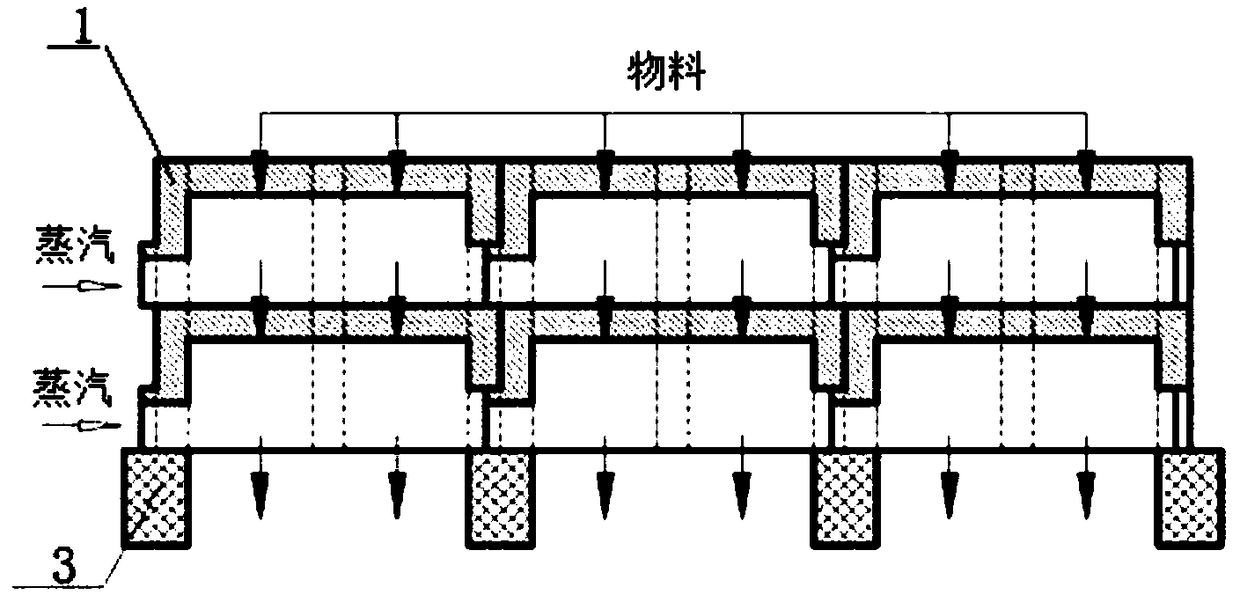

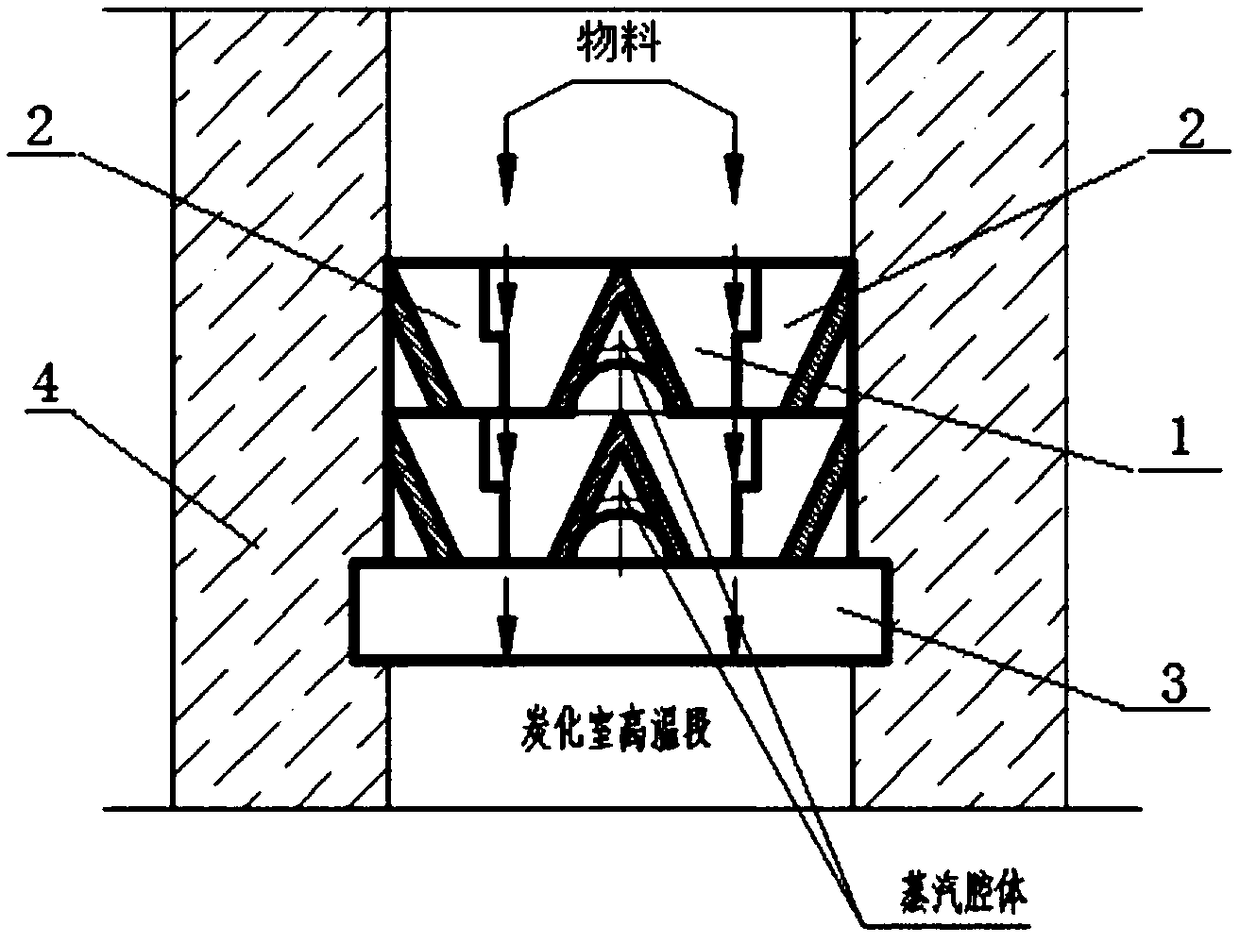

[0029] Such as Figure 1-Figure 3 As shown, a kind of steam gas distribution structure for the production of activated carbon according to the present invention is provided with one to multiple layers along the high-temperature section of the carbonization chamber of the retort furnace; the steam gas distribution structure consists of gas distribution brick 1, channel brick 2 and Composed of beams 3; at least one air distribution brick 1 is arranged along the width direction of the carbonization chamber, and each air distribution brick is composed of a plurality of air distribution bricks 1, and is arranged along the length direction of the carbonization chamber; The two sides are arranged side by side and connected with the carbonization chamber wall 4; the beam 3 supports the gas distribution brick 1 and the channel brick 2; between the gas dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com