Composite solid electrolyte and its preparation method and application

A solid electrolyte, solid electrolyte layer technology, applied in electrolytes, circuits, electrical components, etc., can solve the problems of leakage of liquid electrolyte, reduction of bulk ionic conductivity, narrow electrochemical window, etc., to inhibit the growth of lithium dendrites, The effect of easy industrial production and wide electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

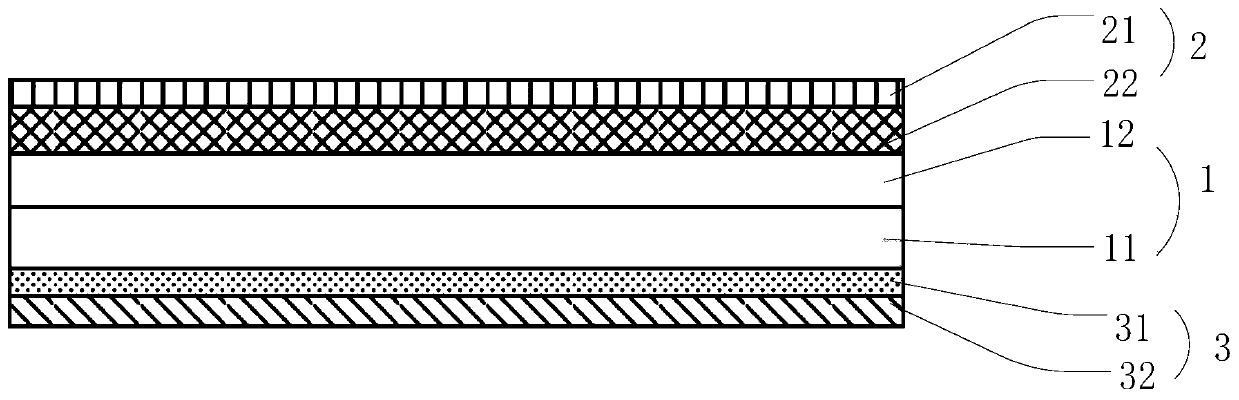

[0056] As an optional technical solution, the preparation method of the composite solid electrolyte includes the following steps:

[0057] (a) adding the polymer matrix and lithium salt to the solvent, and dispersing to obtain the first mixed solution; the dispersion can be carried out by stirring to obtain a uniformly dispersed solution, such as mechanical stirring, magnetic stirring, etc.;

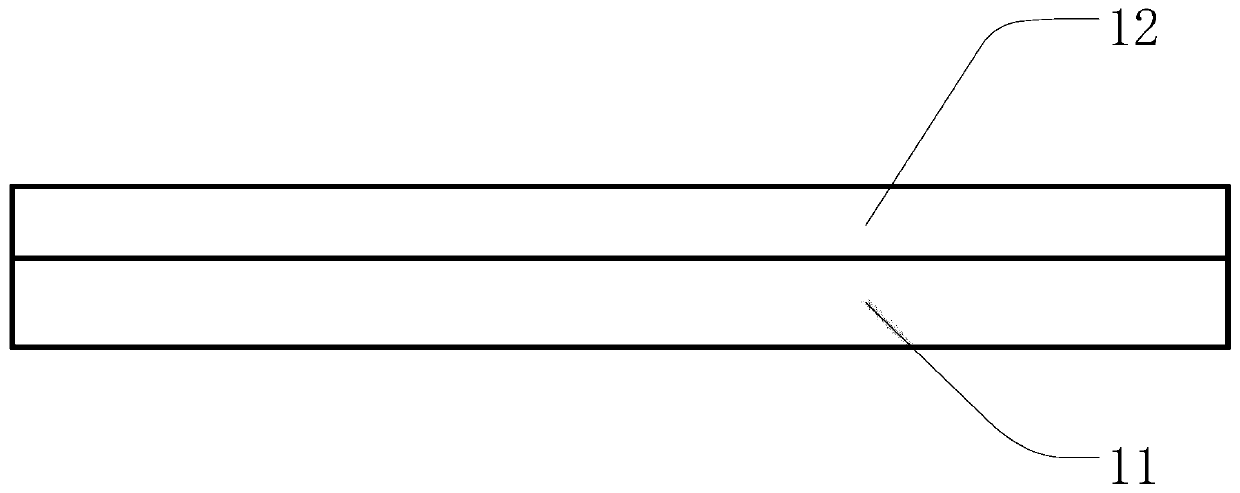

[0058] (b) adding part of the first mixed solution to the mold, volatilizing the solvent in vacuum, heating and drying in vacuum to obtain the first solid electrolyte layer;

[0059] (c) Add an inorganic solid electrolyte to part of the first mixed solution and disperse to obtain a second mixed solution; the dispersion can be carried out by stirring to obtain a uniformly dispersed solution, such as mechanical stirring, magnetic stirring, etc.; the inorganic solid electrolyte is usually powdered After adding, it will be evenly dispersed;

[0060] (d) Pour the second mixed solution into a...

Embodiment 1

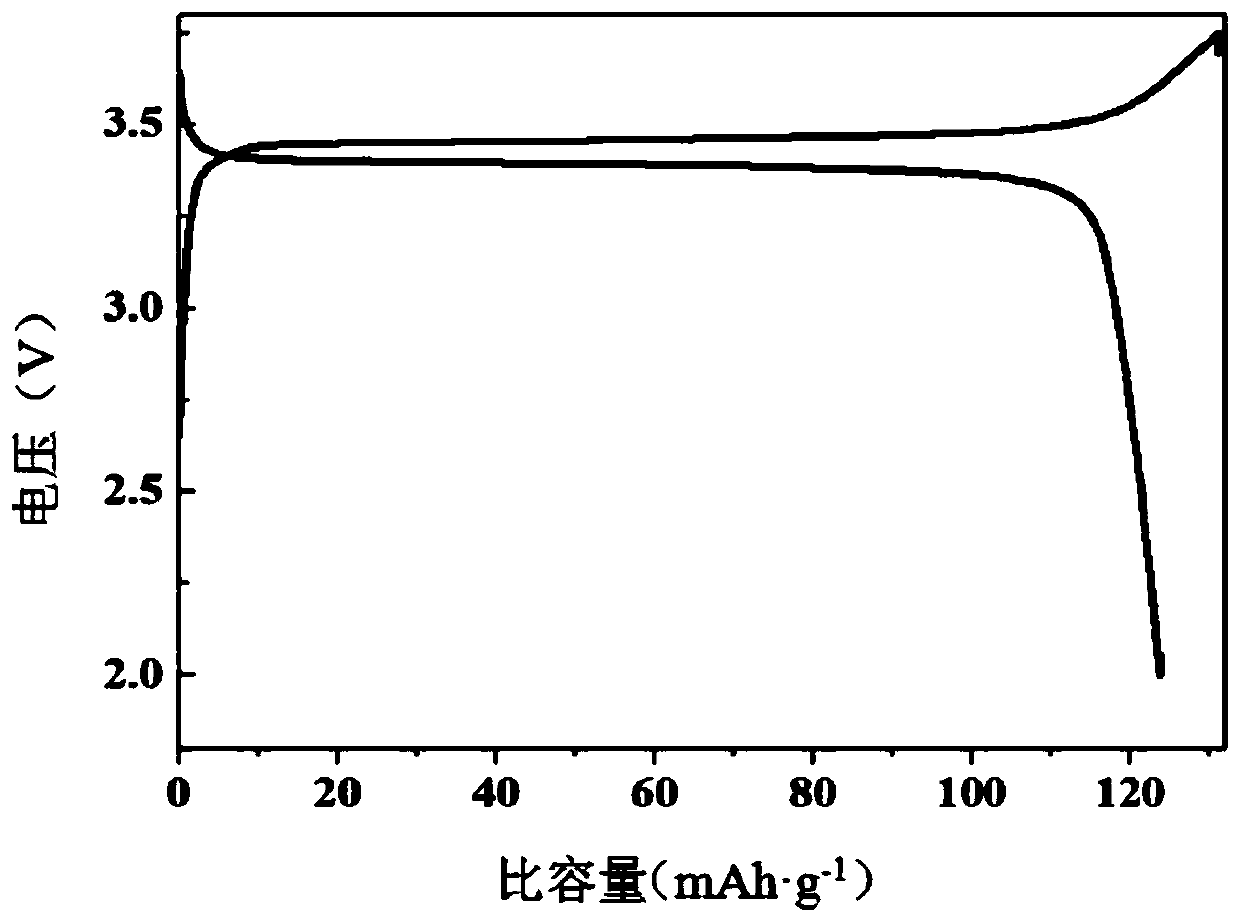

[0070] Polyethylene oxide is selected as the polymer matrix, lithium bistrifluoromethanesulfonimide is the lithium salt, and the mass ratio of the polymer matrix to the lithium salt is 0.5:1;

[0071] Polyethylene oxide and lithium bistrifluoromethanesulfonimide were dried at 50°C and 120°C for 24 hours, respectively, and then polyethylene oxide and lithium bistrifluoromethanesulfonimide were dissolved in acetonitrile and dispersed uniformly to obtain the first a mixed solution;

[0072] Pour the prepared first mixed solution into a polytetrafluoro mold to volatilize the acetonitrile solvent in vacuum, and dry it in vacuum at 50° C. to obtain the first solid electrolyte layer, whose thickness range is set between 10 μm and 50 μm.

Embodiment 2

[0074] Highly selective polypropylene oxide is used as the molecular matrix, lithium hexafluorophosphate is selected as the lithium salt, and the mass ratio of the two is 1:1;

[0075] For the preparation method of the first solid electrolyte layer in Example 2, refer to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com