Small-sized and high-reliability circuit breaker structure

A circuit breaker, small size technology, applied in the field of circuit breaker structure, can solve the problems of increasing the bonding strength, extinguishing the arc, reducing the creepage distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with specific embodiments.

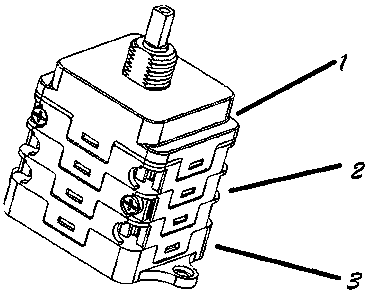

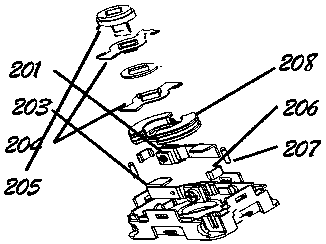

[0040] like Figure 1-18 As shown, in one embodiment, a small-sized and high-reliability circuit breaker structure includes: a rotating assembly (1), a contact assembly (2) providing a current path, and a base assembly (3). The contact assembly is at least There are two layers, with moving contacts and static contacts respectively. The circuit plane passing through the two static contacts and the rotation axis of the contact assembly on the same layer is parallel to the side of the casing, and the wiring pieces connected to the static contacts are respectively arranged on the Both sides of the circuit plane; and / or, a built-in bridging piece, when bridging is required, one contact piece of the built-in bridging piece is arranged at the static contact piece position of one layer, and the other contact piece is arranged at the other layer of the adjacent layer The misplace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com