Pre-warming device for steel plate pretreatment line

A pretreatment and steel plate technology, which is applied in the field of auxiliary equipment for steel plate pretreatment lines, can solve problems such as waste of production costs, impact on shot blasting, and prolonging preheating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

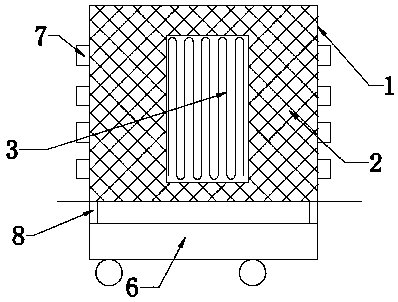

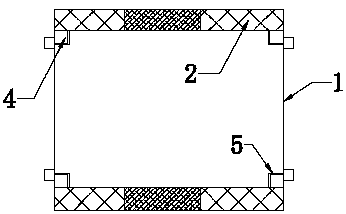

[0010] The steel plate pretreatment line preheating device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] As shown in the figure, the steel plate pretreatment line preheating device of the present invention includes a preheating room 1 located in front of the preheating room. The left and right side walls of the preheating room 1 are provided with insulation layers 2, and the left and right sides of the preheating room 1 A coil pipe 3 located in the middle of the heat preservation layer is also arranged on the side wall, and the coil pipe 3 can heat and heat the pre-heating chamber through the control device. The guide rail 4 arranged vertically, the steel plate seat 5 that can vertically lift on the guide rail is arranged on the guide rail 4, and the bottom of the preheating room 1 is provided with a mobile trolley 6, and the mobile trolley 6 can output the steel plate after pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com