A highway height limit gantry and its height limit adjustment method

A high mast and height-limiting technology, which is applied in the field of highway height-limiting masts and height-limiting adjustments, can solve problems such as unsafe, cumbersome operations, and low precision, achieving high safety, ensuring lifting stability, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

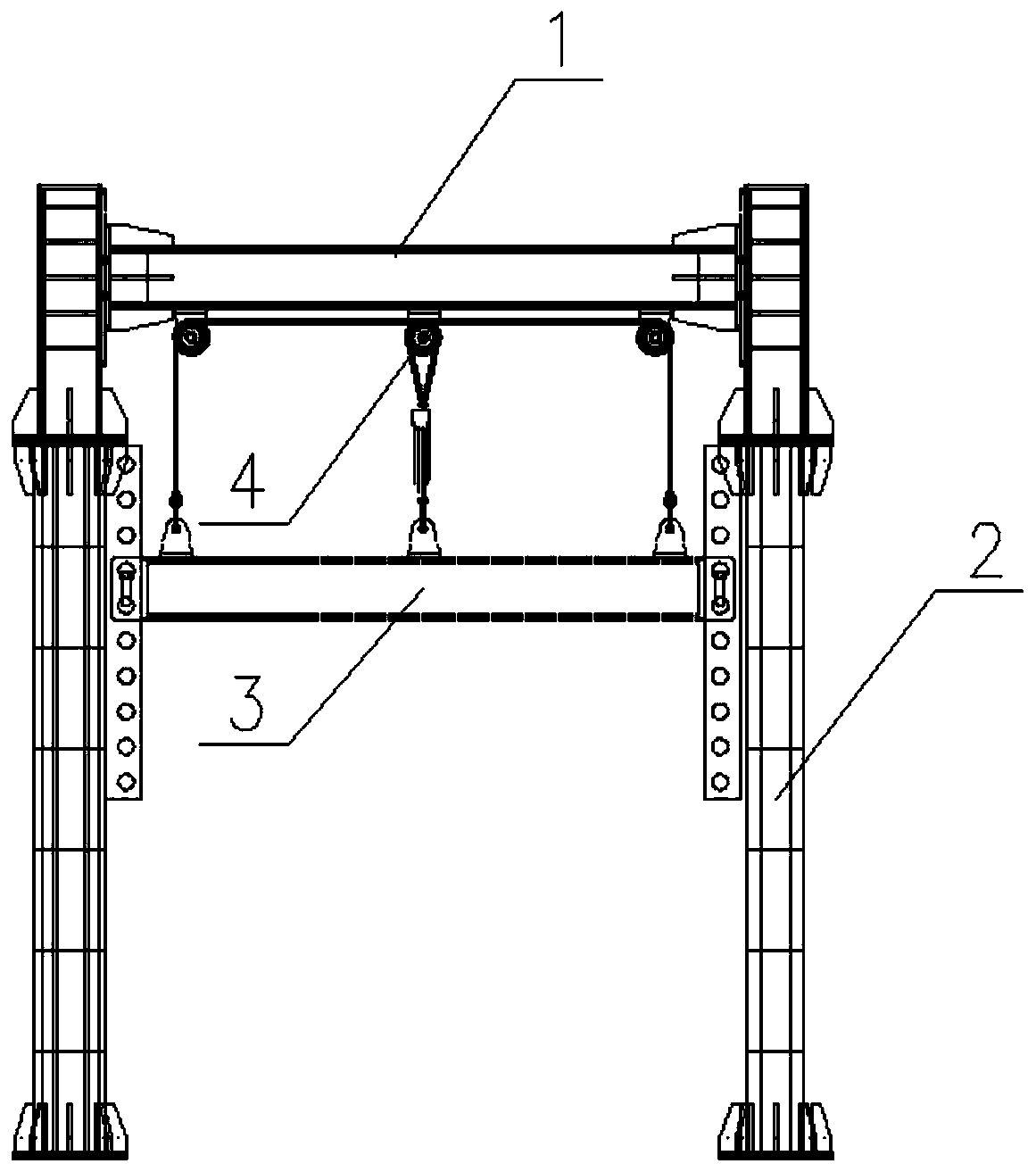

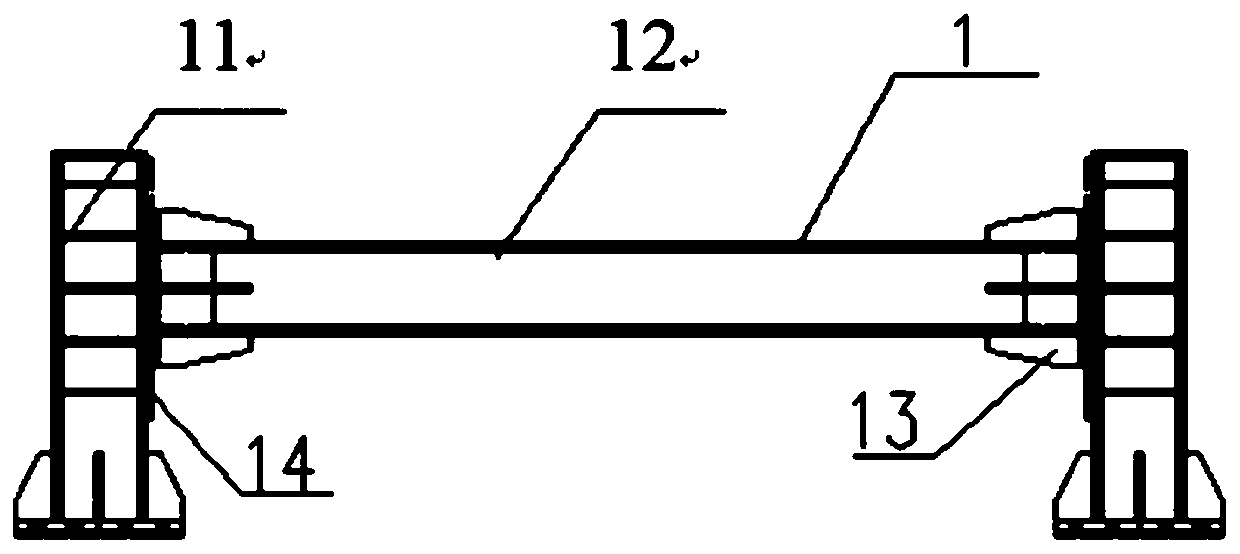

[0043] see figure 1 As shown, the embodiment of the present invention provides a highway height limit gantry, including:

[0044] The upper main beam assembly 1 includes two vertical beams 11 and a cross beam 12 horizontally erected between the two vertical beams 11;

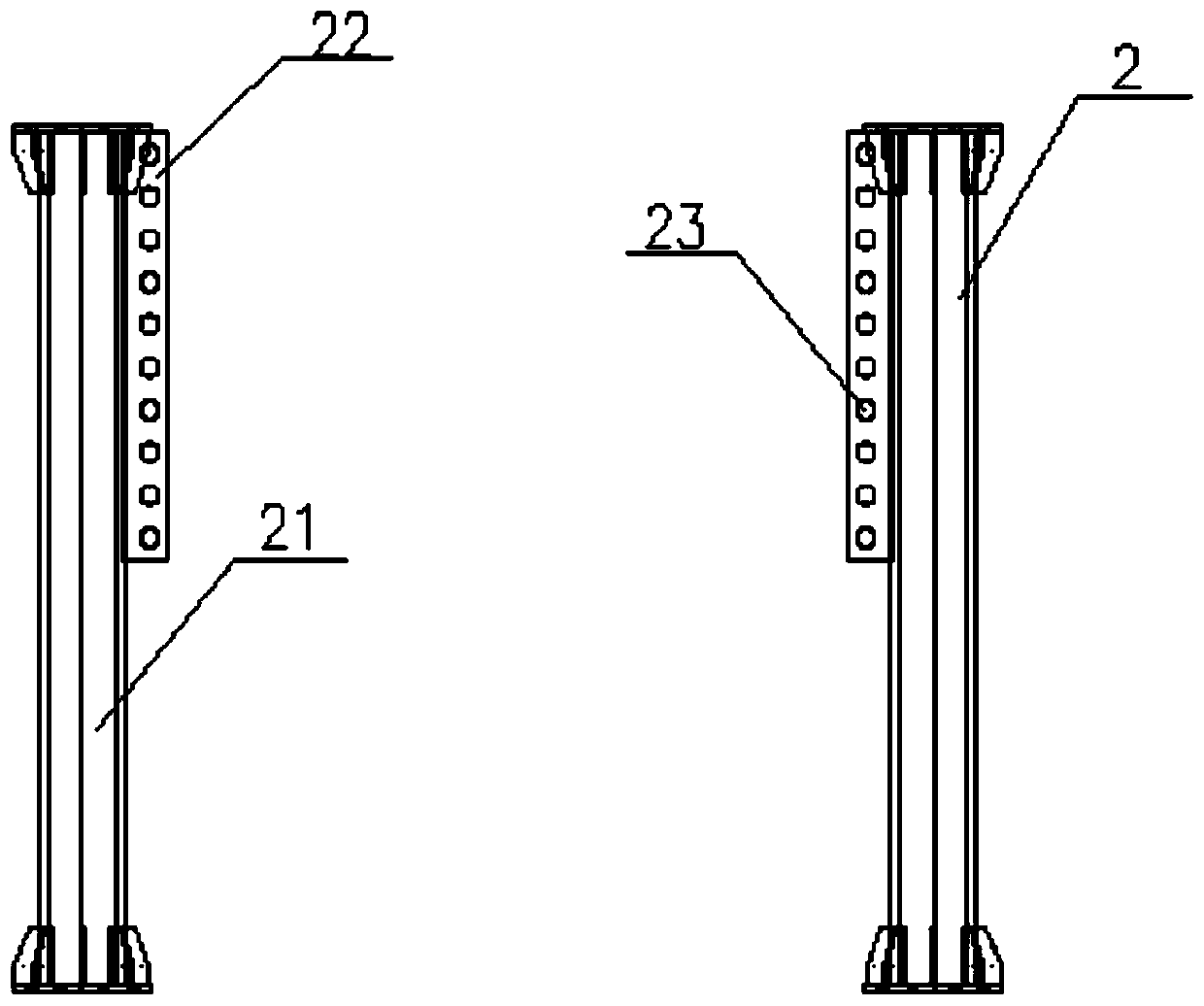

[0045] see image 3 As shown, the lower support assembly 2 includes two vertical beam support beams 21 and two hole-shaped height rulers 22. The two vertical beam support beams 21 are respectively arranged below the two vertical beams 11, and the two hole-shaped height rulers 22 are respectively It is fixed on the vertical beam support beam 21 along the height direction of the two vertical beam support beams 21; the hole-shaped height ruler 22 is provided with a plurality of vertically arranged round holes 23; the two hole-shaped height rulers 22 are fixed on the lower support assembly 2 On the same height, a plurality of circular holes 23 on the two hole-shaped height gauges 22 are located at the same height....

Embodiment 2

[0062] The embodiment of the present invention also discloses a height limit adjustment method for a highway height limit gantry:

[0063] The process of promoting the movable height limit assembly 3 includes:

[0064] Tighten the chain block 46 to make the lifting drive assembly 4 rise;

[0065] The two ends of the movable height limiting assembly 3 are fixed in the circular hole 23 of the hole-shaped height gauge 22;

[0066] Release the chain block 46 until the chain block 46 is not stressed.

[0067] The process of descending the movable height limit component 3 includes:

[0068] Pull the chain block 46 in reverse to make the lifting drive assembly 4 descend;

[0069] The two ends of the movable height limiting assembly 3 are fixed in the circular hole 23 of the hole-shaped height gauge 22;

[0070] Release the chain block 46 until the chain block 46 is not stressed.

Embodiment 3

[0072] The highway height limit gantry also includes two clamping shafts 5, and a clamping shaft fixing hole 31 is respectively provided at both ends of the movable height limiting assembly 3, and the clamping shaft 5 passes through one of the clamping shaft fixing holes 31 and the hole-shaped height gauge 22. Round hole 23. The height limit adjustment method of the highway height limit gantry is as follows:

[0073] 1. Adjust the height limit value, lift the movable height limit component 3 to the predetermined height, and allow higher motor vehicles to pass through.

[0074] First, slightly tighten the chain block 46, so that the lifting drive assembly 4 is in a stressed state; then continue to tighten the chain block 46, so that the movable height limit assembly 3 rises upward by 5 to 10 cm; then rotate the two clamping shafts 590 °Take out the card shaft 5; continue to tighten the chain block 46, so that the movable limit rod rises to the corresponding height hole on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com