Thumb wheel torque automatic force measuring device and method

A force measuring device and thumb wheel technology, applied in measuring devices, torque measurement, power measurement and other directions, can solve the problems of inability to meet the needs of modern industries, low detection efficiency, difficult detection, etc., to improve product detection efficiency and automation. High, avoid product damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

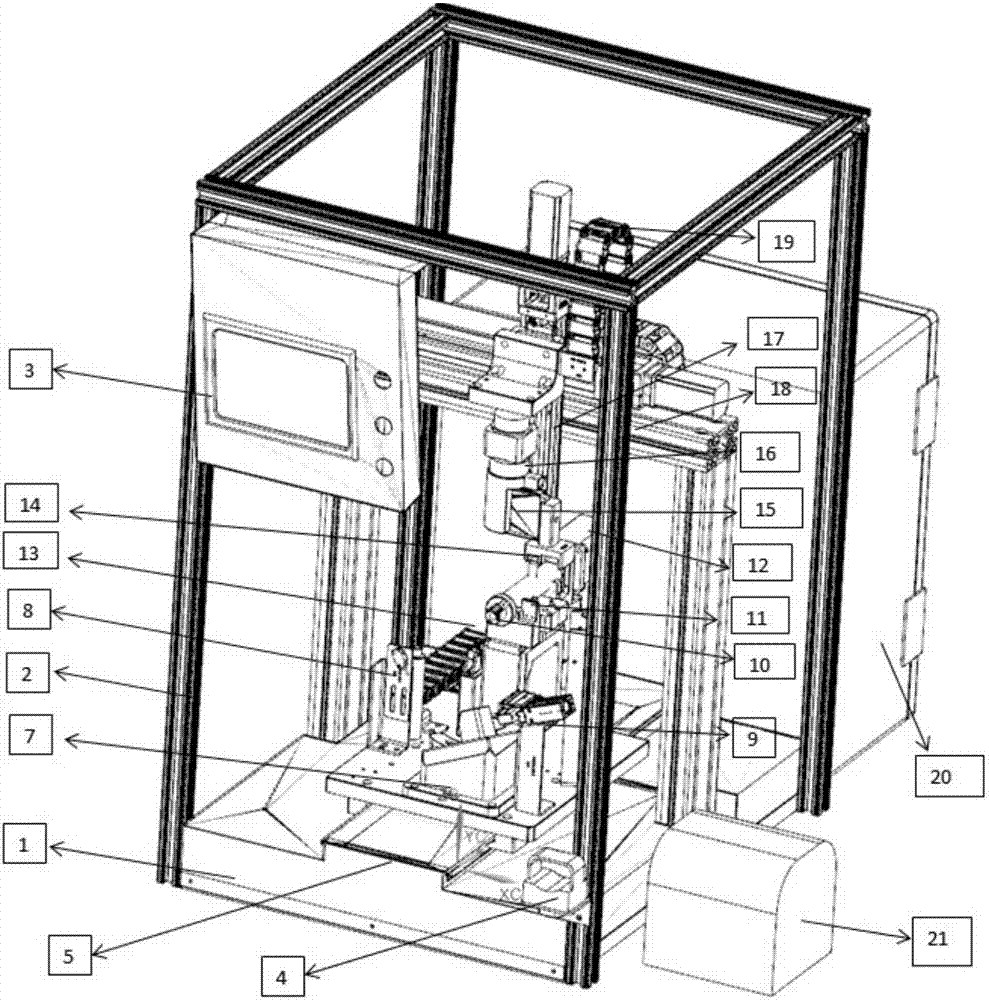

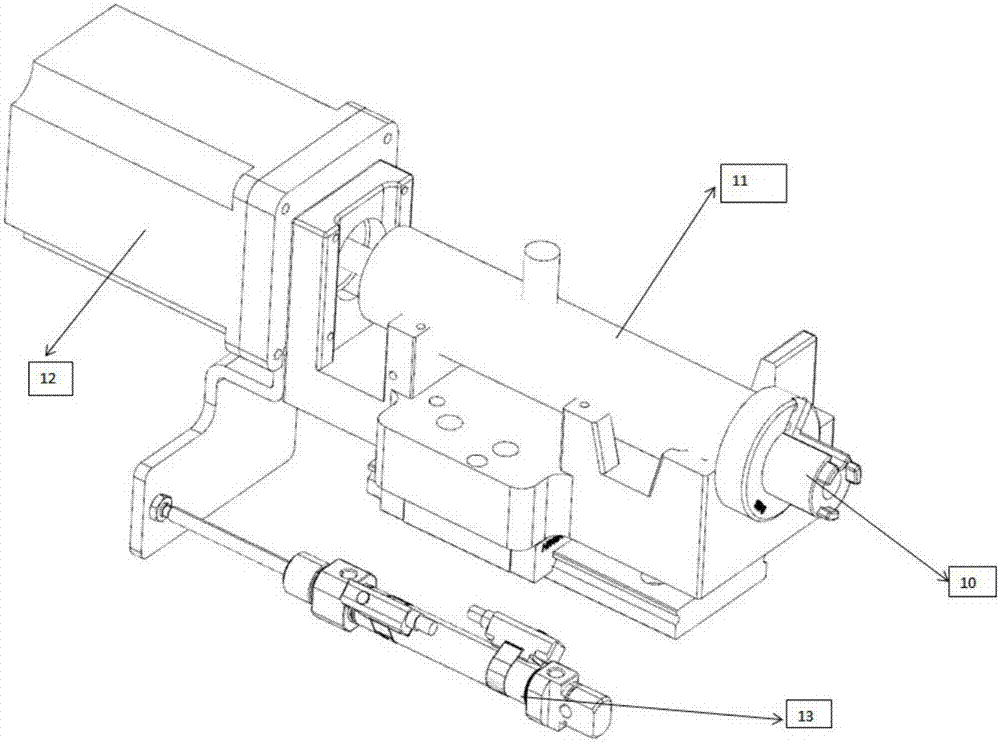

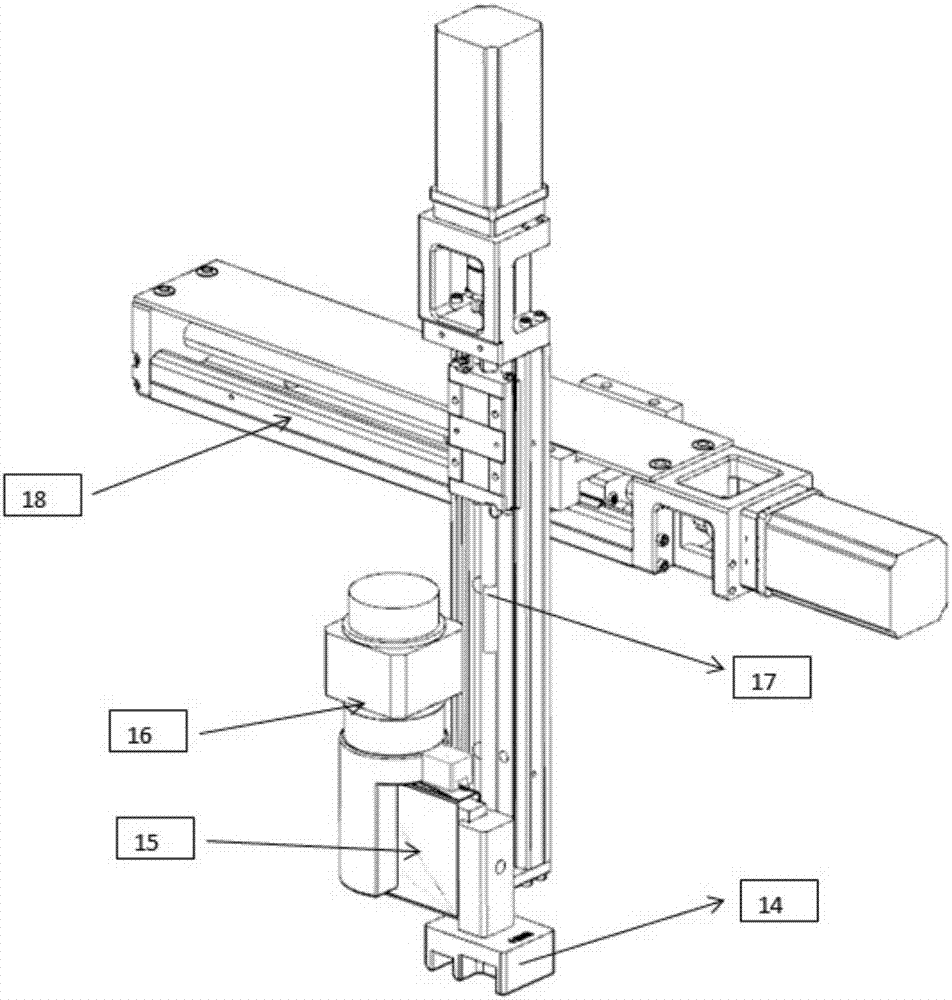

[0019] Such as Figure 1~4 As shown, a thumb wheel torque automatic force measuring device includes a housing, a PLC control box 20 and a printer 21 arranged on one side of the housing, a Y-axis guide rail 5 arranged at the inner bottom of the housing, and a Y-axis guide rail 5 arranged at the bottom of the housing. The mobile platform 6 on the mobile platform, the tooling base 7 and the clamping cylinder 9 respectively arranged on the mobile platform 6, the stroke force measuring device arranged above the clamping cylinder 9, and the Z-axis guide rail 17 connected with the stroke force measuring device, The X-axis guide rail 18 connected with the Z-axis guide rail 17 is provided with a thumb wheel force measuring device on the mobile platform 6 , and the PLC control box 20 is connected with the printer 21 . The stroke force measuring device includes a stroke force fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com