Green and high-efficiency rust inhibitor for reinforced concrete

A technology of reinforced concrete and rust inhibitor, which is applied in the field of green and high-efficiency reinforced concrete rust inhibitor, can solve problems such as corrosion of steel bars, and achieve the effects of inhibiting corrosion, increasing the area, and enhancing the corrosion inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

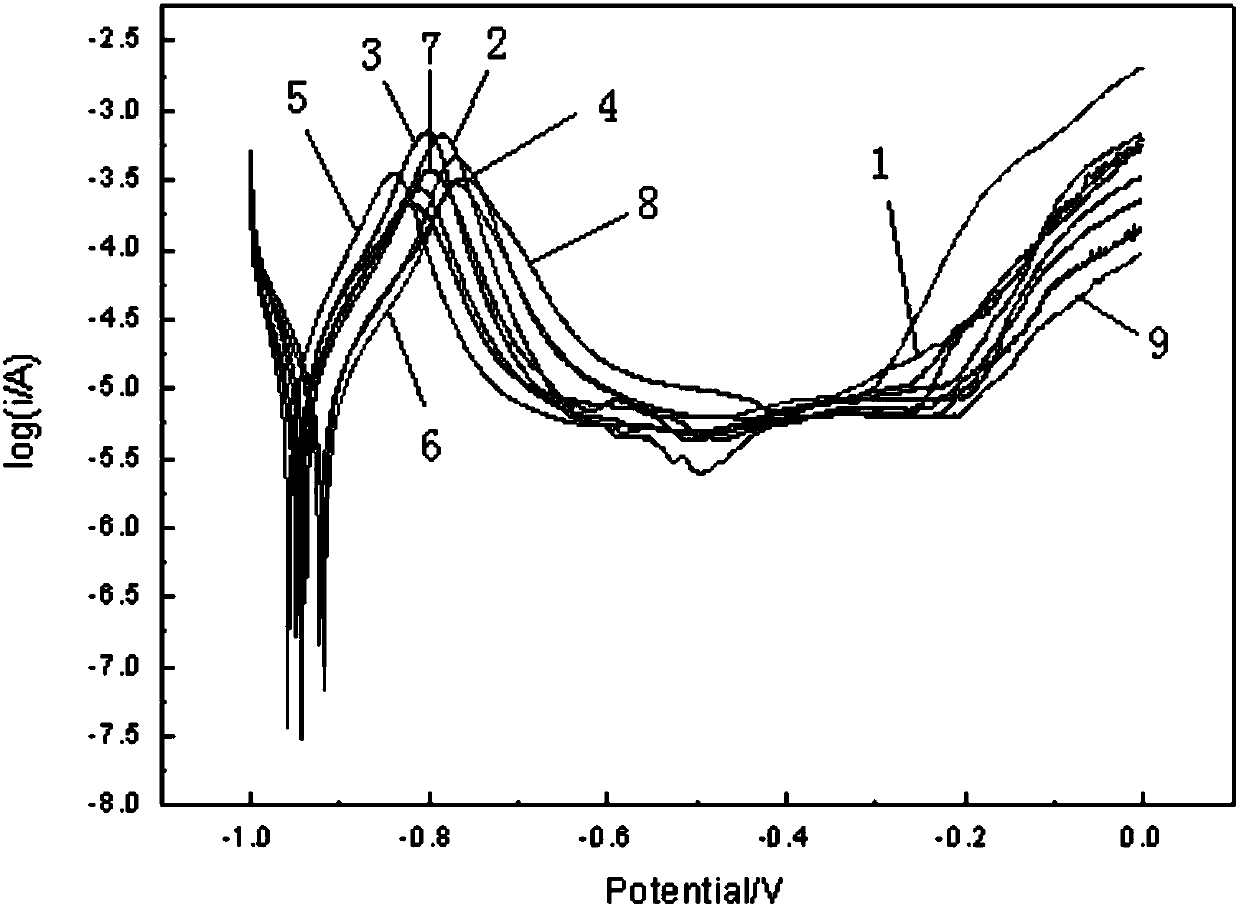

Image

Examples

Embodiment 1

[0050] Reinforced concrete rust inhibitor, each component is: 0.2g / L sodium molybdate, 1.0g / L thiourea, 5mL / L tetraethylenepentamine, 15mL / L phytic acid, and the rest is water. The reinforced concrete prepared by adding this rust inhibitor is kept in the air for 5 years without corrosion.

Embodiment 2

[0052] Reinforced concrete rust inhibitor consists of the following components: sodium molybdate 0.2g / L, thiourea 0.8g / L, tetraethylenepentamine 6mL / L, phytic acid 14mL / L, and the rest is water.

Embodiment 3

[0054] High-efficiency rust inhibitor for reinforced concrete, composed of the following components: sodium molybdate 0.15g / L, thiourea 0.8g / L, tetraethylenepentamine 6mL / L, phytic acid 17mL / L, and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com