A composite material acoustic detection sensor and detection method

A technology for detecting sensors and composite materials, used in scientific instruments, analytical materials, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as inability to obtain broadband vibration detection signals, unsatisfactory detection results, and difficult processing. , to achieve the effect of easy spectrum analysis, easy analysis and processing, and improved detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

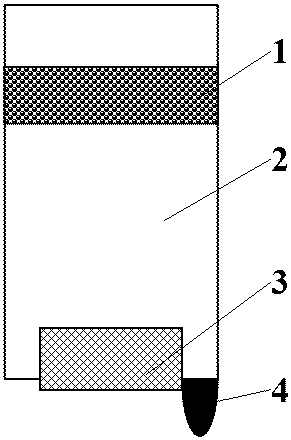

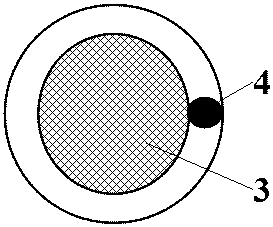

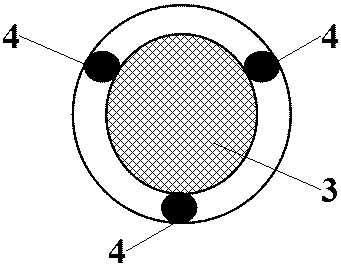

[0015] Examples such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a composite material acoustic detection sensor includes an excitation piezoelectric wafer 1, a vibrating rod 2, a capacitive microphone 3, and a contact 4, and is characterized in that: the excitation piezoelectric wafer 1 is fixed on the top surface of the vibrating rod 2 , the excitation piezoelectric wafer 1 is used to excite the vibrating rod 2, so that the vibrating rod 2 generates mechanical vibration; the capacitive microphone 3 is fixed on the bottom end surface of the vibrating rod 2, and the capacitive microphone 3 is used to receive the detected The composite material 5 detects the acoustic signal 6 generated by the forced vibration of the part; the contact 4 is fixed on the bottom end surface of the vibrating rod 2 and around the condenser microphone 3, and the contact 4 is used to transmit the mechanical vibration generated by the vibrating rod 2 To the inspected composite material 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com