Machining unit

A technology for processing units and workpieces, applied in metal processing, metal processing equipment, workpieces, etc., can solve the problems of high cost, prolong the takt time of processing workpieces, etc., and achieve the effect of long life and effective effect of multiple bristles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

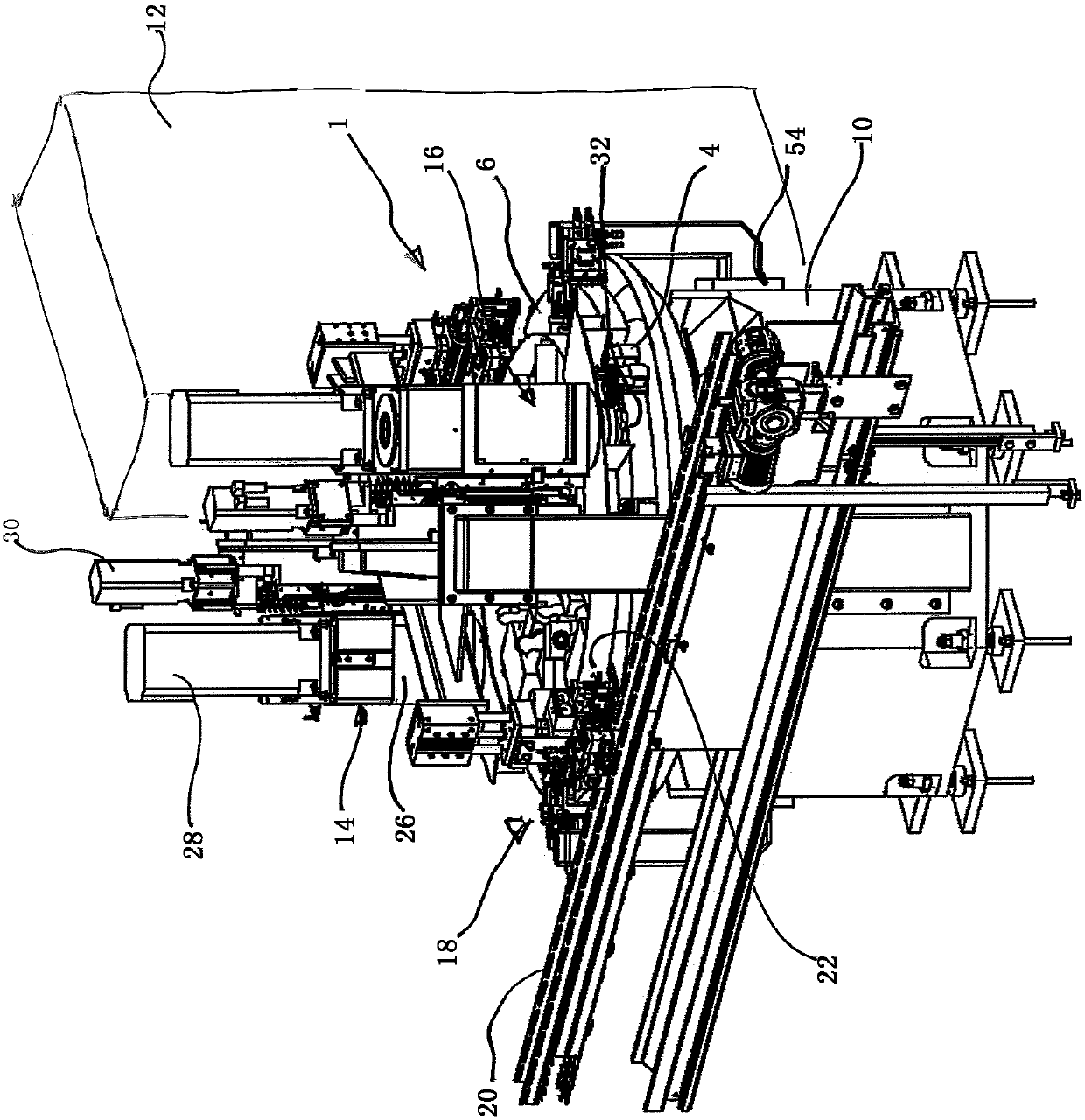

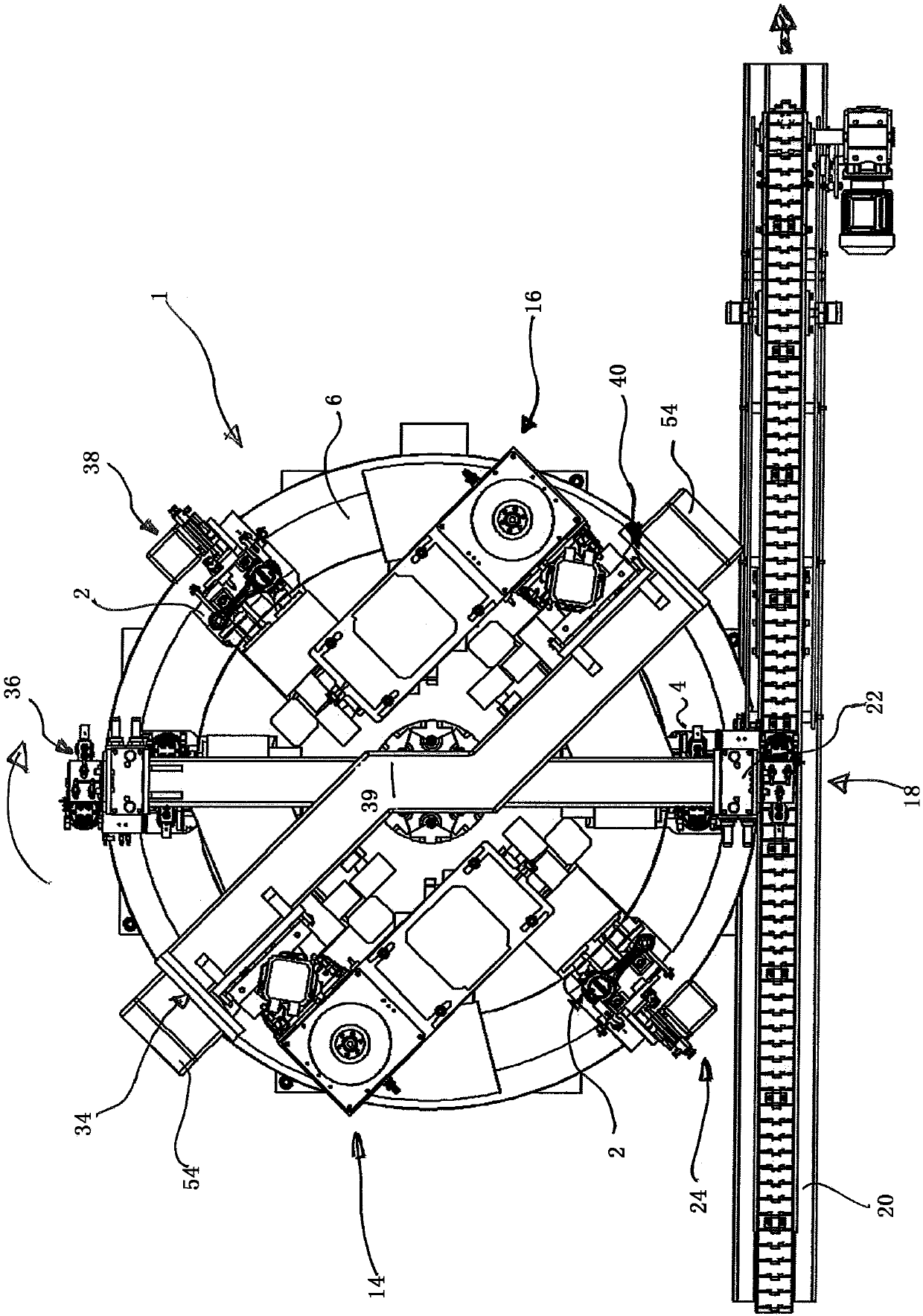

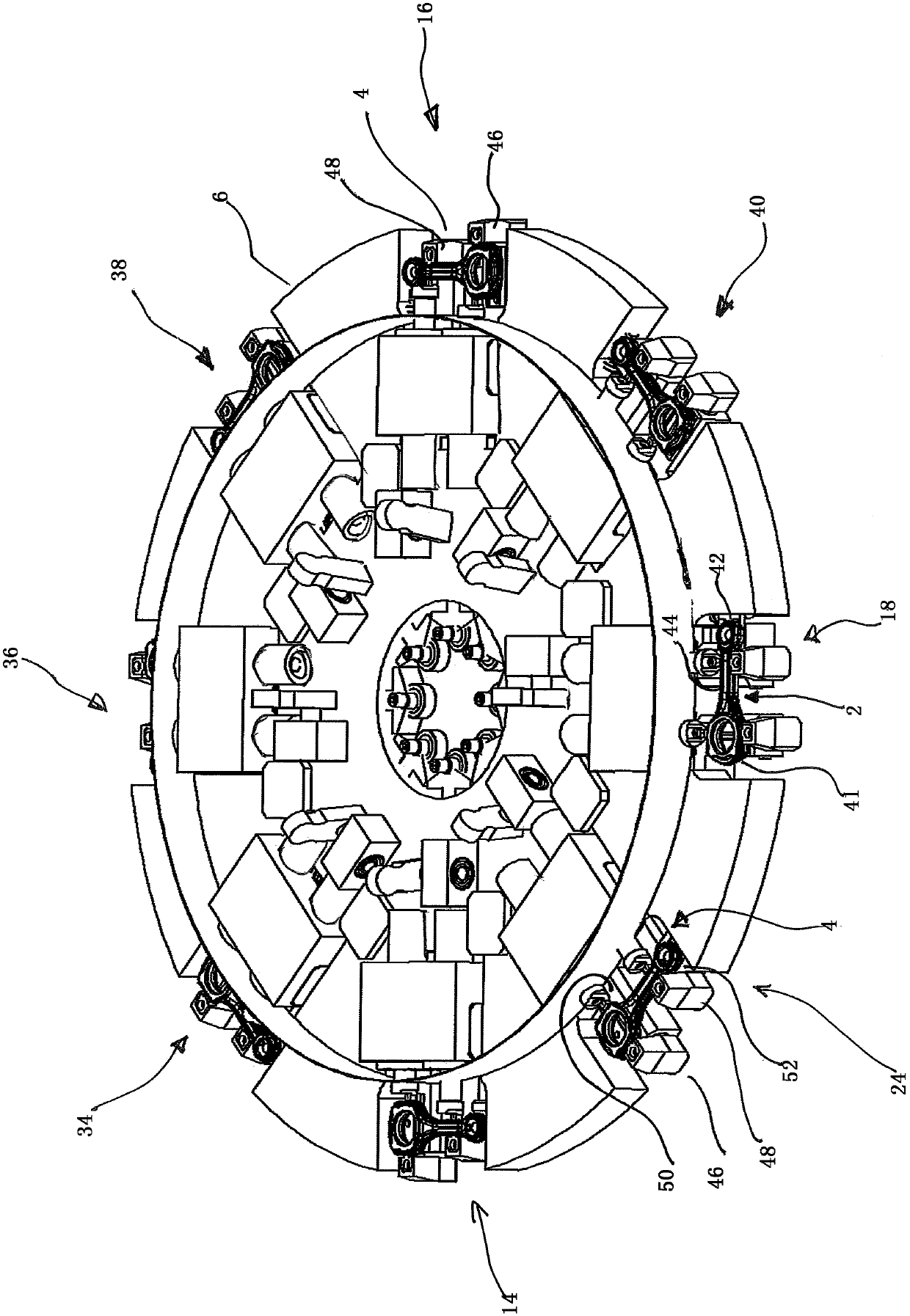

[0043] figure 1 Shown according to the present invention for the connecting rod (see figure 2 ) in a three-dimensional view of a first embodiment of a machining unit 1 for planar machining, the connecting rod is held on a rotatably supported NC circular table 6 by means of a clamping device also called a clamping nest. This NC circular table 6 is mounted rotatably on a frame 10 of the processing unit 1 and can be driven clockwise or cyclically via the machine control. In the exemplary embodiment shown, processing unit 1 has a total of eight processing stations, which will be explained in greater detail below. Two of the machining stations are designed as finishing stations 14 , 16 , at which the planes of the connecting rods are finished. The loading and unloading of the connecting rods is done via the loading and unloading workstation 18 . This loading and unloading station has a conveyor belt 20 via which the connecting rods to be processed are conveyed and discharged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com