Redundant switching control system of thyristor rectifying device under compensation operation in aluminum electrolytic cell

A control system and redundant switching technology, applied to the compensation structure in the electrolytic cell, the field of the redundant switching control system of the thyristor rectifier under the compensation operation in the electrolytic cell of the aluminum electrolysis industry, can solve the problem that the aluminum electrolytic cell cannot be produced normally, the aluminum liquid level Uplift, fluctuation and other problems, to achieve the effect of ensuring control synchronization, current balance, safe and reliable network communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

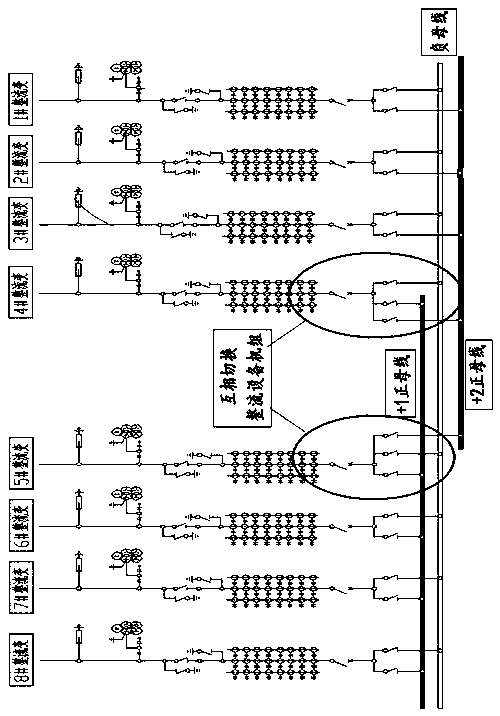

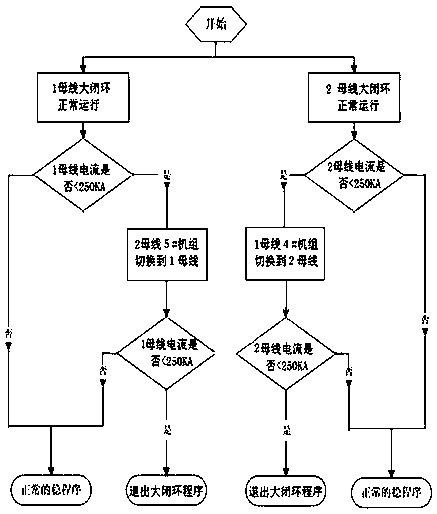

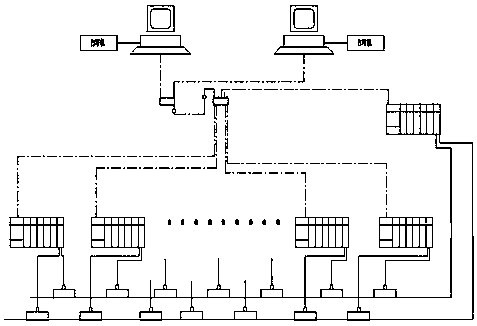

[0015] Such as Figure 1-3 As shown, the present invention works and implements in this way. The thyristor rectifier redundant switching control system under compensation operation in the electrolytic cell of the aluminum electrolysis industry mainly refers to two independent large closed-loop operation states of two busbars in the aluminum electrolysis industry. The thyristor rectifier device redundant switching control system is used. The rectifier device is composed of two sets of "3+1"+"3+1" combined mode parallel power supply and current stabilization systems. The two sets of "3+1" include 1# thyristor Rectifier unit, 2# thyristor rectifier unit, 3# thyristor rectifier unit and 4# thyristor rectifier unit, 6# thyristor rectifier unit, 7# thyristor rectifier unit, 8# thyristor rectifier unit and 5# thyristor rectifier unit; "3+1" + "3+1" combined mode Parallel power supply and current stabilization system controls 4 rectifier units, "3+1" + "3+1" combination mode Parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com