Application of Super Oil-absorbing Resin in Pesticide Preparation

A technology for super absorbent resin and pesticide formulations, applied in the field of pesticides, can solve the problems of seeds stuck in the holes of the planter, affecting sowing, difficult drying of the coated seeds, etc., and achieves the advantages of improving stability, inhibiting sedimentation and prolonging the duration of validity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

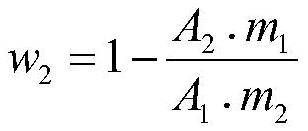

Method used

Image

Examples

Embodiment 1

[0044] Suspending agent (SC)

[0045] According to the formula requirements, absorb the active ingredients in the acrylate super oil-absorbing resin (PFSZ01), stir and mix evenly, mix the wetting dispersant, emulsifier, thickener, dispersion medium, etc., carry out high-shear pre-dispersion, and then add Grinding in a sand mill until the particle size is less than 5 μm, the suspending agent can be prepared.

[0046] 01#—04#: The same operation steps are propiconazole 10%, NNO 2%, YUS-TXC 3%, TX-10 1%, Tween80 2%, xanthan gum 0.04%,

[0047] The different process is 01# adding magnesium aluminum silicate 0.5%,

[0048] 02# add 0.5% of white carbon black,

[0049] 03#Add organic bentonite 0.5%,

[0050] 04# add montmorillonite 0.5%,

[0051] Finally, each was made up to 100% with water.

[0052] 05#: propiconazole 10%, put it in an oven at 50°C until it softens, add PFSZ01 1%, mix evenly by hand to absorb, add NNO 2%, YUS-TXC 3%, TX-10 1%, Tween 80 2 %, xanthan gum 0.04%, ...

Embodiment 2

[0067] Suspoemulsion (SE)

[0068] According to the formula requirements, absorb the active ingredients in the acrylate super oil-absorbing resin (PFSZ01), stir and mix evenly, mix the wetting dispersant, emulsifier, thickener, dispersion medium, etc., carry out high-shear pre-dispersion, and then add Grinding in a sand mill until the particle size is less than 5 μm, the suspension seed coating can be prepared.

[0069] 01#-04#: The same operation steps are propiconazole 10%, thiram 5%, AEO-33%, YUS-FS30003%, TX-10 1%, Nongru 0201B 2%, xanthan gum 0.06%,

[0070] The different process is 01# adding 0.8% magnesium aluminum silicate,

[0071] 02# add 0.8% of white carbon black,

[0072] 03# add organic bentonite 0.8%,

[0073] 04# add montmorillonite 0.8%,

[0074] Finally, each was made up to 100% with water.

[0075] 05#: Propiconazole 10%, put in an oven at 50°C until it softens, add PFSZ01 7%, mix evenly and stir for adsorption, thiram 5%, AEO-3 3%, YUS-FS3000 3%, TX-10...

Embodiment 3

[0080] Dispersible oil suspension (OD)

[0081] According to the formula requirements, the active ingredients are adsorbed in the acrylate super oil-absorbing resin (PFSZ01), stirred and mixed evenly, and the wetting and dispersing agent, emulsifier, thickener, non-aqueous dispersion medium, etc. are mixed, and high-shear pre-dispersion is carried out. Then put it into a sand mill, and grind until the particle size is less than 5 μm, so that the oil suspension can be prepared.

[0082] 01#-04#: The same operation steps are 10% of enoxastrobin, 10% of tebuconazole, 2% of dispersant A, 1% of AEO-3, 3% of Nongru 600#,

[0083] The different process is 01# adding magnesium aluminum silicate 2%,

[0084] 02# add 2% white carbon black,

[0085] 03# add organic bentonite 2%,

[0086] 04# add montmorillonite 2%,

[0087] Finally, methyl oleate was used to make up to 100%.

[0088] 05#: Enoxastrobin 10%, Tebuconazole 10%, Dispersant A 2%, AEO-3 1%, Nongru 600# 3%, add PFSZ01 10%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com