Plug-in miniature circuit breaker

A small circuit breaker, plug-in technology, applied in the direction of circuits, parts of protective switches, electrical components, etc., can solve the problems of inconvenient disassembly and replacement, long power-off time, easy to shift or fall off, etc., to achieve Effects of shortened power-off time, easy replacement, and improved structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

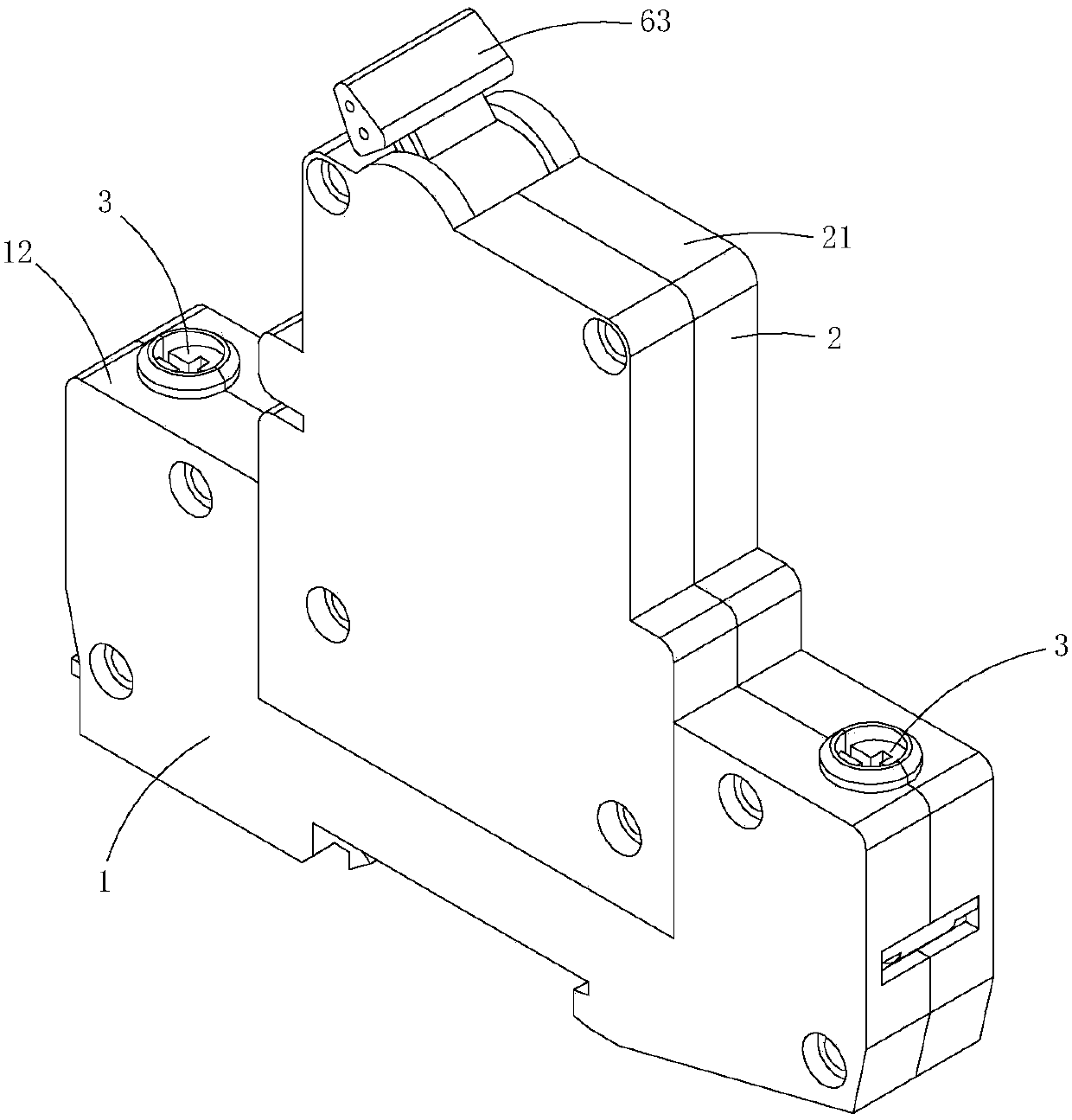

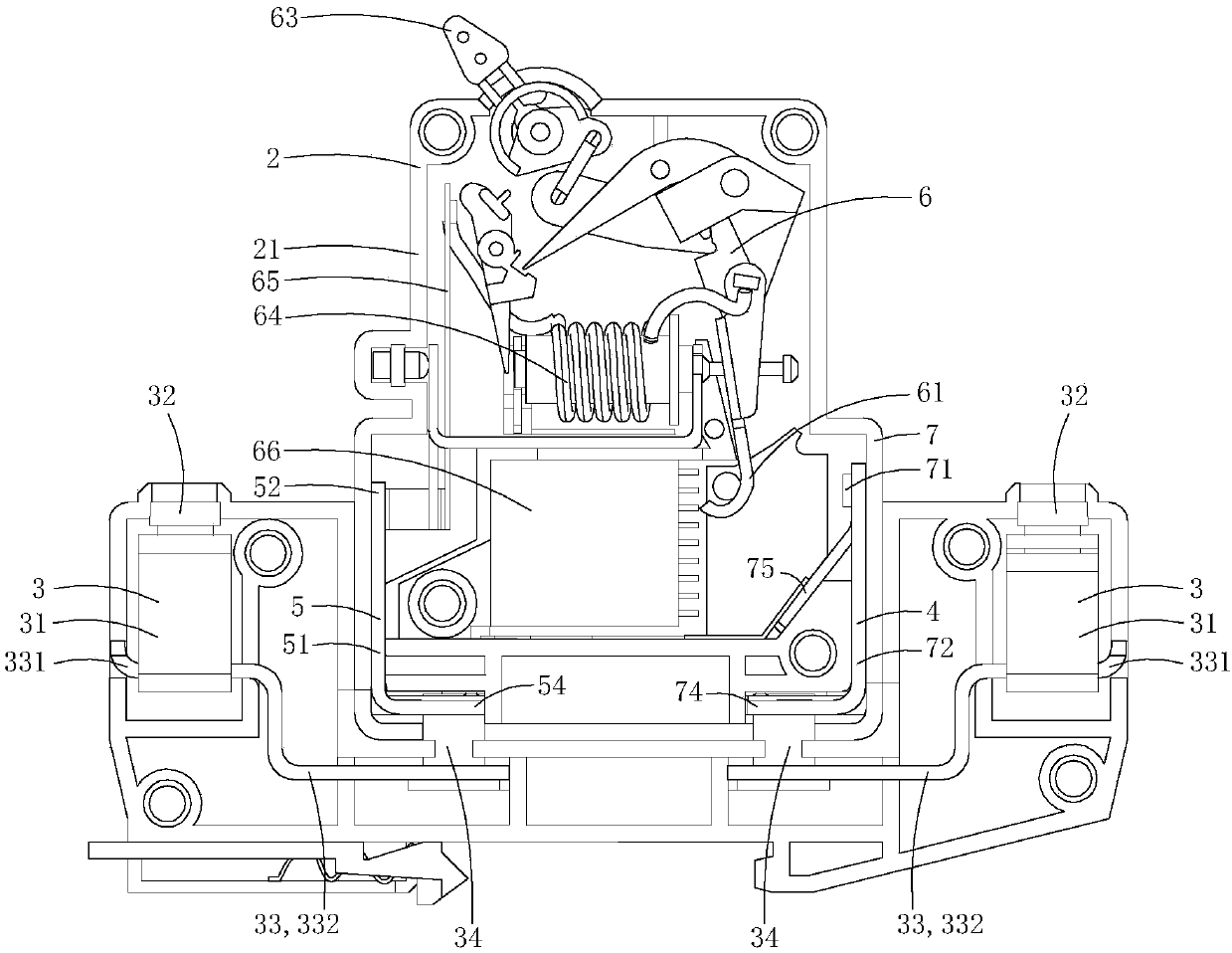

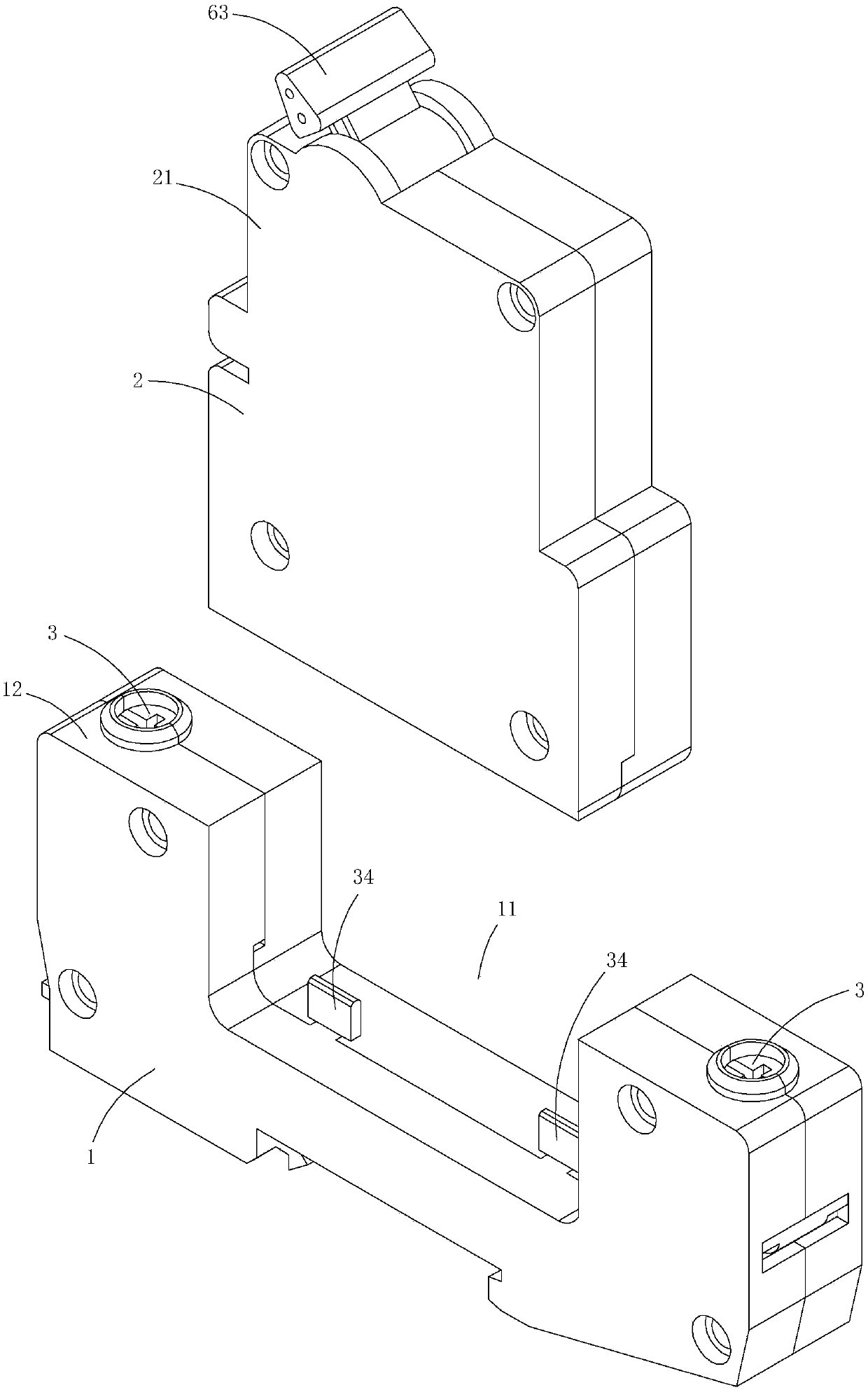

[0021] This embodiment is a plug-in miniature circuit breaker, see Figure 1 to Figure 11 As shown, it includes base 1 and plug-in circuit breaker module 2.

[0022] The base 1 includes a base housing 12 provided with a socket 11 and two terminal assemblies 3, and the pluggable circuit breaker module is pluggably installed in the socket.

[0023] See Figure 5 with Image 6 As shown, each terminal assembly 3 includes a metal frame 31, a terminal screw 32, an electrical terminal 33 and an electrical plug-in board 34; the metal frame is made of a steel plate into a rectangle, and the top of the metal frame is provided with a screw hole adapted to the terminal screw The electric terminal includes a clamping plate portion 331 and an electric plate portion 332; the electric terminal is embedded and fixed on the inner wall of the base shell of the electric seat, and the metal frame is movably arranged in the base shell; the electric terminal The clamping plate part passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com