Four-axis drive knife scissor grinding machine

A knives and scissors grinding machine, four-axis drive technology, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of low smoothness, rough surface of the knife surface, lack of reach, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A four-axis driven knife-scissor grinder of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

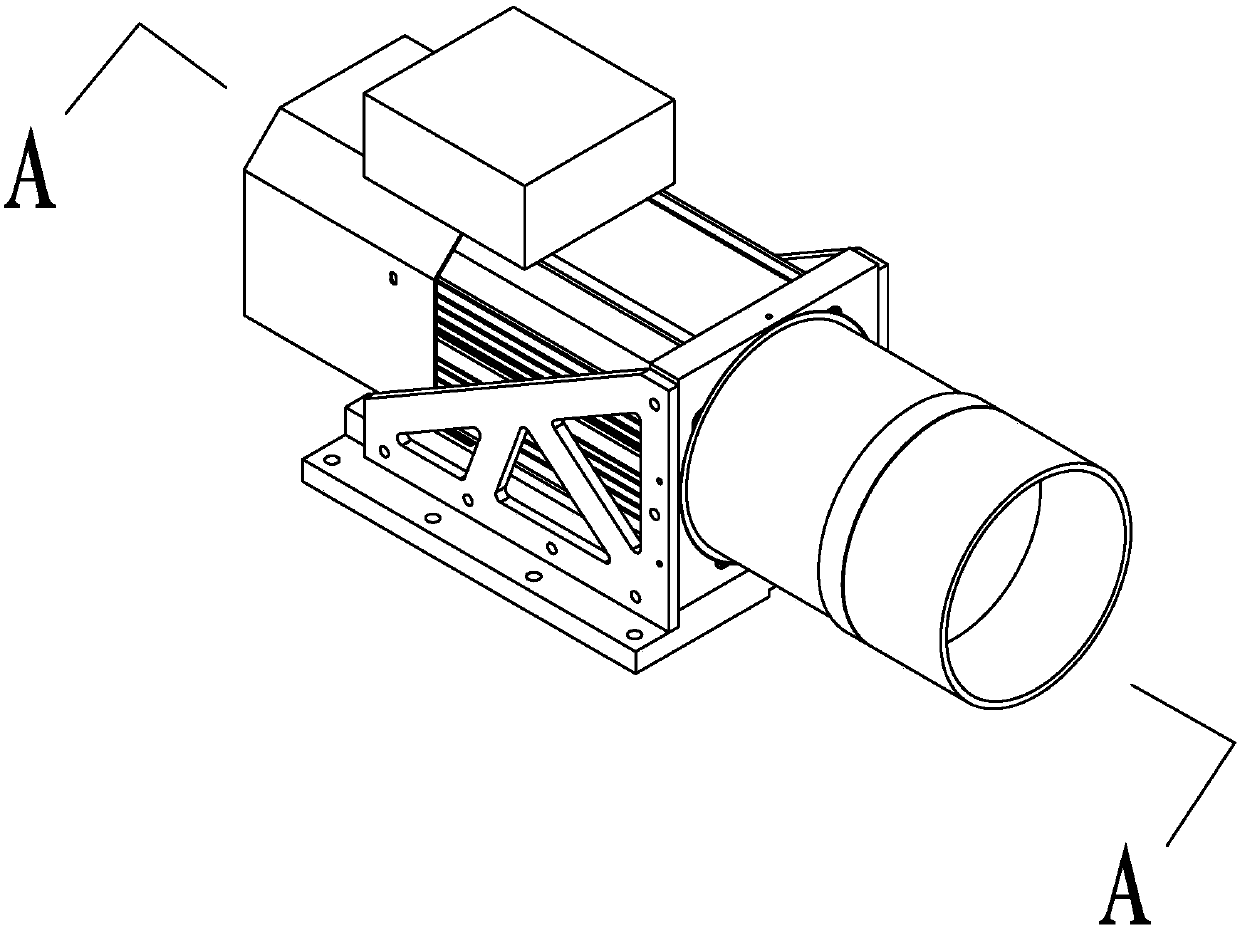

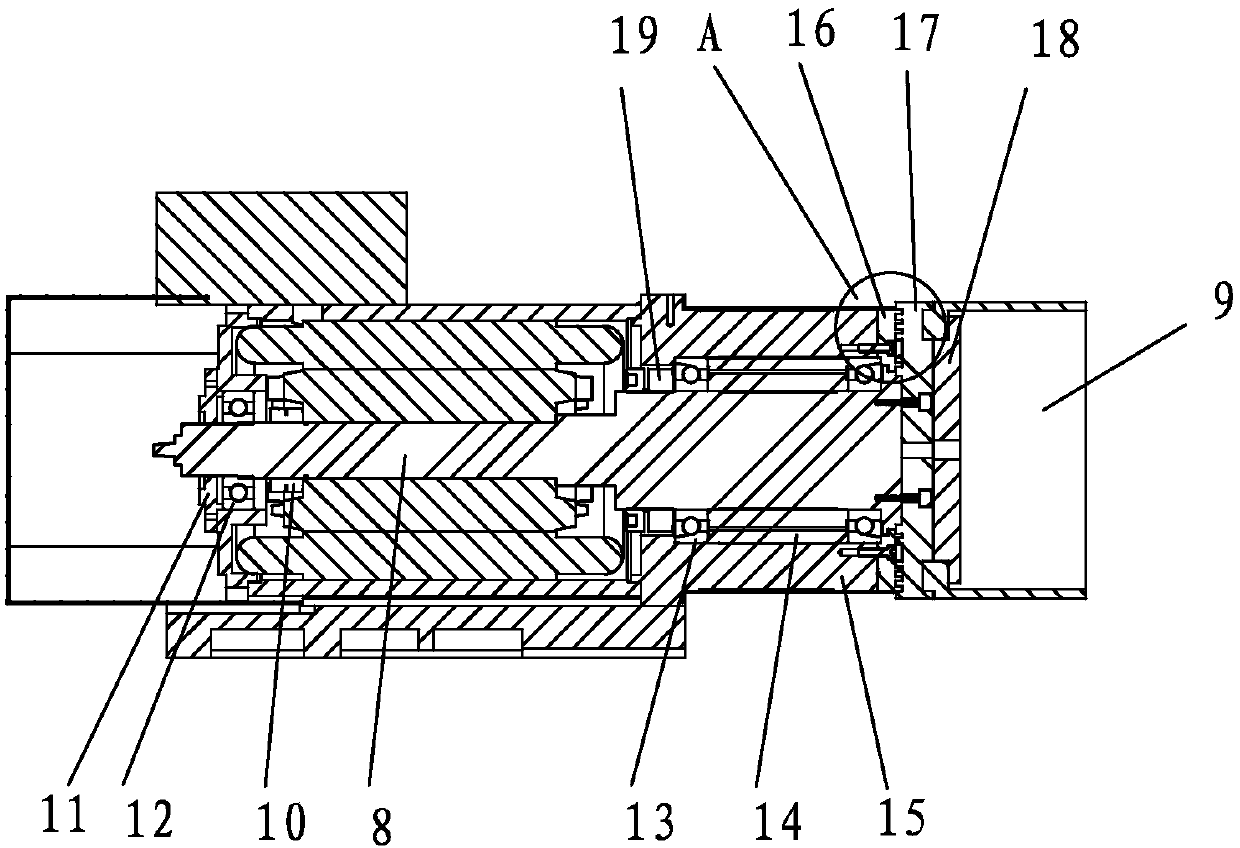

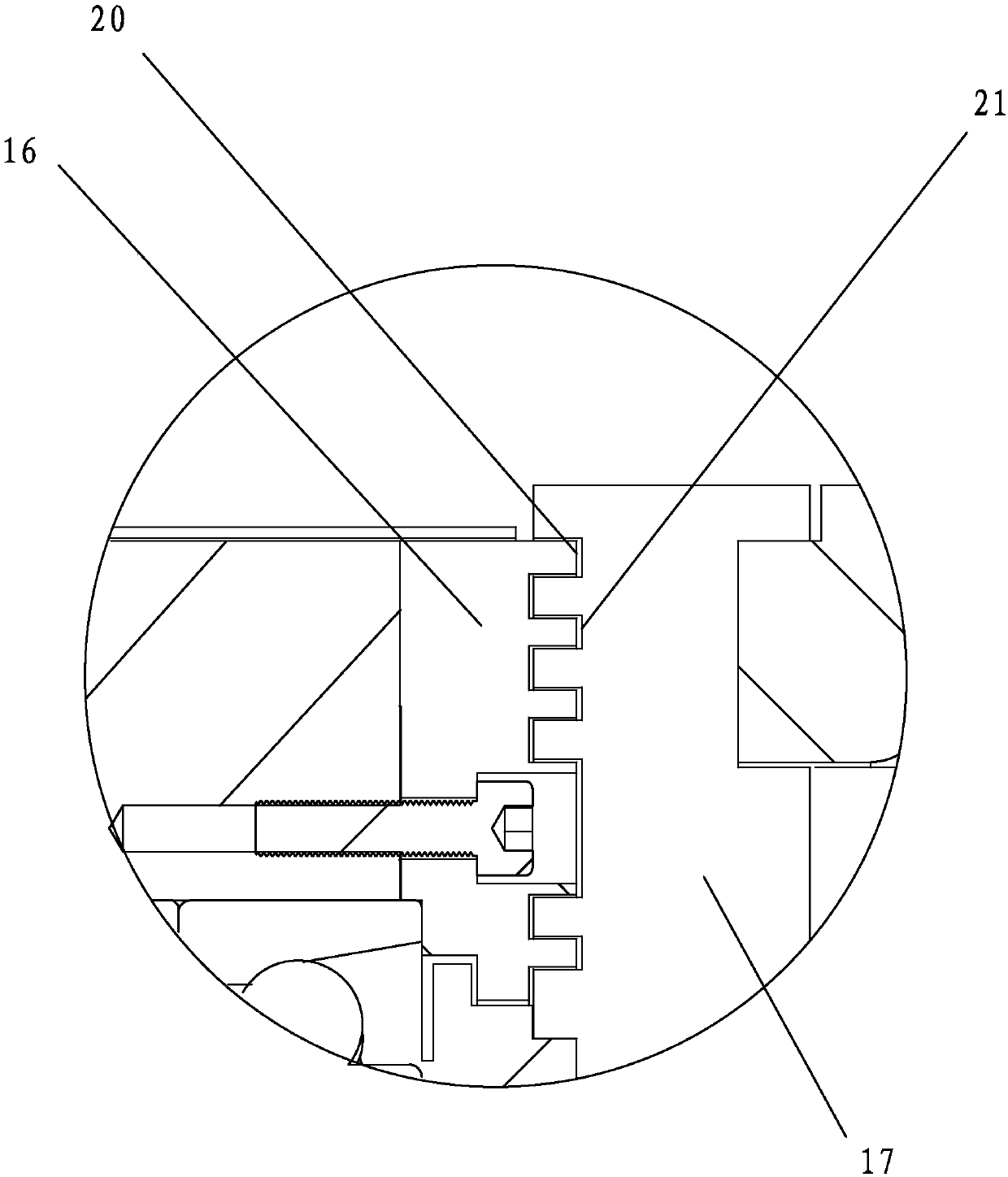

[0024] refer to Figure 1-Figure 8 , a kind of four-axis driven knife and scissors grinding machine designed by the present invention includes a mounting base 1, and a spindle guide rail device and a worktable guide rail device installed on the mounting base 1 at 90 degrees to each other and arranged horizontally. The main shaft assembly 2 and the workbench assembly 3 are respectively installed on the table guide rail device. A driving device and a power device are arranged under the main shaft assembly 2 and the worktable assembly 3 respectively, and the driving device and the power device respectively control the lateral movement and the longitudinal movement of the main shaft assembly 2 and the worktable assembly 3 . The main shaft assembly 2 includes a main shaft motor and a main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com