Z type ejector core pulling mechanism

A technology of core-pulling mechanism and ejector pin, which is applied in the field of injection molds for plastic parts, and can solve problems affecting the appearance quality of products, affecting the optical effect of light guides, and affecting the service life of core-pulling molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

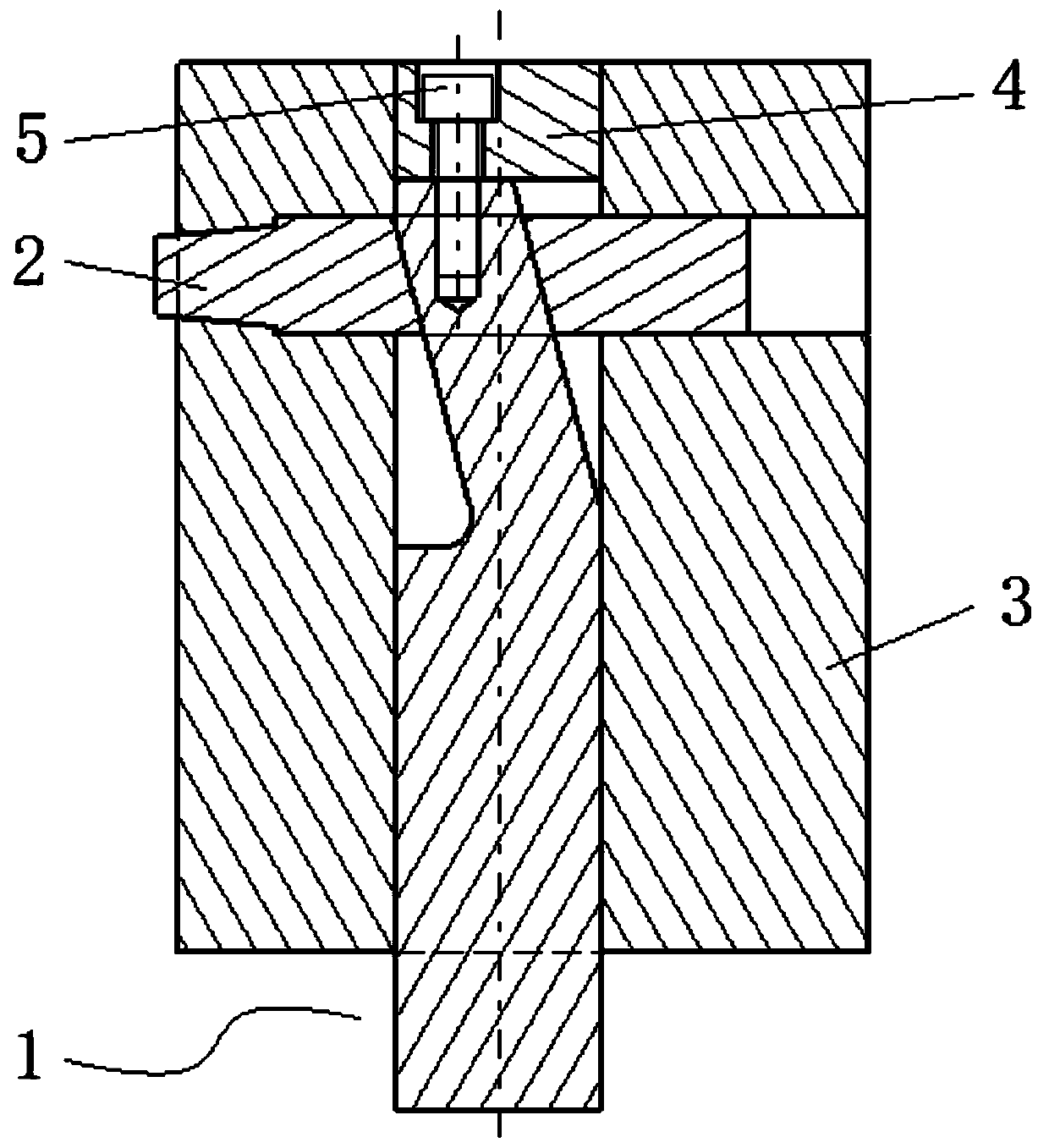

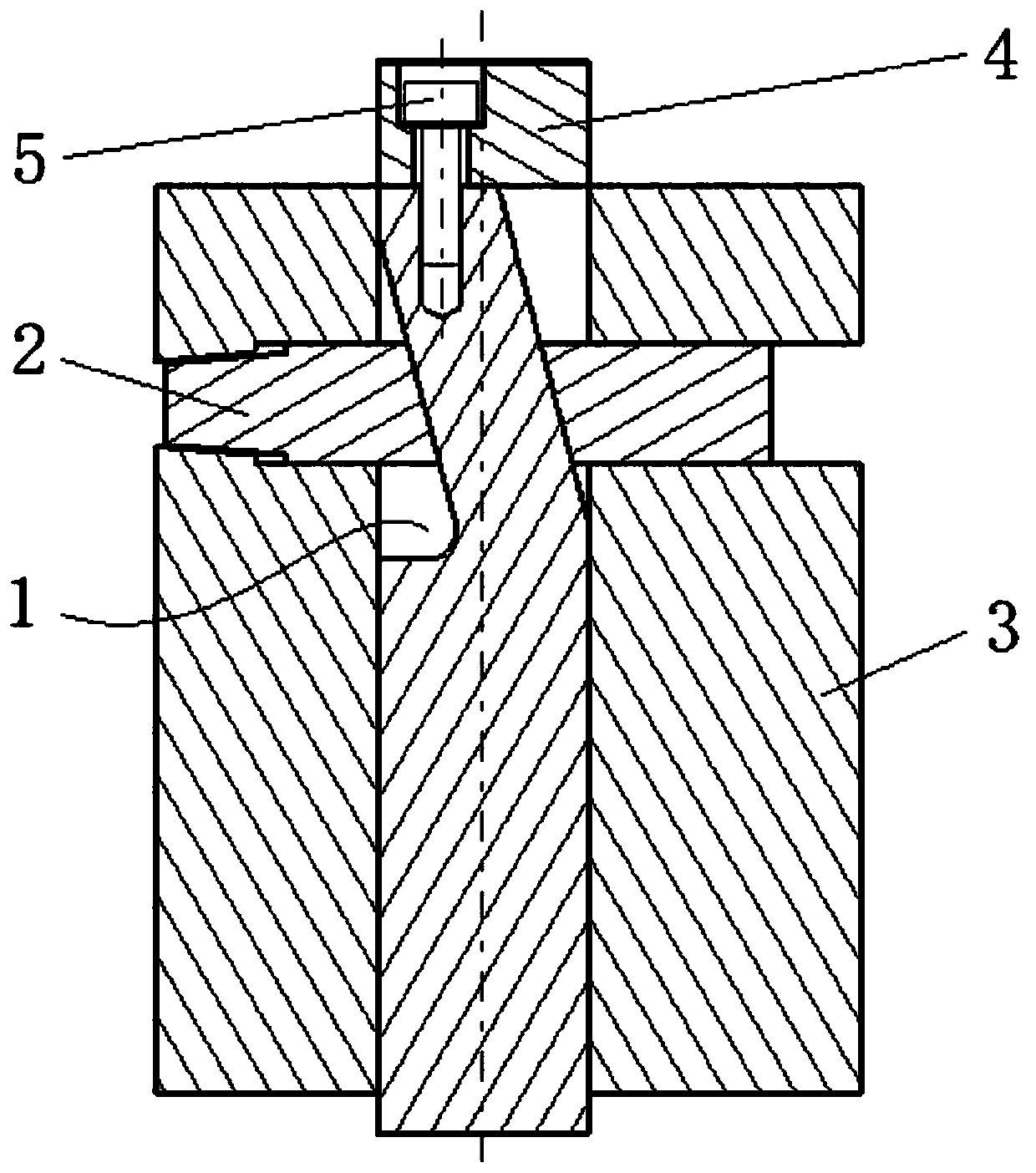

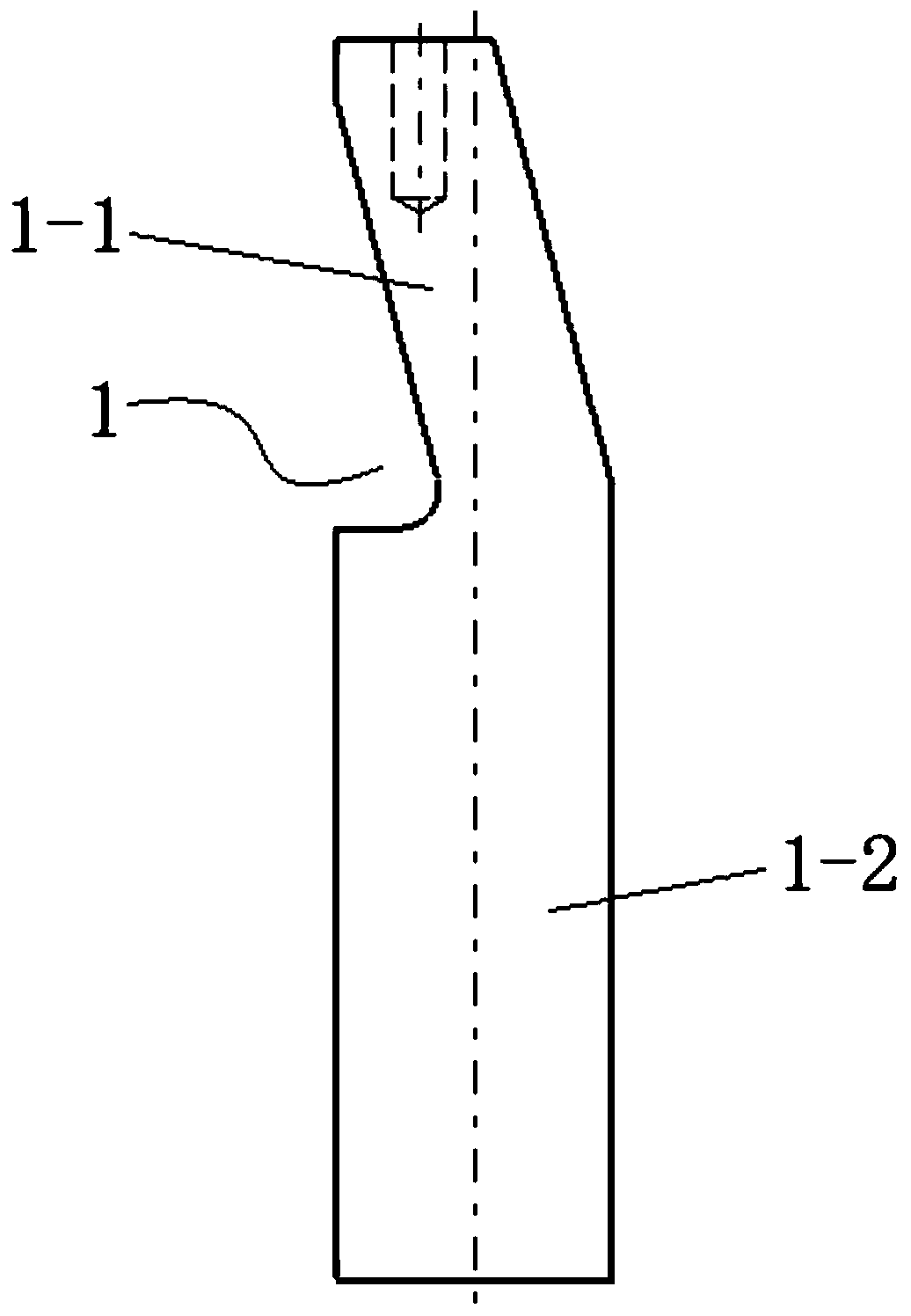

[0024] The invention discloses a Z-shaped ejector core-pulling mechanism, such as figure 1 As shown, the ejector rod 1 and the slide block 2 are included, and the ejector rod is vertically installed in a ejector rod installation hole of a base part 3 . The push rod is divided into upper and lower parts, namely a neck 1-1 and a body 1-2, and the push rod slides up and down with the base part through the body. The cross-sectional area of the neck is smaller than that of the body, and the neck is arranged at an inclination of upper left and lower right (or lower left and upper right). The projection of the neck on the horizontal plane does not exceed the body. The slider extends left and right and is installed in the chute of the base component, and slides and cooperates with the base component left and right, and the chute is a left and right through groove. The slider is conformably fitted on the neck through the oblique hole 2-1 in the middle, and is slidably engaged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com