LED optical engine module

A light engine and LED light board technology, applied in the field of lighting, can solve problems such as difficult LED heat dissipation, uncompact structure, unfavorable radiator heat dissipation, etc., and achieve the effect of convenient installation of LED light boards and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

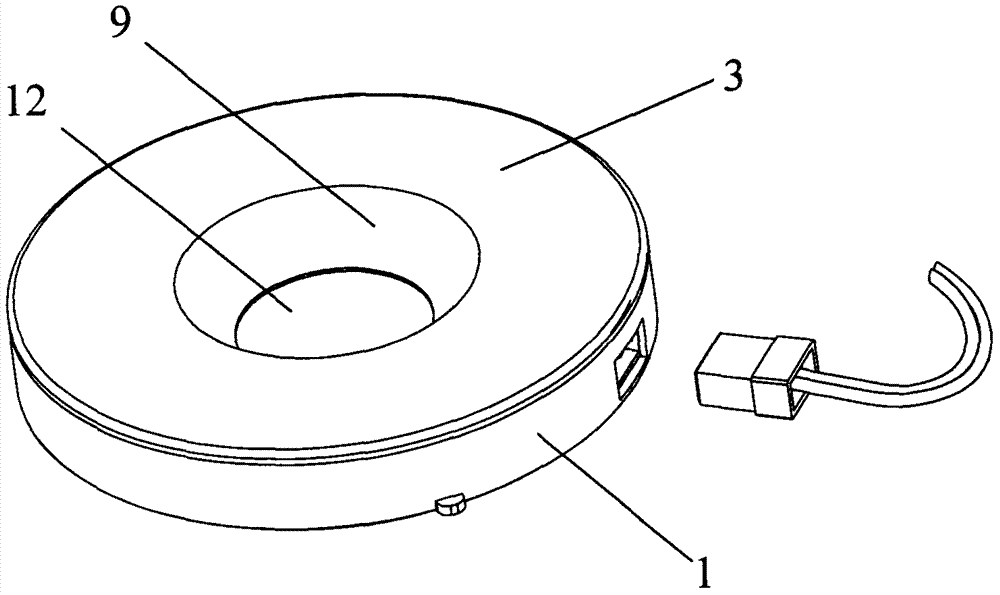

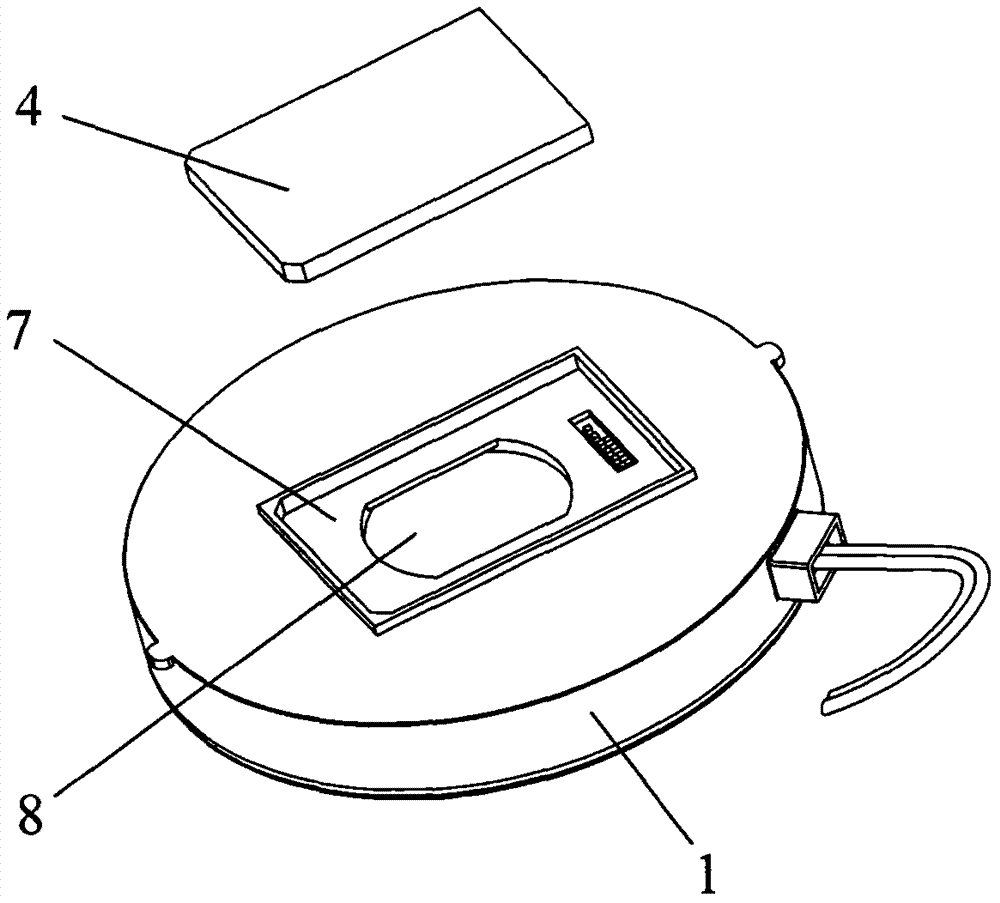

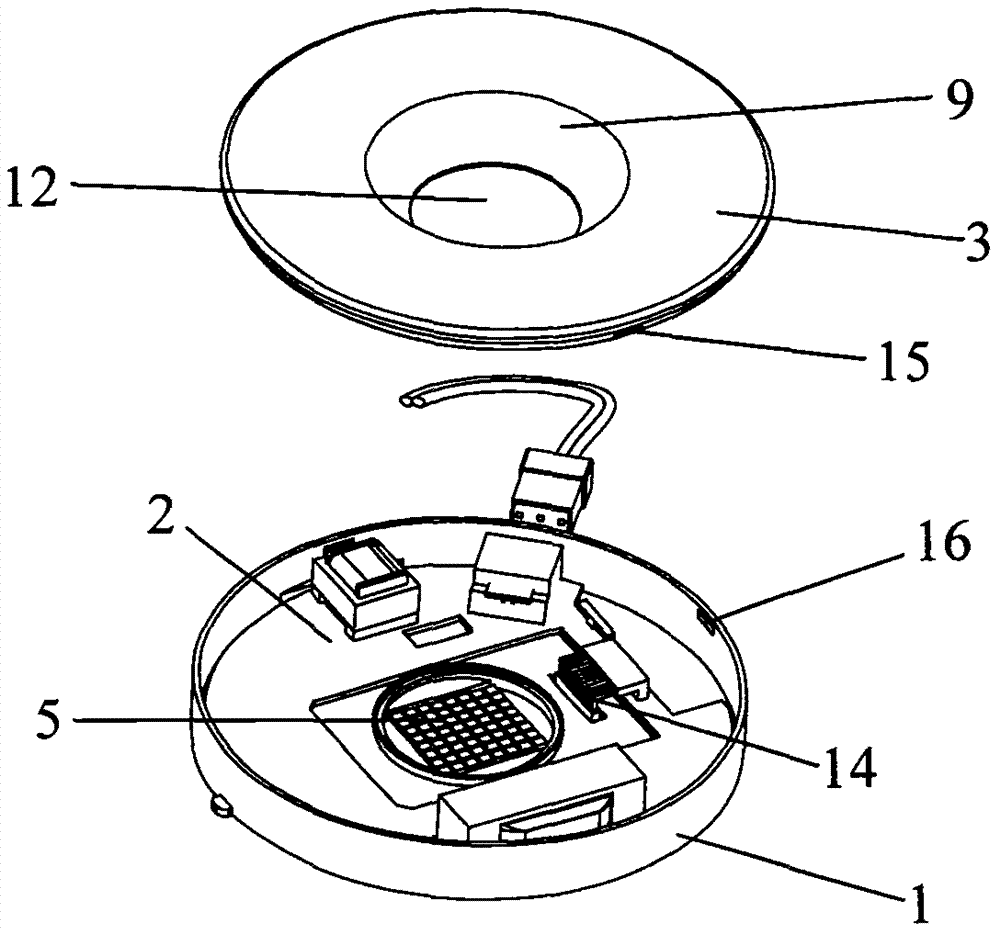

[0024] refer to figure 1 Referring to the preferred embodiment of the present invention shown in FIG. 5 , an LED light engine module includes a box body 1, a power supply module 2 disposed in the box body 1, a box cover 3 that covers the box body 1, and an LED light engine module. The lamp board 4, the LED lamp board 4 is a plurality of SMD LEDs 5 welded on the circuit substrate 6, the bottom of the box body 1 is provided with a concave cavity 7 that is concave from the bottom of the box body 1 to the inside of the box body 1, and the concave cavity The middle part of 7 is provided with a through hole 8 through the box body 1, the circuit substrate 6 of the LED lamp board 4 is set in the concave cavity 7 at the bottom of the box body 1, and the LED5 of the LED lamp board 4 is accommodated in the through hole 8 of the box body 1 , wherein the coverage of the through hole 8 is smaller than the coverage of the concave cavity 7, so that the circuit substrate 6 of the LED lamp boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com