Method for preparing active carbon from biomass, and prepared active carbon

A technology for preparing activated carbon and biomass, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of activated carbon product specific surface area to be improved, methods to be improved, etc., to achieve rich pore structure, reduce cost, and reduce environmental pollution pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing activated carbon from biomass, characterized in that the steps are as follows:

[0026] Step 1. Select waste paper scraps and dry them at 100°C for 6 hours to remove moisture, then crush them and pass them through an 80-mesh sieve for use;

[0027] Step 2, taking the pulverized biomass and placing it in a zinc chloride solution with a mass fraction of 65% and stirring rapidly for 1 minute to obtain a transparent gel-like intermediate product. The stirring speed is 350r / min, and the stirring time is 1min. The reaction in the second step is the chelation of the activator, which requires rapid stirring to realize the rapid formation of the gelatinous intermediate product and the uniform texture. The dosage ratio of the zinc chloride solution to the crushed biomass is to add 1g of the crushed biomass to every 3ml of the zinc chloride solution.

[0028] Step 3. Put the transparent gel-like intermediate product in a tube furnace under nitrogen protect...

Embodiment 2

[0032] A method for preparing activated carbon from biomass, characterized in that the steps are as follows:

[0033] Step 1. Select cotton and dry it at 100°C for 6 hours to remove moisture, then crush it and pass it through an 80-mesh sieve for use;

[0034] Step 2, taking the pulverized biomass and placing it in a zinc chloride solution with a mass fraction of 80% and stirring rapidly for 5 minutes to obtain a transparent gel-like intermediate product. The stirring speed is 400r / min, and the stirring time is 5min. The reaction in the second step is the chelation of the activator, which requires rapid stirring to realize the rapid formation of the gelatinous intermediate product and the uniform texture. The dosage ratio of the zinc chloride solution to the crushed biomass is to add 1g of the crushed biomass to every 3ml of the zinc chloride solution.

[0035] Step 3. Put the transparent gel-like intermediate product in a tube furnace under nitrogen protection, and perform ...

Embodiment 3

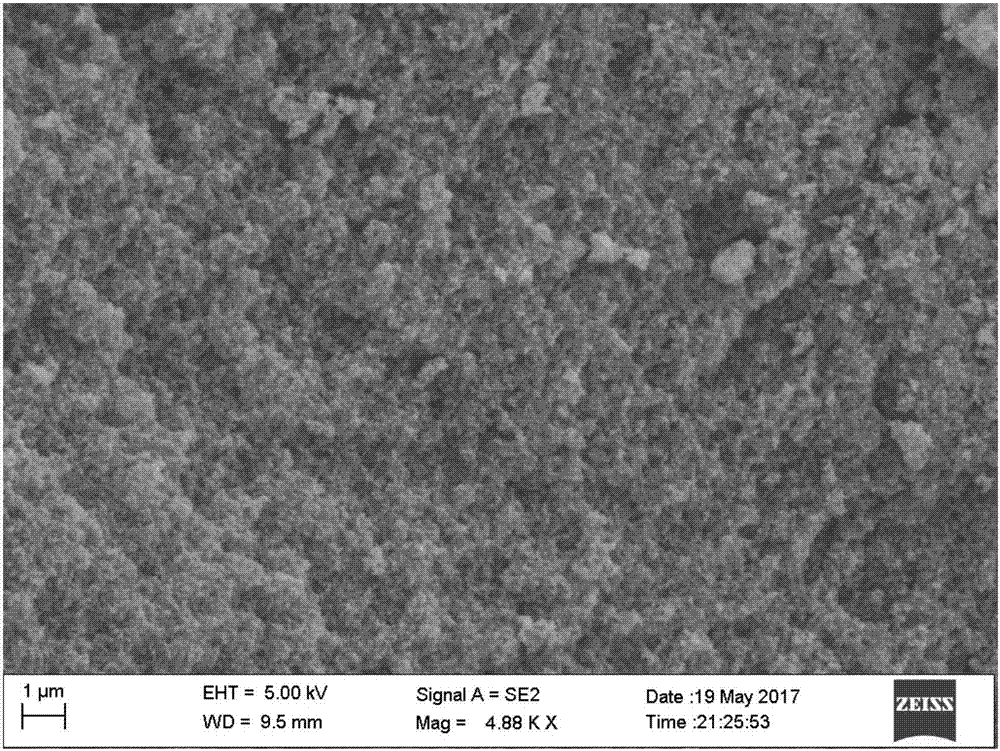

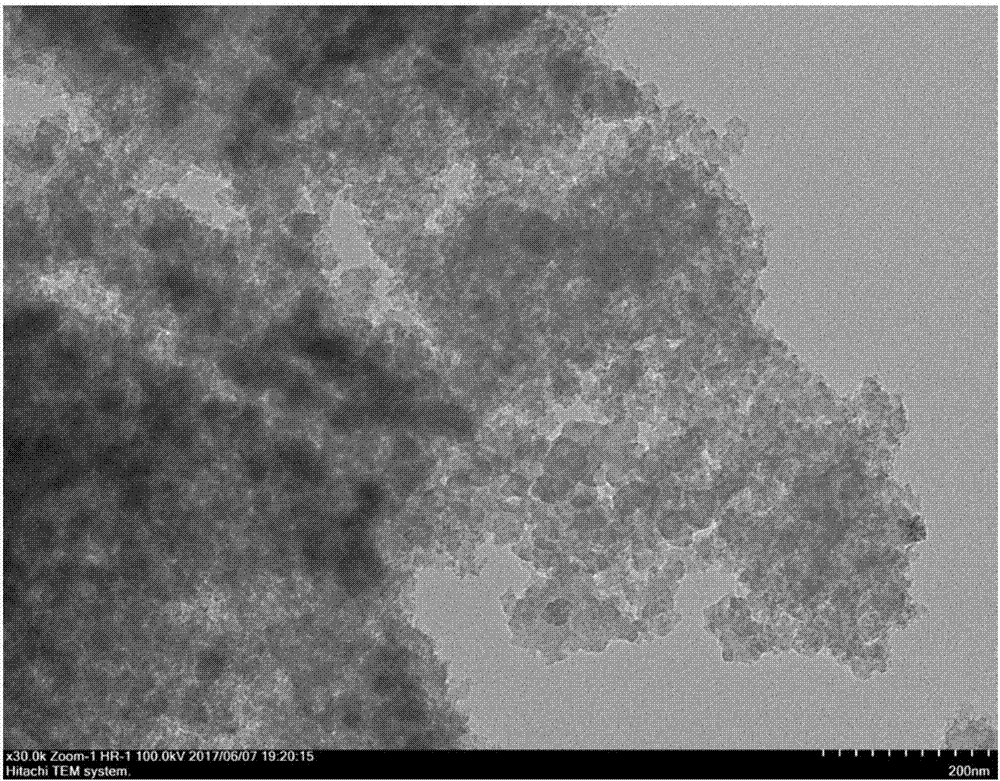

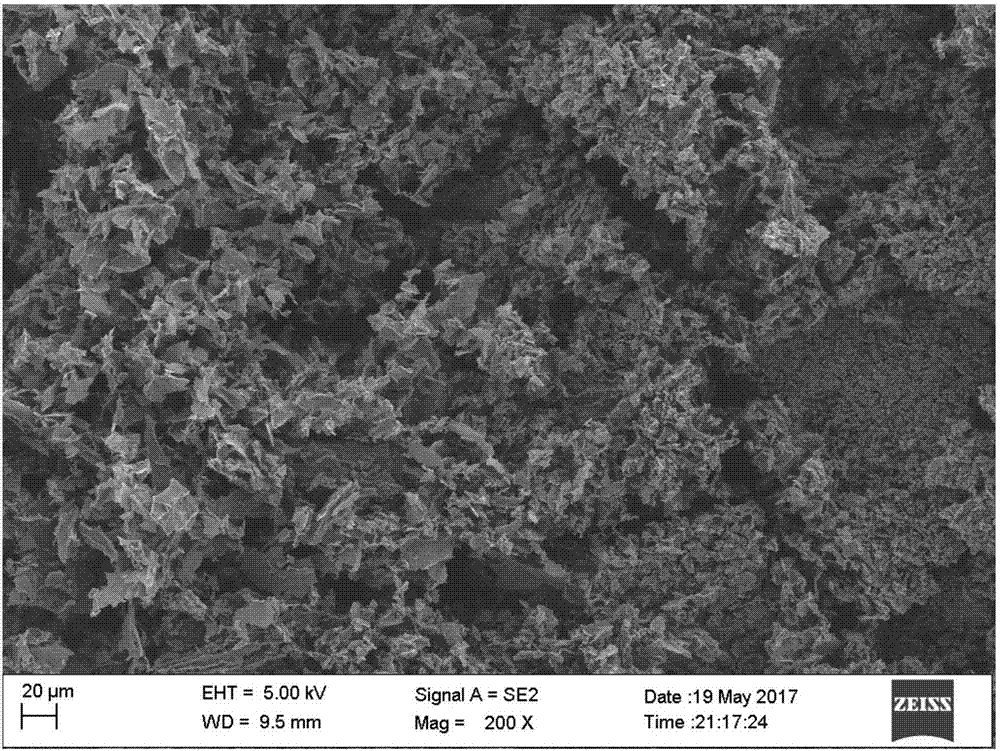

[0038]A method for preparing activated carbon by using biomass as a raw material, taking paper scraps and drying them in an oven at 100°C for 6 hours to remove moisture, and then crushing them through an 80-mesh sieve for use. Take 4g of pulverized paper scraps and place them in a 100ml beaker, add 12ml of zinc chloride solution with a mass fraction of 70%, and stir rapidly at a stirring speed of 400r / min for 2min to obtain a transparent gel intermediate product. The above-mentioned transparent gel intermediate product is placed in a porcelain boat and placed in the middle of a tube furnace for pyrolysis under the protection of nitrogen, and the gas outlet of the tube furnace is connected to a zinc chloride treatment and recovery device. The heating rate of the tube furnace is 5°C / min, the temperature is raised to 800°C, the heat treatment is 3h, and the flow rate of nitrogen gas is 30mL / min. The sample in the tube furnace was pickled with dilute hydrochloric acid with a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com