A kind of isothermal double-effect concentrating unit and concentrating method thereof

A double-effect concentration and concentration unit technology, which is applied in separation methods, chemical instruments and methods, multi-effect evaporation, etc., can solve problems such as unsuitable falling film concentration, fouling, and inapplicability to small batch production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

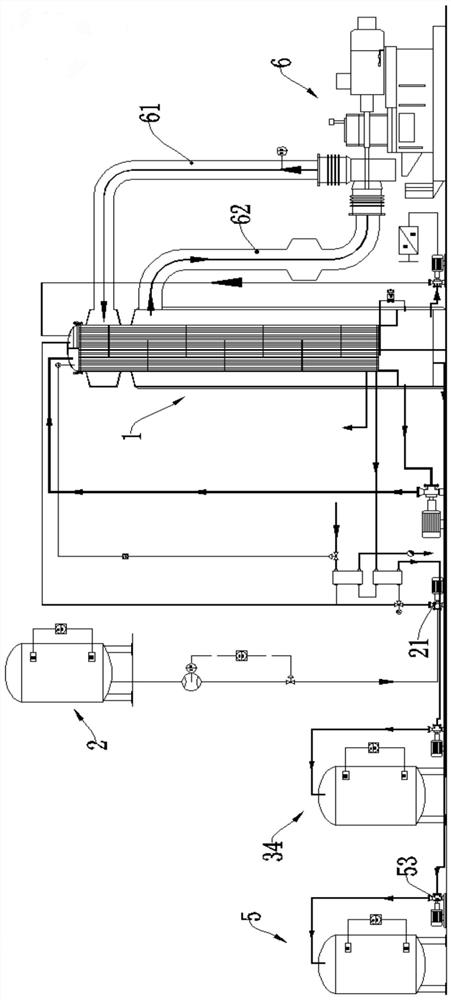

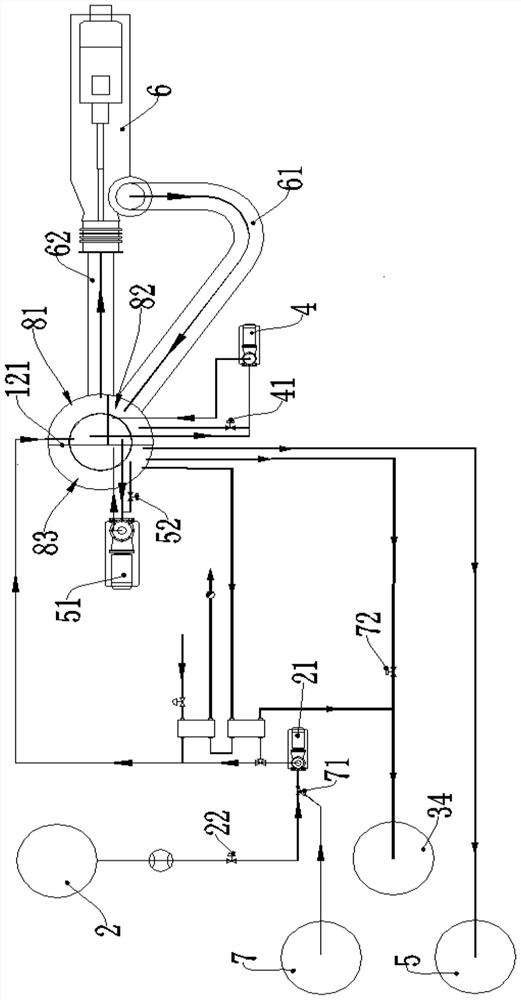

[0057] The isothermal double-effect concentrating unit of the present embodiment, such as figure 1 , image 3 As shown in the figure, it includes a double-effect concentration system and a secondary vapor recompression system, the double-effect concentration system is connected with the secondary vapor recompression system, and the double-effect concentration system sequentially includes a raw material tank 2, a preheating unit from upstream to downstream , the isothermal concentration tower body 13, the same body double effect heater 1 and the ointment collecting tank 5;

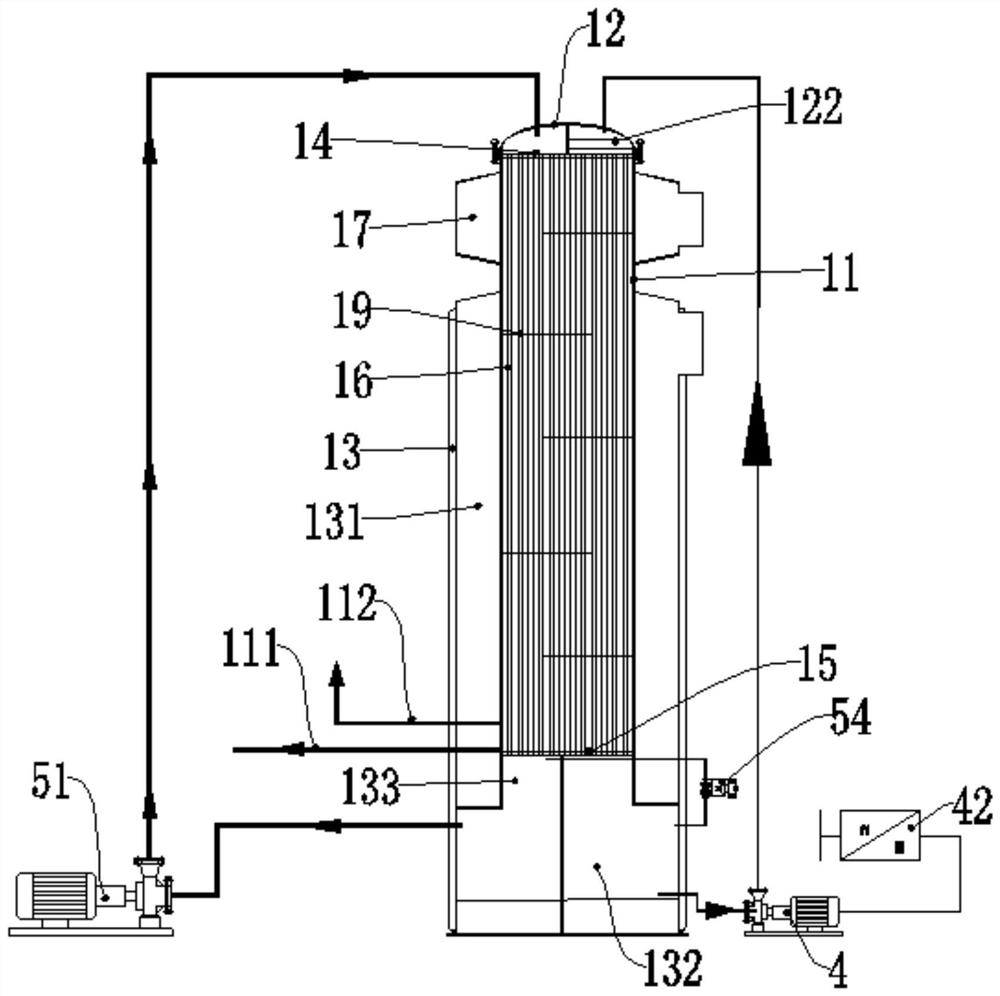

[0058] like image 3 As shown, the isothermal concentration tower body 13 is sleeved on the outside of the same-body double-effect heater 1, and a secondary steam collecting cavity 131 is formed between the isothermal concentration tower body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com