Metal pattern plate manipulator pre-aligning mechanism and metal pattern plate feeding method and application

A mask and pre-alignment technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of damaged mask, clamping and positioning speed and force can not be flexibly controlled, etc., to achieve high speed , precise positioning and clamping, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

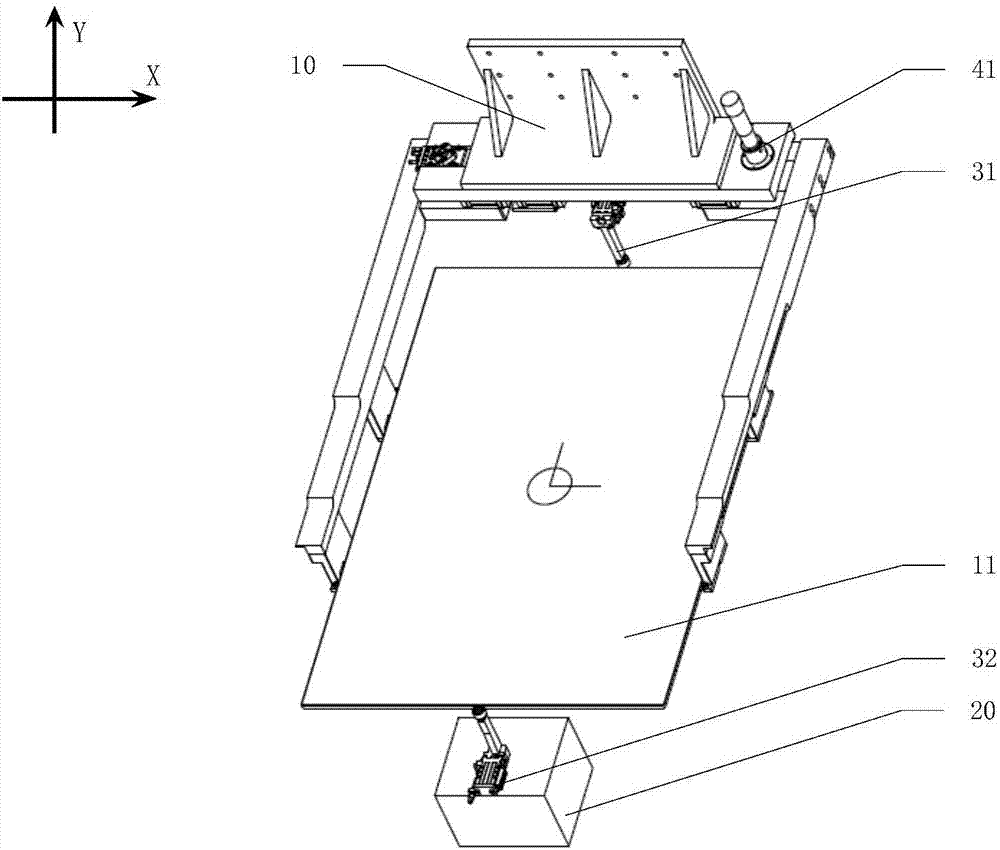

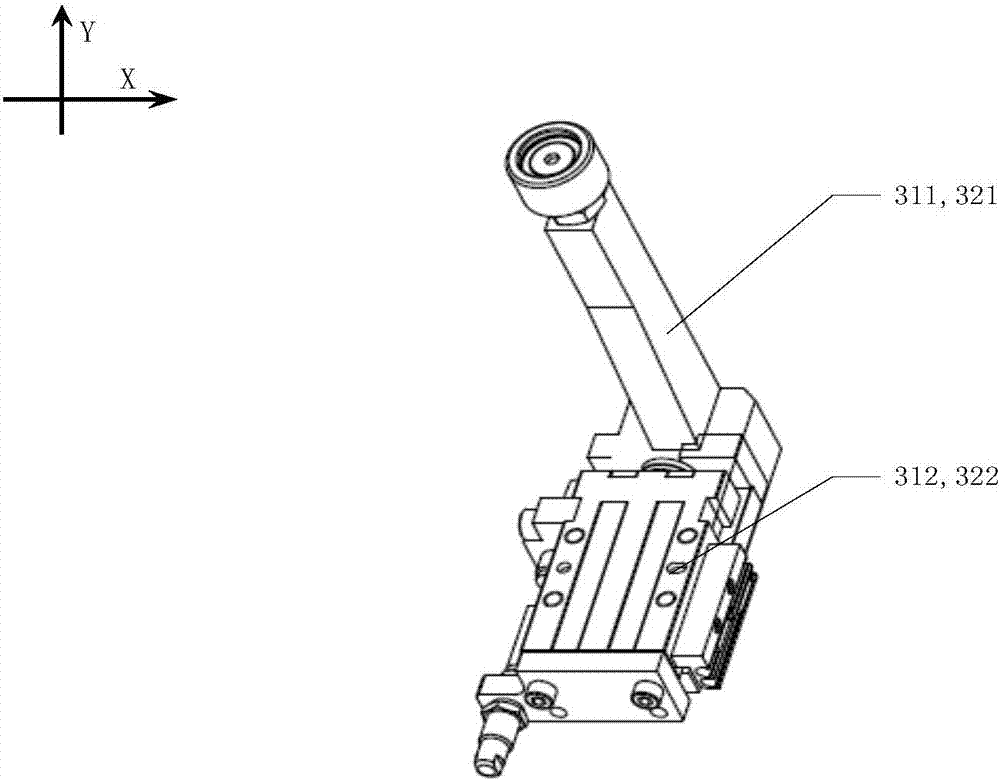

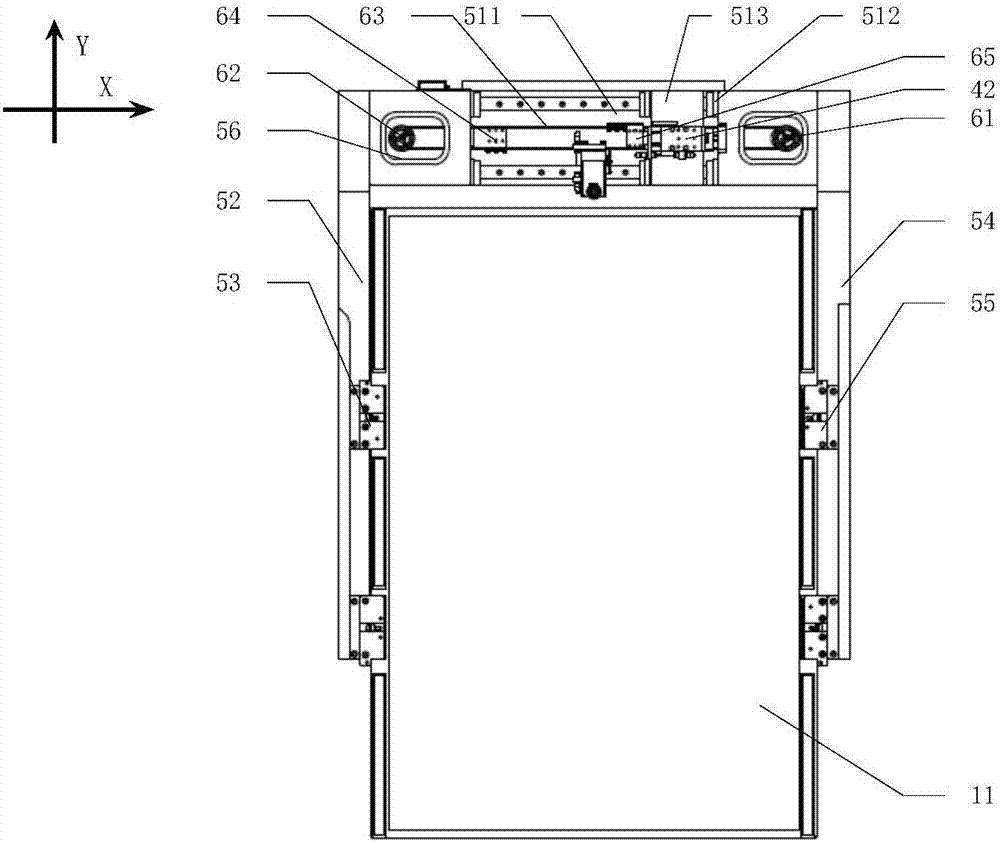

[0062] Please refer to figure 1 and image 3 , the X-direction drive mechanism includes an X-direction motor driver 41 and an X-direction cylinder driver 42, the X-direction cylinder driver 42 is arranged on the second slider 513, and the X-direction cylinder driver 42 is arranged through the guide rail on the base 10.

[0063] Please refer to image 3 , the X-direction transmission mechanism can be a belt transmission mechanism or a chain transmission mechanism, and the belt transmission mechanism is taken as an example below, and the belt transmission mechanism includes a driving wheel 61, a driven wheel 62, an intermediate winding member 63, and a first connecting member 64 and the second connecting piece 65, the driving wheel 61 and the driven wheel 62 are connected and interlocked through the intermediate winding member 63, the X-direction motor driver 41 drives the driving wheel 61, and one end of the first connecting piece 64 is connected to The other end of the left...

Embodiment 2

[0073] Please refer to Figure 7 and Figure 8 , the X-direction drive mechanism includes a left motor driver 43, a right motor driver 44, a left cylinder driver 45 and a right cylinder driver 46, and the left cylinder driver 45 and the right cylinder driver 46 are respectively arranged on two of the second slide blocks 513 , the left cylinder driver 45 and the right cylinder driver 46 are arranged on the base 10 through the guide rail.

[0074] The X-direction transmission mechanism includes a left rack and pinion transmission mechanism and a right rack and pinion transmission mechanism symmetrically arranged on the base 10, and the left and right rack and pinion transmission mechanisms are all along the X direction. Set on the base 10, the left rack and pinion transmission mechanism includes a meshing left gear 71 and a left rack 72, and the right rack and pinion transmission mechanism includes a meshing right gear 73 and a right rack 74. The left motor driver 43 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com