Stainless steel service plate recycling device based on vibration screen

A recovery device and vibrating screen technology, which is applied in the direction of filtering, solid waste removal, solid separation, etc., can solve the problems of time delay, waste of labor, slowing down of speed, etc., and achieve the reduction of labor use, efficient and perfect recycling, and device structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

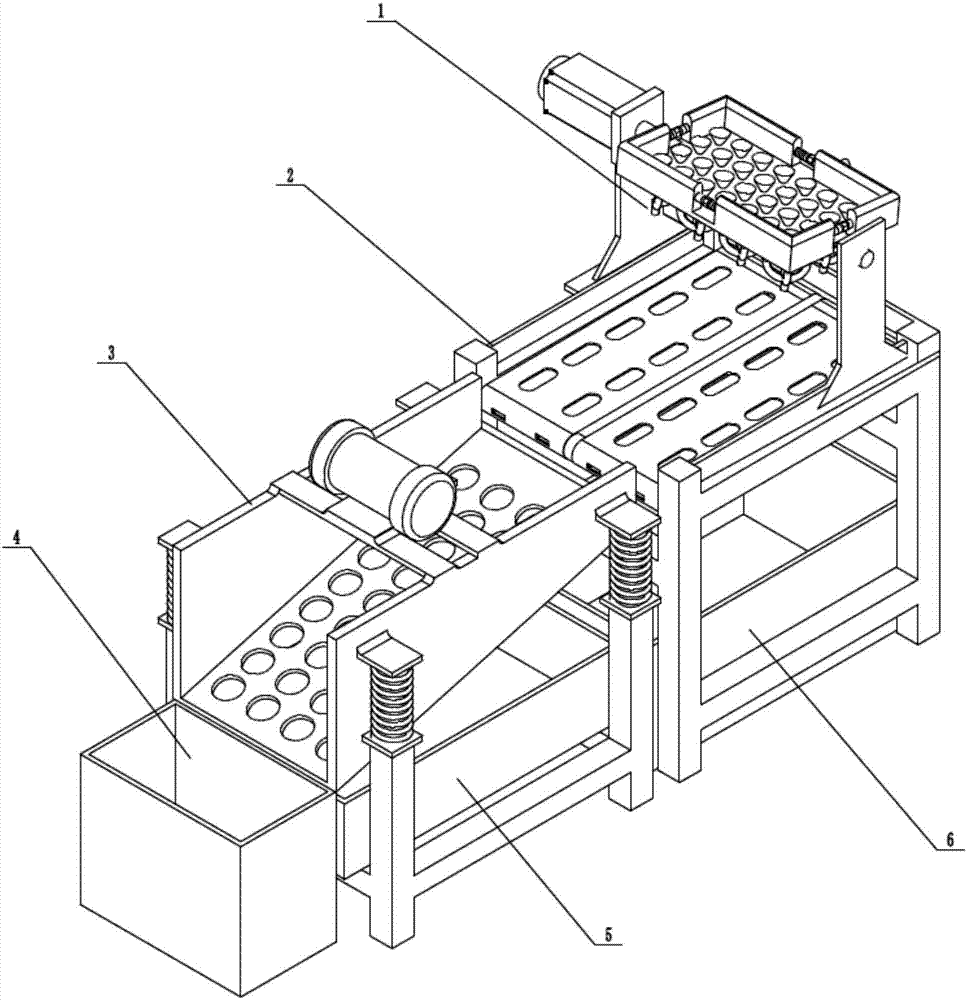

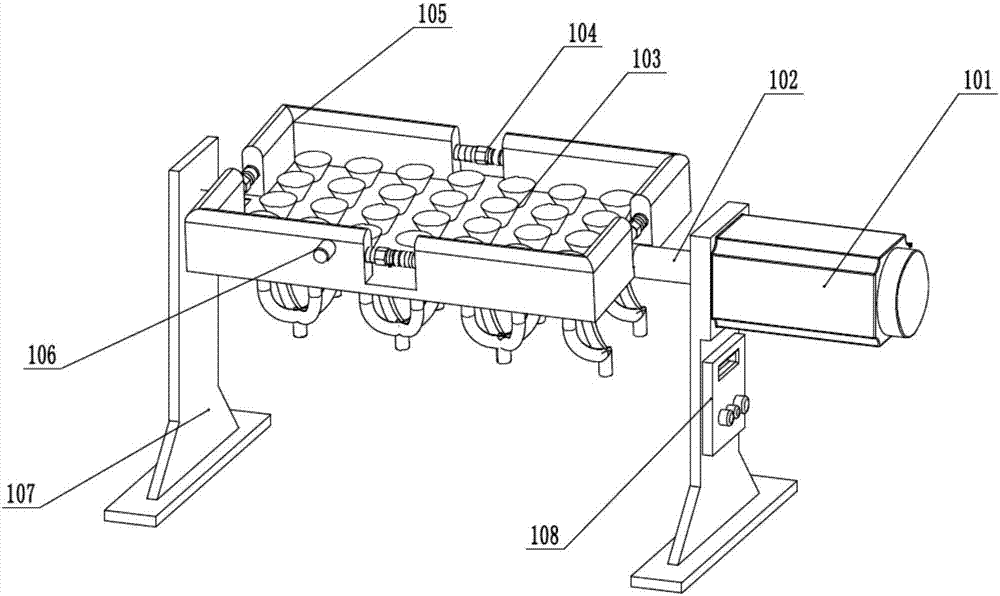

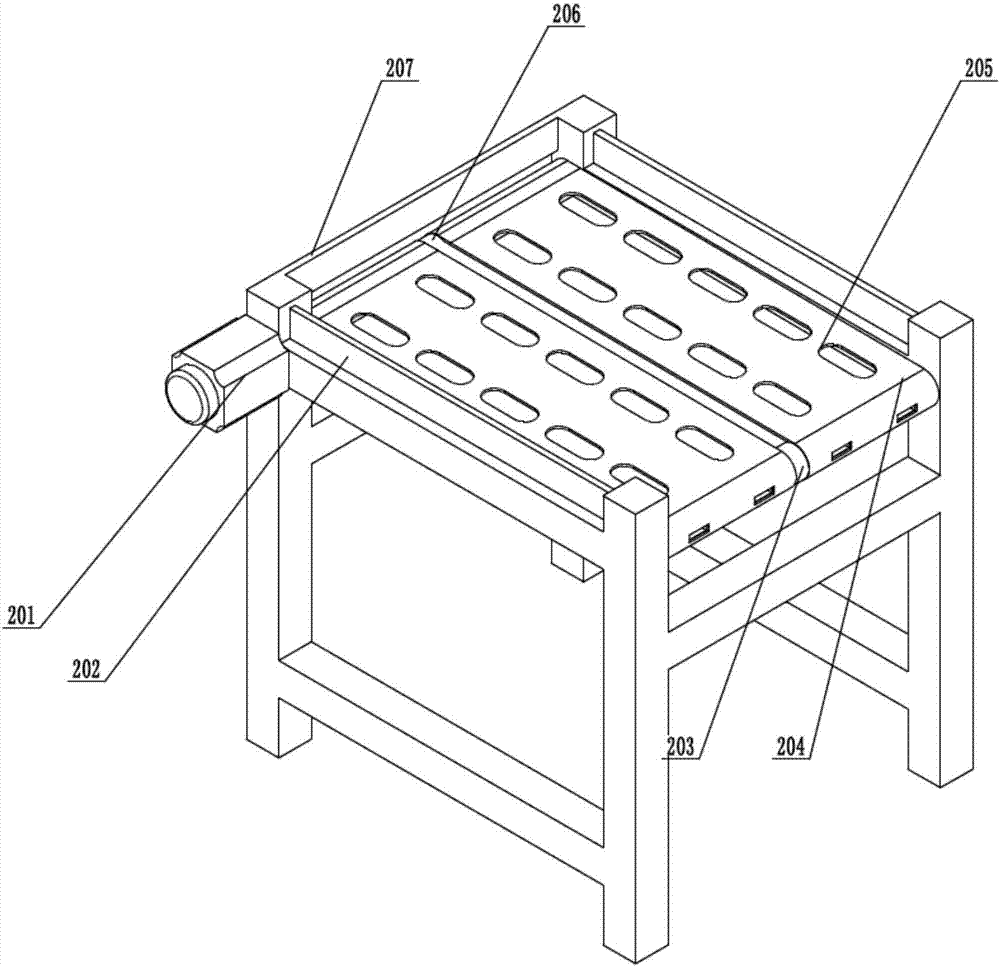

[0016] A stainless steel plate recovery device based on a vibrating screen is composed of a plate turning mechanism 1, a vibrating screen 3, a conveying mechanism 2, a plate recovery box 4, a front meal recovery box 6, and a rear meal recovery box 5. The turning mechanism 1 is composed of turning motor 101, turning shaft 102, turning plate 105, vacuum generator 103, bracket adjusting screw 104, distance sensor 106, bracket 107, controller 108, turning motor 101 is connected to turning shaft 102 , Mounted on the bracket 107, the turnover plate 105 is fixed on the turnover shaft 102 and the turnover shaft 102 penetrates the turnover plate 105, the vacuum generator 103 is installed in the turnover plate 105, and the distance sensor 106 is installed on the side plate of the turnover plate 105. The conveying mechanism 2 is composed of a conveying motor 201, a driving shaft 206, a driven shaft 203, a conveying belt 204, a separation hole 205, a splash-proof side baffle 202, and a spla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com