Optical microstructure and manufacturing method of optical microstructure layer, light guide component and display device

A technology of optical microstructure and light guide components, which is applied in optical elements, light guides, optics, etc., can solve the problems of holographic lens phase distribution changes, limited mass production feasibility, product reliability, and defects, so as to avoid phase distribution changes , the effect of good mass production feasibility and product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

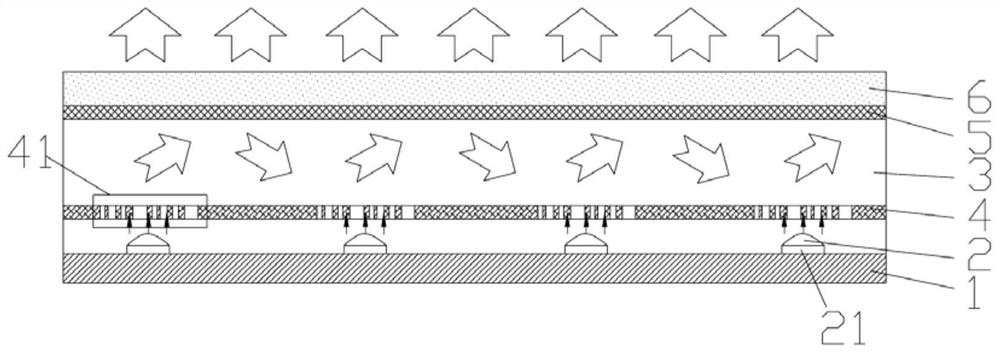

[0055] In order to enable those skilled in the art to better understand the technical solution of the present invention, the method for fabricating the optical microstructure, the light guide assembly and the display device provided by the present invention will be described in detail below with reference to the accompanying drawings.

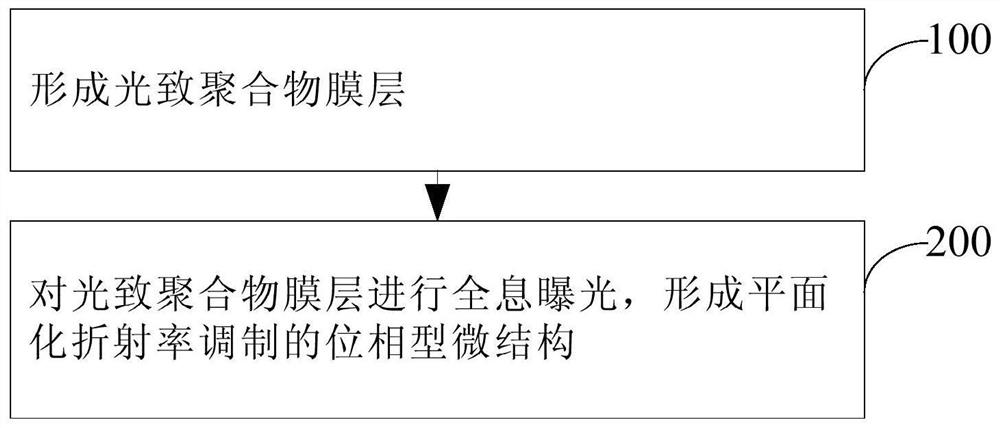

[0056] see figure 1 , the preparation method of the optical microstructure provided by the invention, it comprises:

[0057] 100, forming a photopolymer film layer;

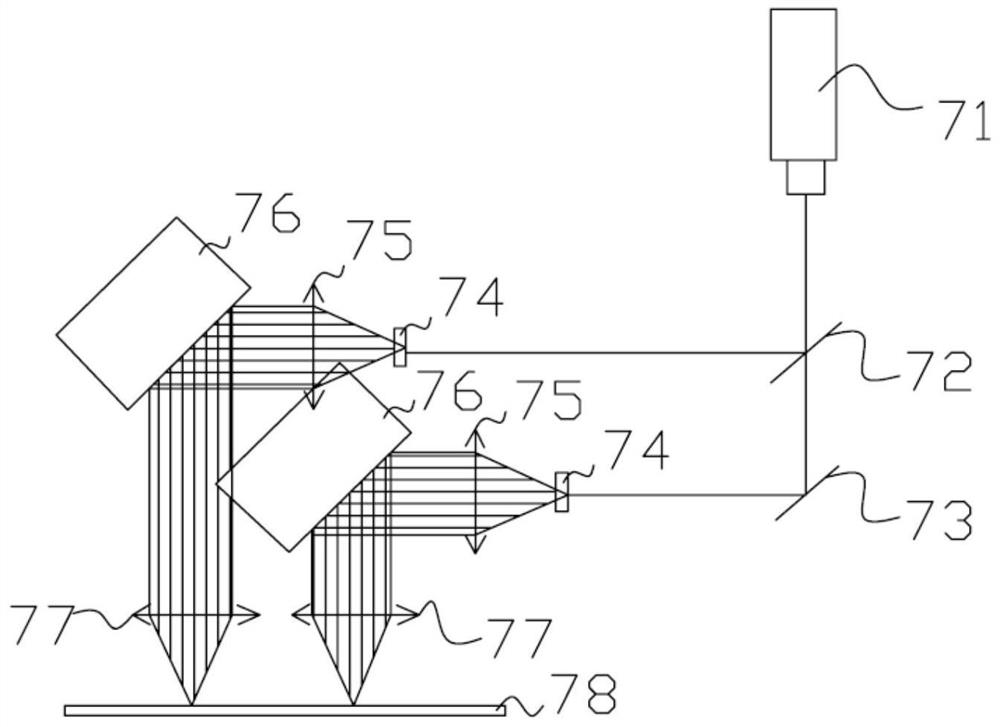

[0058] 200. Perform holographic exposure on the photopolymer film layer to form a phase-type microstructure with planarized refractive index modulation.

[0059] The above-mentioned photopolymer film layer is a kind of transparent resin, which has the advantages of high photosensitivity, high resolution, high diffraction efficiency and high signal-to-noise ratio. The photopolymer film layer can change its internal refractive index after being exposed to form a refractive index m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com