A kind of air grid and the low-pressure quenching process when adopting the air grid tempered glass

An air grille and quenching technology, which is applied in the tempering of glass, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of restricting ultra-thin glass tempering, high wind pressure of fans, and easy bending of glass, so as to reduce energy consumption, fan The effect of improving efficiency and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings.

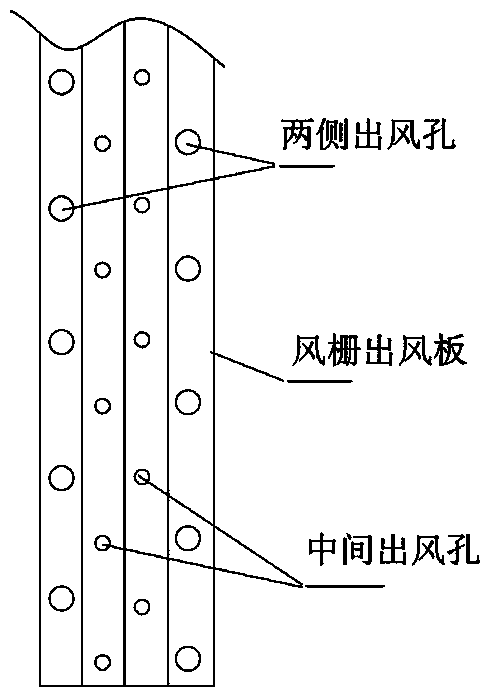

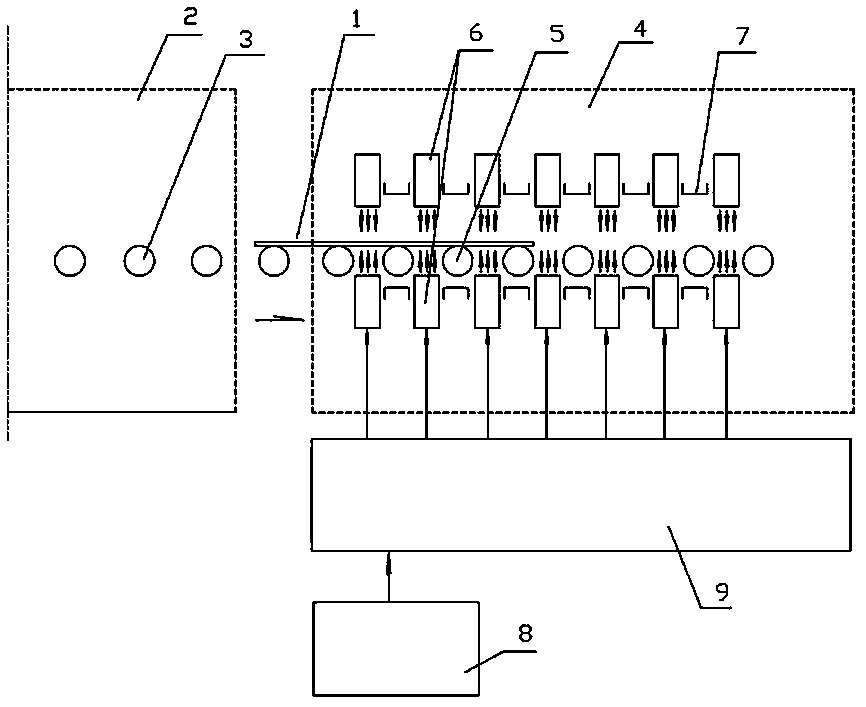

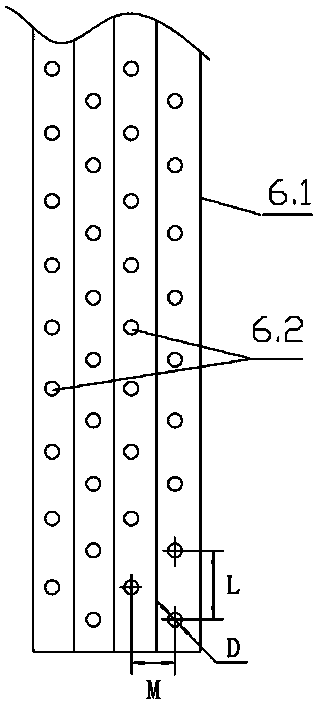

[0018] Such as figure 2 As shown, the processing of tempered glass is mainly divided into two steps: the glass 1 enters the heating chamber 2 from the loading table, and is heated on the reciprocating ceramic roller table 3 until it reaches a temperature suitable for tempering (due to the original glass plate used by each manufacturer) Different, the softening point is different, the color is different, the thickness error is different, and the heating time is different. If the glass is broken in the quenching section, it means that the heating time is not enough. If there are ribs and pits on the glass surface, it means that the heating time is too long, so The heating time in actual production should be adjusted accordingly according to specific conditions); the heated glass 1 enters the cooling chamber 4 for quenching (the glass 1 is blown on the reciprocati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com