Device for preparing benzaldehyde through toluene oxidation

A technology of benzaldehyde and toluene, which is applied in the field of devices for preparing benzaldehyde by oxidation of toluene, can solve the problems of complicated operation and high cost, and achieve the effect of simple device principle, simple sampling, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

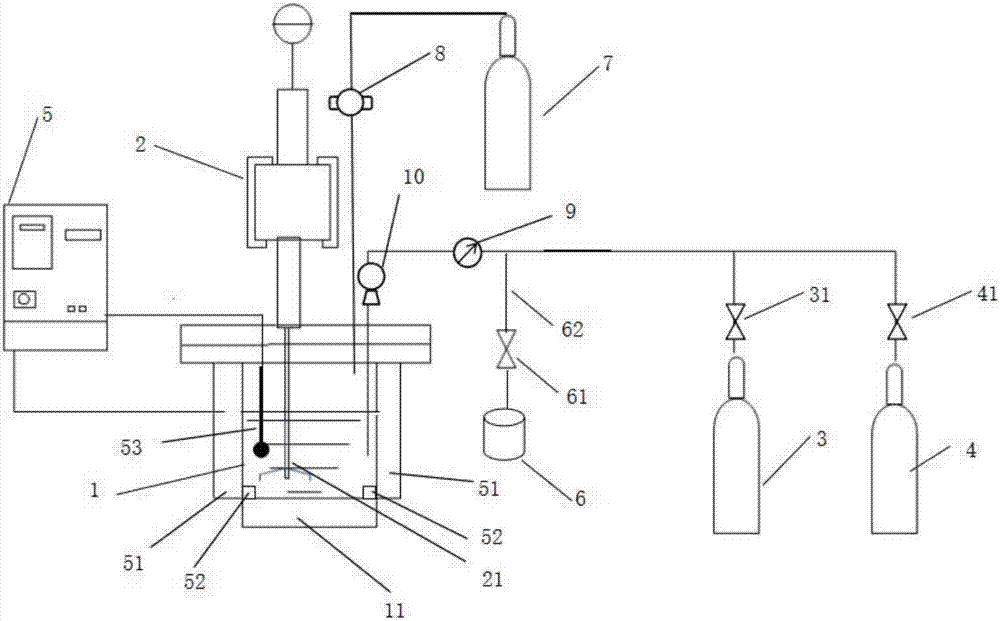

[0017] Such as figure 1 As shown, a device for preparing benzaldehyde by oxidation of toluene includes: autoclave 1, stirrer 2, oxygen bottle 3, air bottle 4, sampler 6, temperature control device 5;

[0018] Wherein one end of the agitator 2 is arranged in the autoclave 1 for stirring the reactants, the autoclave 1 is connected with the oxygen bottle 3 and the air bottle 4 successively through pipelines, and is provided with a first valve 31, a second Two valves 41, the first valve 31 is connected in parallel with the second valve 41, the first valve 31 controls the oxygen cylinder 3, the second valve 41 controls the air cylinder 4, and the oxygen in the oxygen cylinder 3 is opened to open the first valve 31. Into the autoclave 1, wherein one end of the pipeline goes deep i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com