Oil primer collector for lithium-ion battery and preparation method and application of oil primer collector

A technology for lithium-ion batteries and current collectors, which is applied to battery electrodes, secondary batteries, electrode carriers/collectors, etc., to achieve the effect of short preparation time and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

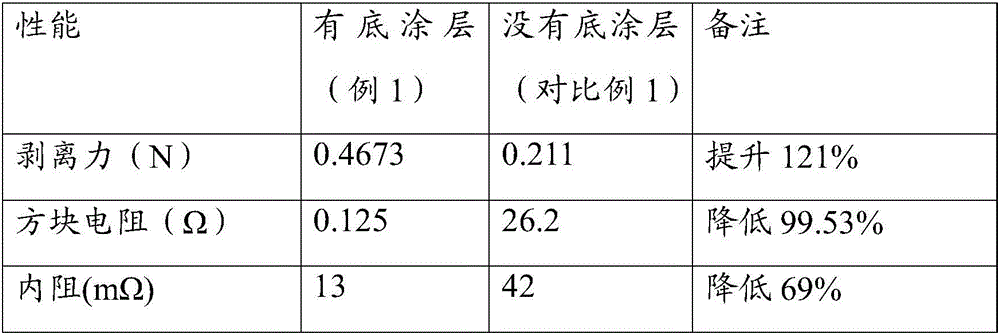

Embodiment 1

[0067] A preparation method of an oily primer coating current collector, comprising the following steps:

[0068] 1. Add 60g of PEG to 1380g of NMP, stir in the dispersion tank for 30min to dissolve completely;

[0069] 2. Add 200g of graphene (flaky) and 400g of 350G (spherical) to the above dispersion tank and stir for 30min. After the dispersion is uniform, use a sand mill to sand 4-5 times until the particle size D50 of the mixture is 20μm That's it, stop sanding;

[0070] 3. Add 15g of PVA (molecular weight is 5-300,000) in the dispersing tank of step 2, stir, obtain the oily primer slurry that viscosity is about 4Pa·s;

[0071] 4. The obtained oily primer slurry is coated on the surface of the aluminum foil current collector base material by scraper technology, and after drying, a primer layer with a thickness of 0.1 micron is formed to obtain an oily primer collector.

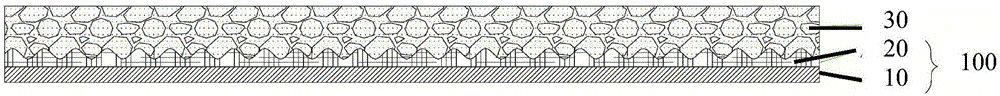

[0072] figure 1 It is a schematic structural view of the oil-based primer-coated current collector...

Embodiment 2

[0103] A preparation method of an oily primer coating current collector, comprising the following steps:

[0104] 1. Add 72g of Triton X-100 into 1560g of NMP, and stir in the dispersion tank for 60min to dissolve completely;

[0105] 2. Add 100g of KS-6 (flaky) and 500g of Ketjen Black (spherical) to the above dispersion tank and stir for 2 hours. After the dispersion is uniform, use a sand mill to sand 4-5 times until the particle size of the mixture is D50 is 20-90μm, stop sanding;

[0106] 3. Add 18g of PVDF (molecular weight is 400,000) to the dispersing tank of step 2, stir to obtain an oily primer slurry with a viscosity of about 3Pa·s;

[0107] 4. Apply the obtained oily primer slurry on the surface of the copper foil current collector base material by scraper technology, and form a primer layer after drying to obtain an oily primer collector.

[0108] The undercoat layer of the oily undercoated current collector obtained in Example 2 is coated with a positive electr...

Embodiment 3

[0110] A preparation method of an oily primer coating current collector, comprising the following steps:

[0111] 1. Add 63g of polyvinylpyrrolidone PVP into 1400g of NMP, and stir in the dispersion tank for 45min to dissolve completely;

[0112] 2. Add 250g of flake graphite (flaky) and 300g of acetylene black (spherical) to the above dispersion tank and stir for 2 hours. After the dispersion is uniform, use a sand mill to perform sand grinding for 4-5 times until the particle size D50 of the mixture is 20-90μm is enough, stop sanding;

[0113] 3. Add 15g of vinylidene fluoride-hexafluoropropylene copolymer P(VDF-HFP) (molecular weight: 1,000,000) to the dispersion tank in step 2, and stir to obtain an oily primer slurry with a viscosity of about 8Pa·s material;

[0114] 4. Apply the obtained oily primer slurry on the surface of the copper foil current collector base material by scraper technology, and form a primer layer after drying to obtain an oily primer collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com