Efficient and low-toxicity oil dispersant for spilled oil and synthesizing method of efficient and low-toxicity oil dispersant

A high-efficiency, low-toxicity, synthesis method technology, applied in separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc., can solve problems such as death, irreparable, and safety damage to the marine ecological environment, and achieve good results Compatibility and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

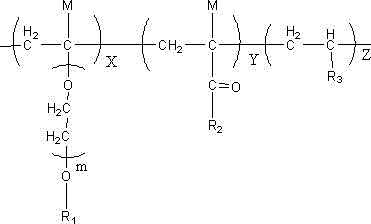

Image

Examples

Embodiment 1

[0035] A method for synthesizing a high-molecular degreasing agent for oil spills is prepared by stirring each comonomer in a solvent under the condition of the presence of an initiator, carrying out a copolymerization reaction and corresponding post-treatment.

[0036] 1. Raw materials

[0037] Monomer: Isooctyl Acrylate (2EHA)

[0038] Styrene (St)

[0039] Lauric acid (DA)

[0040] Butylamine (BA)

[0041] Molar ratio 2EHA:St:LA:BA=1:1:1.5:1

[0042] Initiator: benzoyl peroxide (BPO), the amount used in the reaction system is 0.5% of the monomer mass

[0043] Solvent: Methyl Oleate (3:1 solvent to all other ingredients by weight)

[0044] 2. Process

[0045] In a stainless steel reaction kettle equipped with a stirrer, a constant pressure drop tank, a thermometer and a condenser, first put DA and 70% solvent methyl oleate into the reaction kettle, stir and heat to melt the lauric acid, and continue heating When the temperature reaches 60°C, add dropwise the methyl olea...

Embodiment 1

[0047] In Example 1, 20% of the initiator solid is first thrown into the reactor, heated together with DA and 70% of the solvent, and the remaining initiator is added dropwise to the solution of the monomer into methyl oleate in the reactor, and other Constantly, obtain the polymer oil dispersant product XYJ-2 for oil spill of the present invention

Embodiment 3

[0049] 1. Raw materials:

[0050] Monomer: lauryl acrylate (LA)

[0051] N-vinylpyrrolidone (NVP)

[0052] Lauric acid (DA)

[0053] Styrene (St)

[0054] Butylamine (BA)

[0055] Molar ratio 1:1.5:2:1:1

[0056] Initiator: Azobisisobutyronitrile (AIBN), the amount used in the reaction system is 0.5% of the monomer mass

[0057] Solvent: butanone (3:1 weight ratio of solvent to all other raw materials).

[0058] 2. Process

[0059] In a stainless steel reaction kettle equipped with a stirrer, a constant pressure drop tank, a thermometer and a condenser, put LA and 70% butanone into the reaction kettle first, stir and heat the solid to melt, and continue heating to a temperature of 60°C. At the same time, dropwise add the methyl ethyl ketone solution mixed with LA, NVP, St and AIBN, and control the dropwise addition time at 1~1.5h. After the dropwise addition, raise the temperature to 70°C and keep it warm for 2h to make the reaction complete. After the reaction, use tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com