A kind of nano silicon dioxide-acrylic acid composite fluorescent resin and its preparation method

A technology of nano-silica and composite fluorescence, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of limited fluorescent paint preparation and application, aggregation-induced quenching, fluorescent powder easy to fall off, etc., to achieve uniform mechanics and Fluorescence performance, overcoming aggregation-induced quenching effect, expanding types and application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A nanometer silicon dioxide-acrylic acid composite fluorescent resin, comprising:

[0042] Fluorescent nano silica, 3wt%;

[0043] Acrylate monomer mixture, 35wt%;

[0044] Mixed organic solvent, 60wt%;

[0045] Initiator azobisisobutyronitrile, 1wt%;

[0046] Chain transfer agent dodecyl mercaptan, 1wt%,

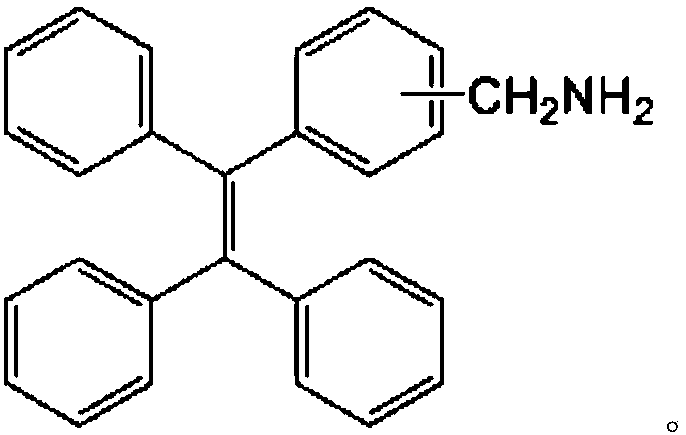

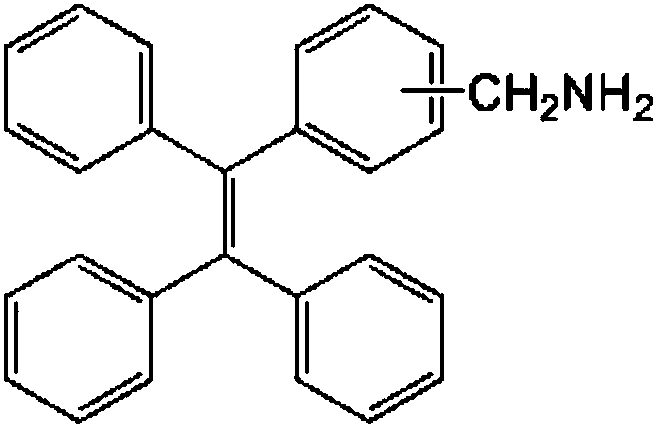

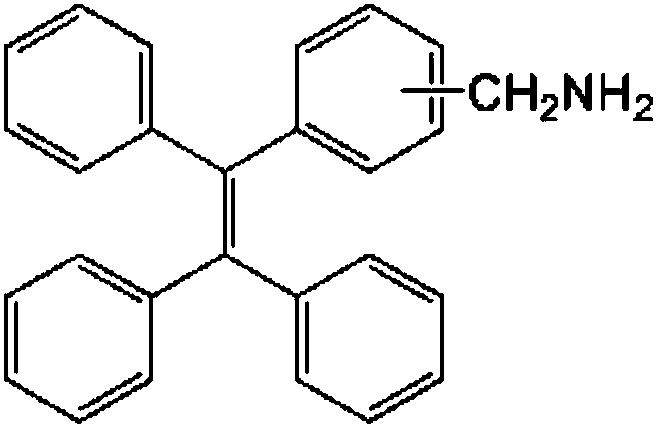

[0047] Wherein, the fluorescent nano-silica is chemically modified and modified by tetraphenylethylene derivatives.

[0048] The acrylate monomer mixture includes:

[0049] Methyl methacrylate, 55% by weight;

[0050] Styrene, 5wt%;

[0051] Isooctyl acrylate, 10wt%;

[0052] Butyl acrylate, 20wt%;

[0053] Hydroxyethyl acrylate, 8wt%;

[0054] Methacrylic acid, 2 wt%.

[0055] Described mixed organic solvent comprises:

[0056] Xylene, 35vol%;

[0057] Butyl acetate, 50vol%;

[0058] Solvent oil S100#, 15vol%.

[0059] Nano silica-acrylic acid composite fluorescent resin is prepared through the following steps:

[0060] The first step: according to th...

Embodiment 2

[0069] A nanometer silicon dioxide-acrylic acid composite fluorescent resin, comprising:

[0070] Fluorescent nano-silica, 1wt%;

[0071] Acrylate monomer mixture, 50wt%;

[0072] Mixed organic solvent, 47wt%;

[0073] Initiator azobisisobutyronitrile, 0.5wt%;

[0074] Chain transfer agent dodecyl mercaptan, 1.5 wt%,

[0075] Wherein, the fluorescent nano-silica is chemically modified and modified by tetraphenylethylene derivatives.

[0076] The acrylate monomer mixture includes:

[0077] Methyl methacrylate, 40wt%;

[0078] Styrene, 10wt%;

[0079] Isooctyl acrylate, 15wt%;

[0080] Butyl acrylate, 25wt%;

[0081] Hydroxyethyl acrylate, 5wt%;

[0082] Methacrylic acid, 5 wt%.

[0083] Described mixed organic solvent comprises:

[0084] Xylene, 55vol%;

[0085] Butyl acetate, 35vol%;

[0086] Solvent oil S100#, 10vol%.

[0087] Nano silica-acrylic acid composite fluorescent resin is prepared through the following steps:

[0088] The first step: according to the ...

Embodiment 3

[0097] A nanometer silicon dioxide-acrylic acid composite fluorescent resin, comprising:

[0098] Fluorescent nano silica, 2wt%;

[0099] Acrylate monomer mixture, 40wt%;

[0100] Mixed organic solvent, 51wt%;

[0101] Initiator azobisisobutyronitrile, 5wt%;

[0102] Chain transfer agent dodecyl mercaptan, 2wt%,

[0103] Wherein, the fluorescent nano-silica is chemically modified and modified by tetraphenylethylene derivatives.

[0104] The acrylate monomer mixture includes:

[0105] Methyl methacrylate, 30wt%;

[0106] Styrene, 7wt%;

[0107] Isooctyl acrylate, 30wt%;

[0108] Butyl acrylate, 22wt%;

[0109] Hydroxyethyl acrylate, 10wt%;

[0110] Methacrylic acid, 1 wt%.

[0111] Described mixed organic solvent comprises:

[0112] Xylene, 50vol%;

[0113] Butyl acetate, 30vol%;

[0114] Solvent oil S100#, 20vol%.

[0115] Nano silica-acrylic acid composite fluorescent resin is prepared through the following steps:

[0116] The first step: according to the desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com