An on-orbit maintenance circuit for lithium-ion batteries

A lithium-ion and battery technology, which is applied in battery circuit devices, charging and maintenance charging/discharging, circuit devices, etc., can solve the problems of proportional increase in working heat consumption, waste of satellite resources, and increase in research and development costs. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

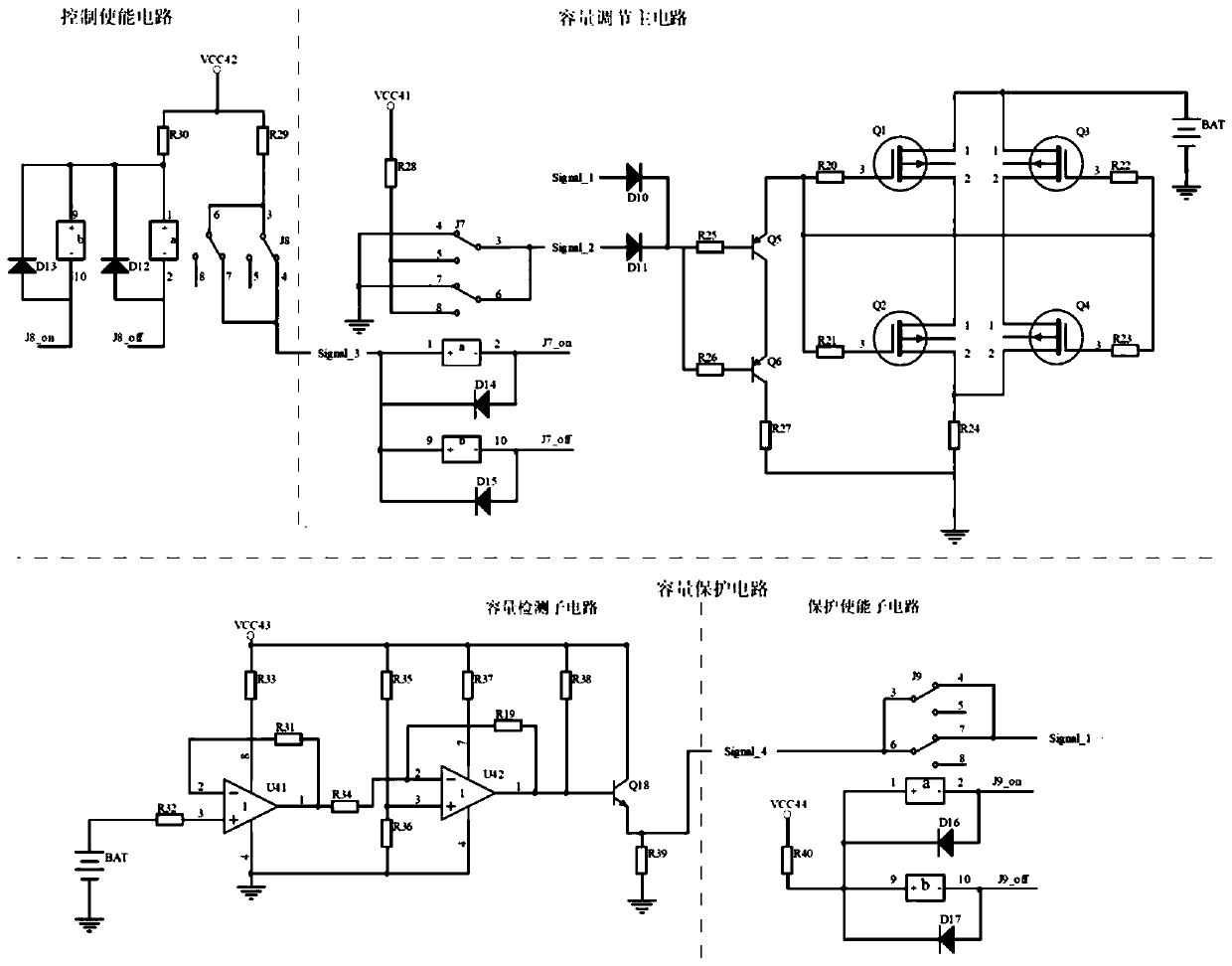

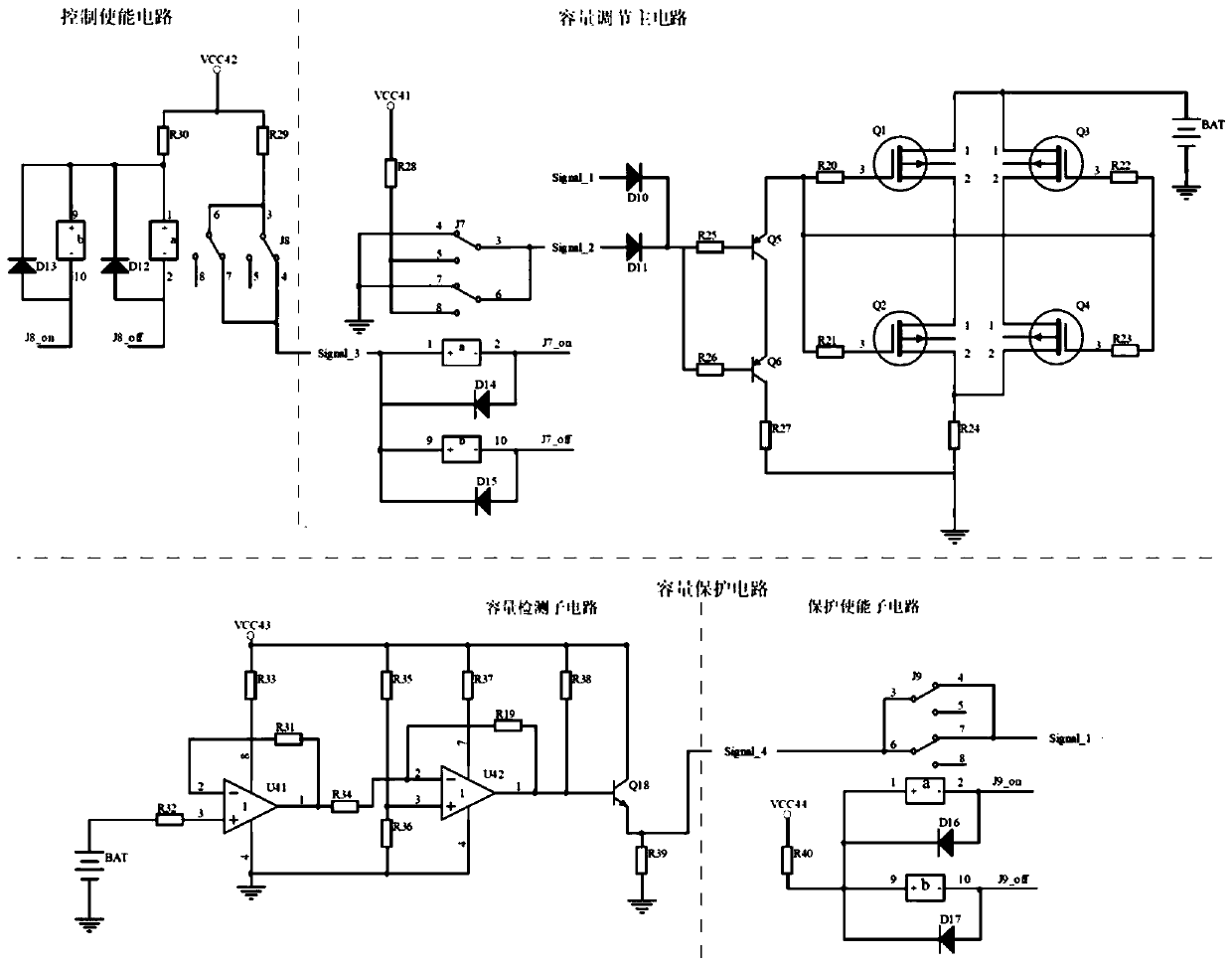

[0035] like figure 1 As shown, in the capacity adjustment main circuit, the J7 switch adopts a magnetic latching relay, the MOS transistors Q1~Q4 act as a shunt, the transistors Q5 and Q6 act as a driver, and BAT is a lithium-ion battery. The capacity adjustment main circuit consists of two parallel and two series shunt Composed of switch tube, triode, power resistor, relay and diode. In the initial state, the relay J7 is turned off, the driving transistors Q5 and Q6 are turned off, and the MOS transistors Q1-Q4 are turned off. Taking the magnetic latching relay shown in J7 as an example, pins 1 and 2 are a set of wire packages (wire package a), and pins 9 and 10 are another set of wire packages (wire package b). 3, 4, 5 pins and 6, 7, 8 pins respectively form two groups of contact switches, and the on and off actions of the contact switches are controlled by two groups of wire packs respectively. In order to prevent misoperation of contacts, two sets of contact switches are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com