Industrial organic solid waste and sludge high-temperature incineration harmless treatment method

A technology for organic solids and wastes, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as visual pollution, large stacking area, and air pollution, and achieve improved air permeability, increased processing capacity, and reliable temperature protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

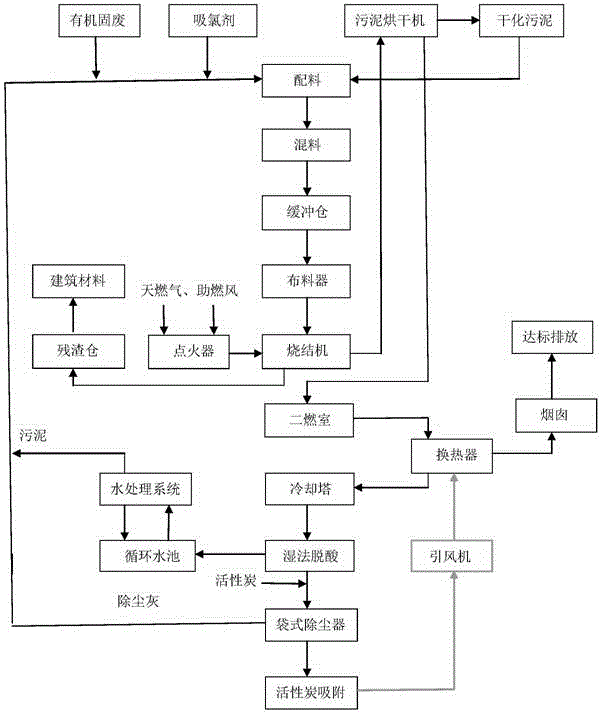

[0036] Such as figure 1 Shown: crush industrial organic solid waste to 0-15mm for later use;

[0037] Take 650kg of sludge (water content 90%), add 300kg of industrial organic solid waste, 50kg of chlorine absorbing agent, stir and mix with a double-shaft mixer, transport the mixed material to the buffer warehouse, and mix it with a screw conveyor. The material is sent to the incinerator, and is ignited and incinerated at the same time. The incineration temperature is controlled at 1000°C±50°C. The incineration process is completed under the action of the exhaust fan. The high-temperature flue gas generated during the incineration process enters the dryer for sludge drying. After being treated by the flue gas purification system, it is discharged up to the standard.

Embodiment 2

[0039] Such as figure 1 Shown: crush industrial organic solid waste to 0-15mm for later use;

[0040]Take 800kg of sludge (water content 90%), add 400kg of industrial organic solid waste, 60kg of chlorine absorbing agent, stir and mix with a double-shaft mixer, transport the mixed material to the buffer warehouse, and pass the material through the distribution roller. Put it into the box-type sintering machine, and ignite and incinerate at the same time. The incineration temperature is controlled at 1000°C±50°C. The incineration process is completed under the action of the exhaust fan. The high-temperature flue gas generated during the incineration process enters the dryer for sludge drying. After being treated by the flue gas purification system, it is discharged up to the standard.

Embodiment 3

[0042] Such as figure 1 Shown: crush industrial organic solid waste to 0-15mm for later use;

[0043] Take 700kg of sludge (water content 90%), add 350kg of industrial organic solid waste, 55kg of chlorine absorbing agent, stir and mix with a double-shaft mixer, transport the mixed material to the buffer warehouse, and pass the material through the distribution roller. Put it into the vertical walking sintering machine, and carry out ignition and incineration at the same time. The incineration temperature is controlled at 1000°C±50°C. The incineration process is completed under the action of the exhaust fan. The high-temperature flue gas generated during the incineration process enters the dryer for sewage After the mud is dried, it is treated by the flue gas purification system, and then discharged up to the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com