Ultrahigh-performance concrete well lid for municipal and electric power engineering and manufacturing technique of ultrahigh-performance concrete well lid

An ultra-high performance, power engineering technology, applied in water conservancy engineering, infrastructure engineering, artificial islands, etc., can solve the problems of poor impact resistance and fatigue performance, high manufacturing cost, short service life, etc., to achieve good anti-wear performance, Long service life and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

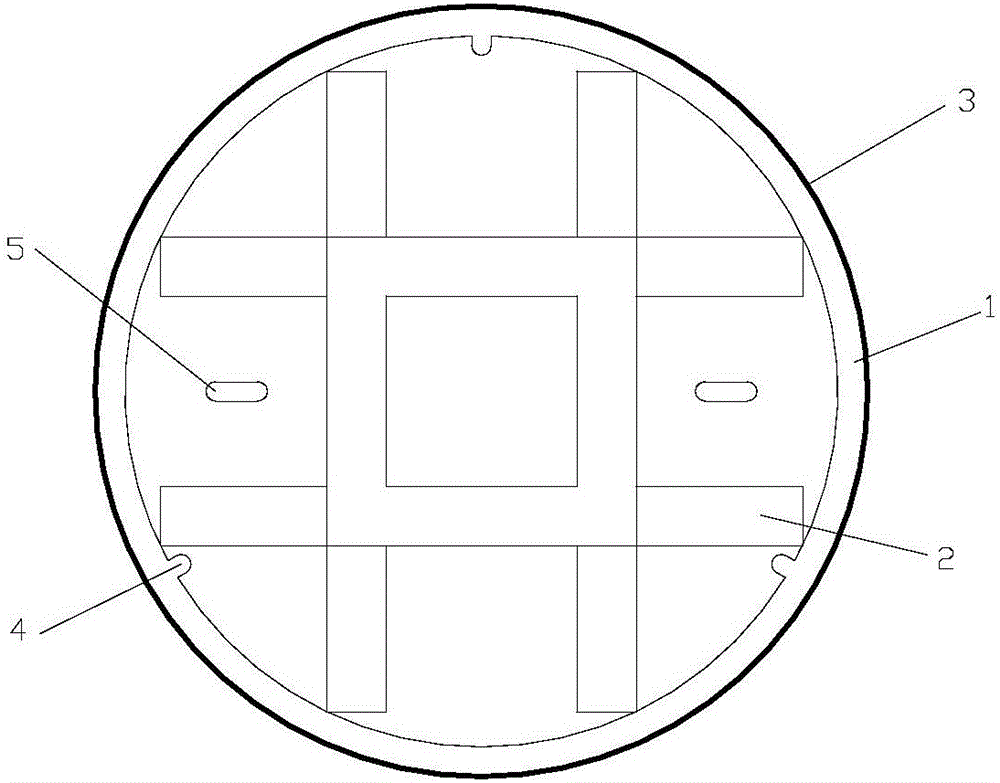

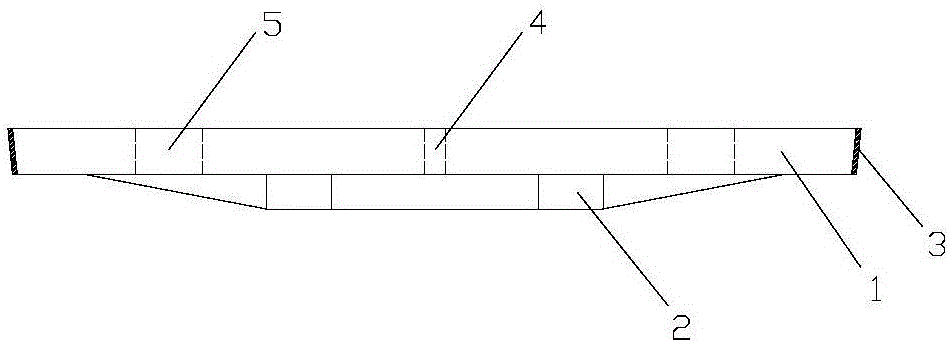

[0032] Embodiment one, see appendix figure 1 with 2 , an ultra-high-performance concrete manhole cover structure used in municipal and electric power engineering, including an ultra-high-performance concrete manhole cover 1 and manhole cover steel hoops 3 wrapped around the concrete manhole cover, in order to prevent the manhole cover from being partially damaged due to collision during transportation and installation Damaged, manhole cover steel hoop 2 is set. The concrete manhole cover is formed by one-time pouring of the upper conical manhole cover structure and the lower ribbed structure 2 using an integral mold and ultra-high-performance concrete; the conical manhole cover structure is a structure with a flat upper surface and a narrow top and bottom The well cover steel hoop is a circular structure with a wide top and a narrow bottom. The vertical height of the well cover steel hoop is the same as the height of the conical well cover structure. For the convenience of we...

Embodiment 2

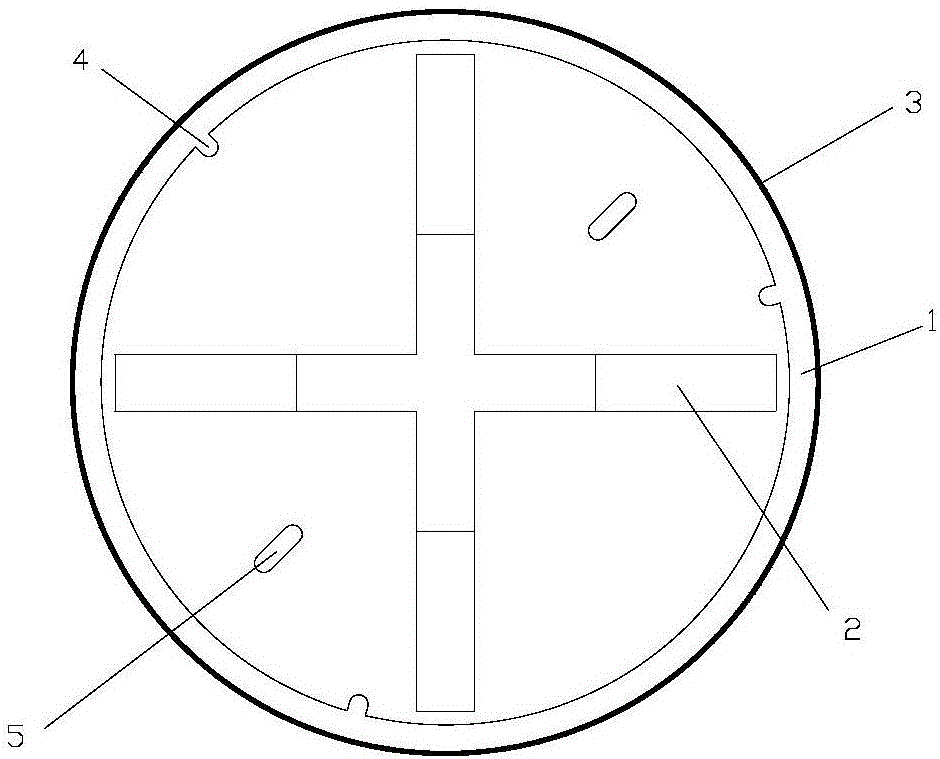

[0044] Embodiment two, see appendix image 3 with 4 , the overall structure of the second embodiment is the same as that of the first embodiment, except that the ribbed structure of the second embodiment is a cross-shaped rib structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com