Verticality Monitoring Device for Tool Holder Movement of Vertical Hobbing Machine

A technology of monitoring device and gear hobbing machine, which is applied to gear tooth manufacturing device, gear cutting machine, gear teeth, etc., can solve the problems of tool post deflection, trajectory correction without tool post movement, and hob scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

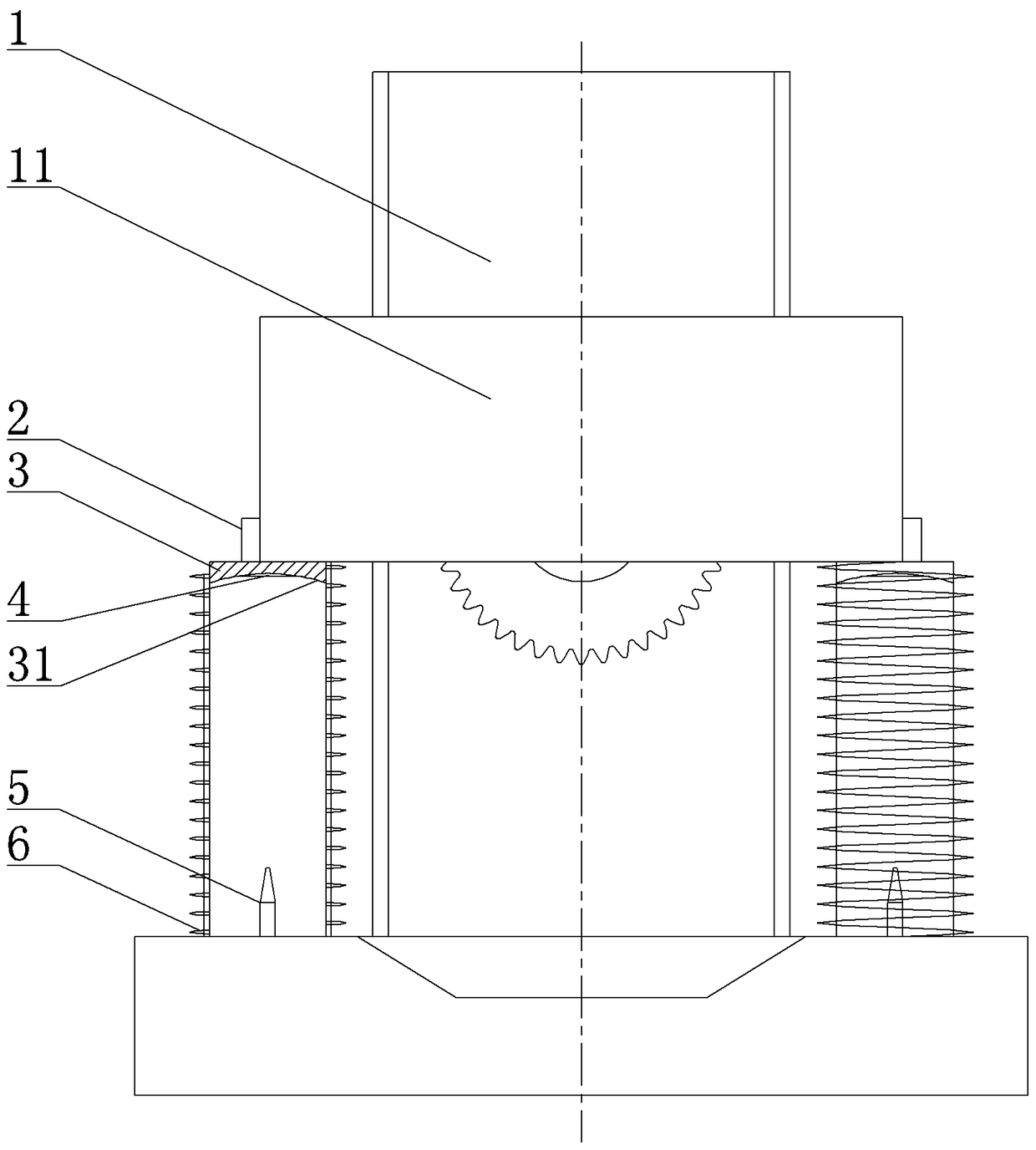

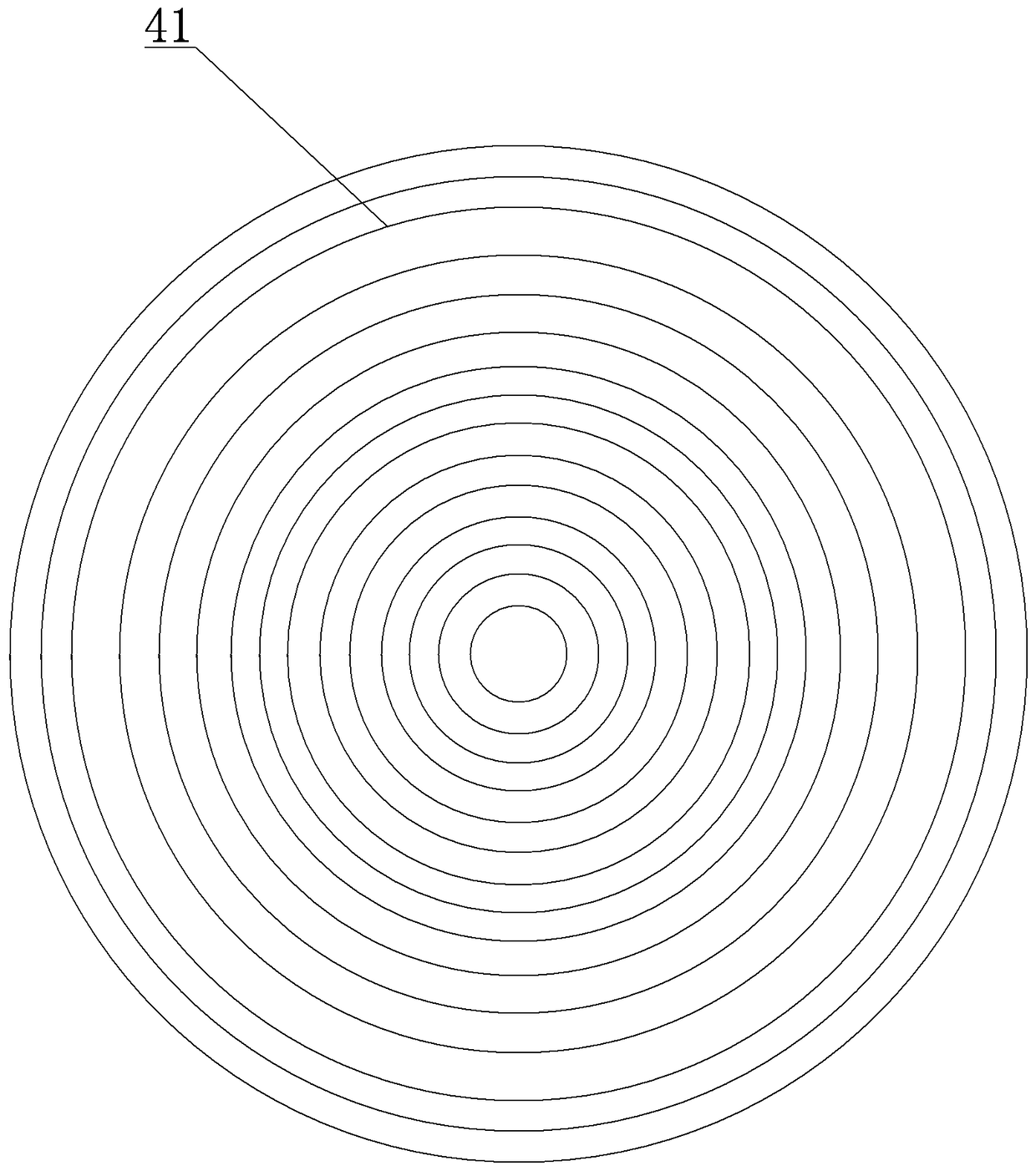

[0015] The reference signs in the accompanying drawings include: vertical hobbing machine body 1 , hob frame 11 , magnet 2 , balance plate 3 , scale grating 4 , reading head 5 , telescopic tube 6 , arc surface 31 , and grating stripes 41 .

[0016] The embodiment is basically as figure 1 and figure 2 Shown: vertical hobbing machine tool rest verticality monitoring device, including vertical hobbing machine body 1, vertical hobbing machine body 1 includes clamping seat and hob 11, also includes vertical monitoring system, vertical monitoring system includes grating displacement sensor and control Module, the grating displacement sensor comprises a scale grating 4 and a reading head 5. In this embodiment, the scale grating 4 is disc-shaped, and the disc-shaped scale grating 4 is provided with a circular ring, and the radius is along the center of the scale grating 4. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com