Mineral feed mould inhibitor and preparation method thereof

A mildew inhibitor and feed technology, applied in the field of aquaculture, can solve the problem that the anti-mildew material cannot meet the multi-functional requirements of the feed, etc., and achieve the effects of excellent biological health care function, increasing flavor and improving palatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

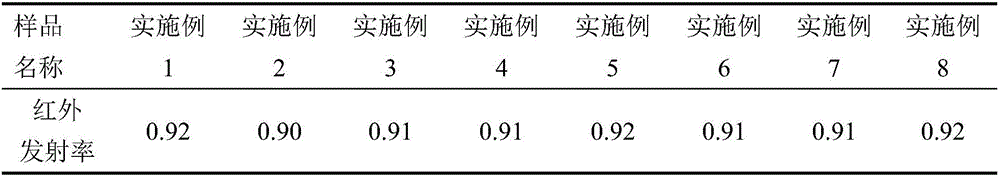

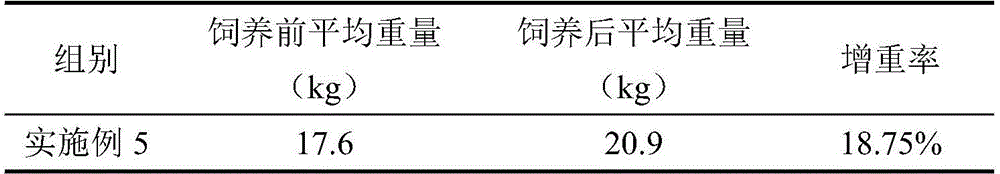

Examples

preparation example Construction

[0034] The preparation method of above-mentioned mineral type feed antifungal agent, the steps of this method are:

[0035] 1) Weigh each raw material by weight percentage;

[0036] 2) respectively pulverizing bentonite, tourmaline, limestone and diatomite by secondary wet ball milling process, the pulverized particle size is 0.05-0.5 mm, to obtain refined mineral powder;

[0037] 3) Fully mix the refined mineral powder in a mixer, put it into a high-temperature furnace for heat treatment, the heat treatment temperature is 400-450 ° C, and the heat treatment time is 2 hours to remove unstable impurities in the mineral powder and increase Mineral activity, and guarantee that tourmaline has not undergone biophase transformation;

[0038] 4) The mineral powder after the heat treatment in step 3) is fully mixed with the organic acid and cinnamon oil to obtain the mineral feed antifungal agent.

[0039] The invention also protects a feed added with the mineral feed antifungal age...

Embodiment 1

[0042] Present embodiment mineral type feed antifungal agent, the weight percent of the raw material of this antifungal agent forms: bentonite 20%; Tourmaline 30%; Limestone 10%; Diatomite 20%; Organic acid 15%; Cinnamon oil 5% . The organic acid in this embodiment is propionic acid.

[0043] The preparation method is:

[0044] 1) Weigh each raw material by the above weight percentage;

[0045] 2) Bentonite, tourmaline, limestone and diatomaceous earth are respectively pulverized by a secondary wet ball milling process, wherein the pulverized particle size of limestone is 0.5 mm, and the pulverized particle size of other minerals is 0.1 mm to obtain refined minerals Powder;

[0046] 3) Fully mix the refined mineral powder in a mixer, put it into a high-temperature furnace for heat treatment, the heat treatment temperature is 450°C, and the heat treatment time is 2h;

[0047] 4) The mineral powder after the heat treatment in step 3) is fully mixed with the organic acid and ...

Embodiment 2

[0049] The raw material type and weight percentage composition and preparation method of the mineral type feed antifungal agent of this embodiment are the same as in Embodiment 1. The difference is that during the preparation process, the heat treatment temperature is 400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com