A design method of airfoil allowance for curved blade forgings

A design method and bending technology, applied in the direction of calculation, instrument, geometric CAD, etc., can solve the problems of reducing the qualified rate of bending blade parts, uneven distribution of machining allowance, stress and deformation of bending blade parts, etc. The effect of uniform distribution of machining allowance, reasonable stress distribution and reduction of throwing repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] A method for designing an airfoil margin of a curved blade forging, comprising the following steps:

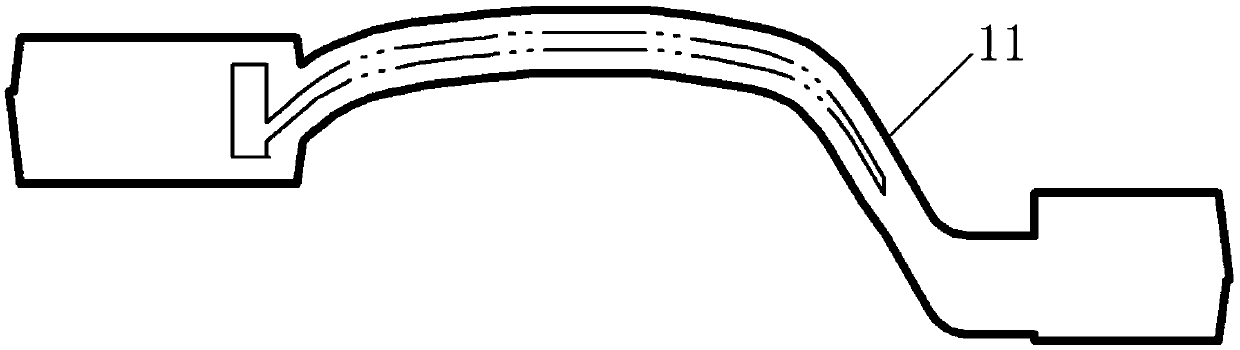

[0029] Step 1: Use 3D drawing software (UG software) to draw the 3D model of the blade body of the curved blade parts, such as image 3 shown;

[0030] Step 2: Execute the offset command in the 3D drawing software (UG software), set the offset amount according to the actual required machining allowance, and obtain the 3D model of the curved blade body after the allowance is increased, as shown in Figure 4 shown;

[0031] Step 3: According to the section distance of the drawing of the curved blade part, extract the part section line 1 and the forging section line 2 on the three-dimensional model of the curved blade part body after the margin is increased;

[0032] Step 4: Import the extracted part section line 1 and forging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com