Lubricant composite for niobium alloy cutting process technology

A lubricant composition and cutting processing technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems such as easy formation of lubricating oil film, and achieve the effects of improving service life and quality of processed parts, low odor, and good cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

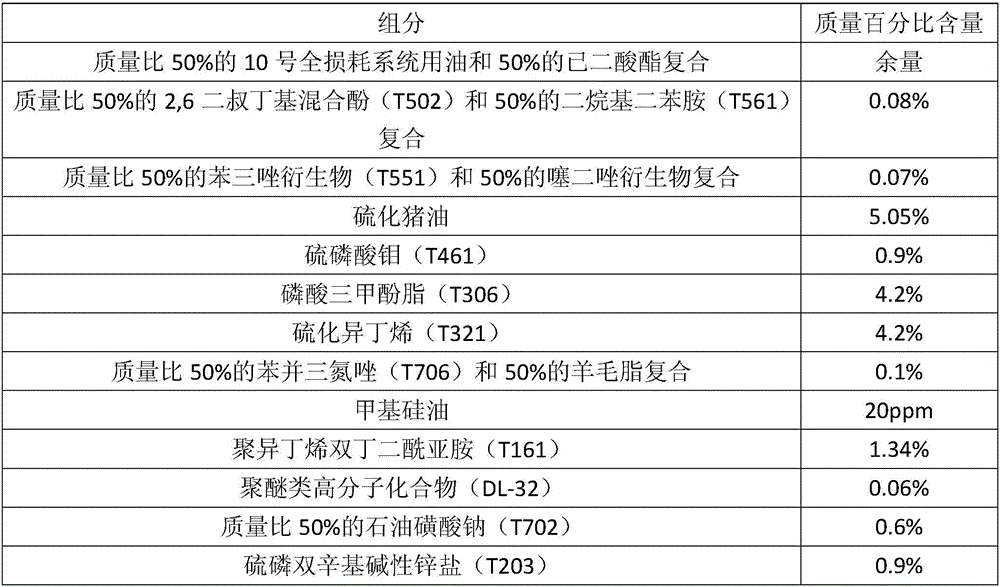

Embodiment 1

[0021] The following components are blended according to the following mass percentages:

[0022]

[0023] The sum of the mass percentages of the above components is 100%.

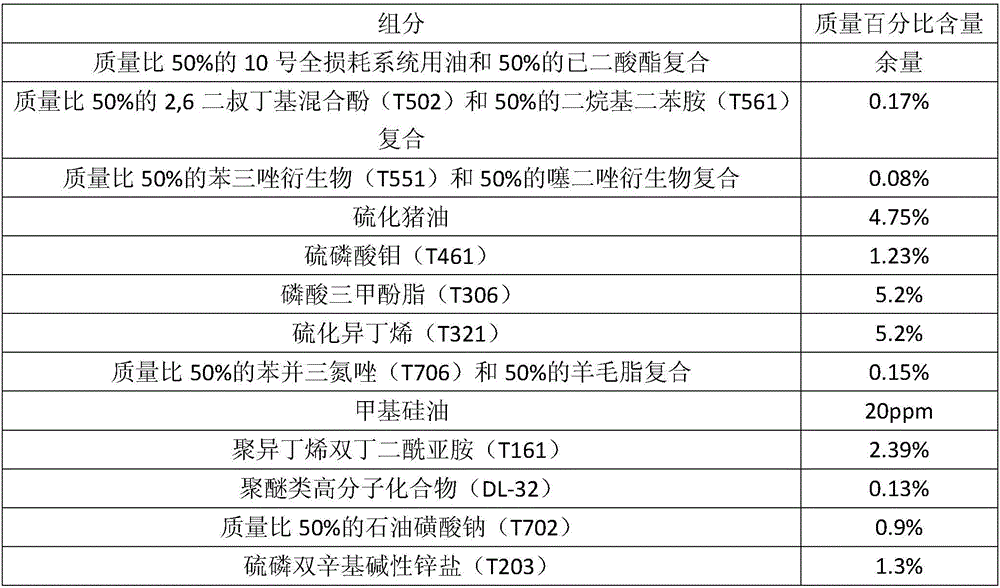

Embodiment 2

[0025] The following components are blended according to the following mass percentages:

[0026]

[0027] The sum of the mass percentages of the above components is 100%.

Embodiment 3

[0029] The following components are blended according to the following mass percentages:

[0030]

[0031] The sum of the mass percentages of the above components is 100%.

[0032] The main technical index of embodiment 3 products:

[0033]

[0034] The main technical index of embodiment 2 products:

[0035]

[0036] The main technical index of embodiment 1 product:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com