Method for preparing hard bean curd based on ultra-high pressure sterilization technology

An ultra-high pressure sterilization and technical technology, applied in the field of food processing, can solve the problems of insufficient aftertaste, unstable quality, and flavor changes, and achieve the effects of avoiding cooking flavor, uniform flavor distribution, and prolonging shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with specific embodiments.

[0021] 1. Prepare raw materials

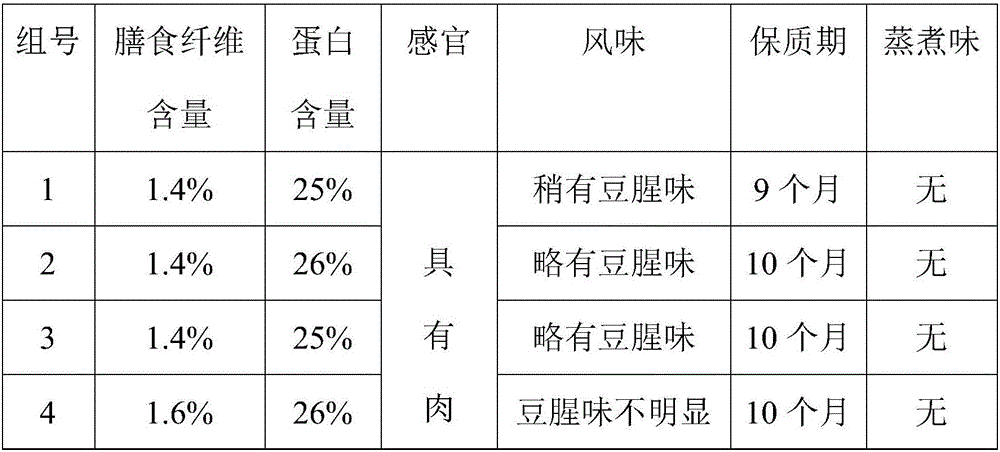

[0022] Table 1 Raw materials and proportioning used for preparing dried tofu

[0023] Group No wet okara Low temperature defatted soybean meal gluten 1 100kg 20kg 40kg 2 100kg 20kg 60kg 3 100kg 20kg 80kg 4 100kg 40kg 40kg 5 100kg 40kg 60kg 6 100kg 40kg 80kg 7 100kg 60kg 40kg 8 100kg 60kg 60kg 9 100kg 60kg 80kg

[0024] 2. Preparation method

[0025] 1. Mixing

[0026] Mix wet bean dregs, low-temperature defatted soybean meal, and gluten, and stir evenly with a noodle mixer to obtain a mixture.

[0027] 2. Squeeze

[0028] The mixture is extruded by a twin-screw extruder to obtain a semi-finished product with uniform structure and properties, which is cut off and dried for later use.

[0029] It is more appropriate to contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com