a constant pressure spring

A technology of constant pressure springs and elastic materials, applied in springs and other directions, can solve problems such as the inability to achieve constant elastic force functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

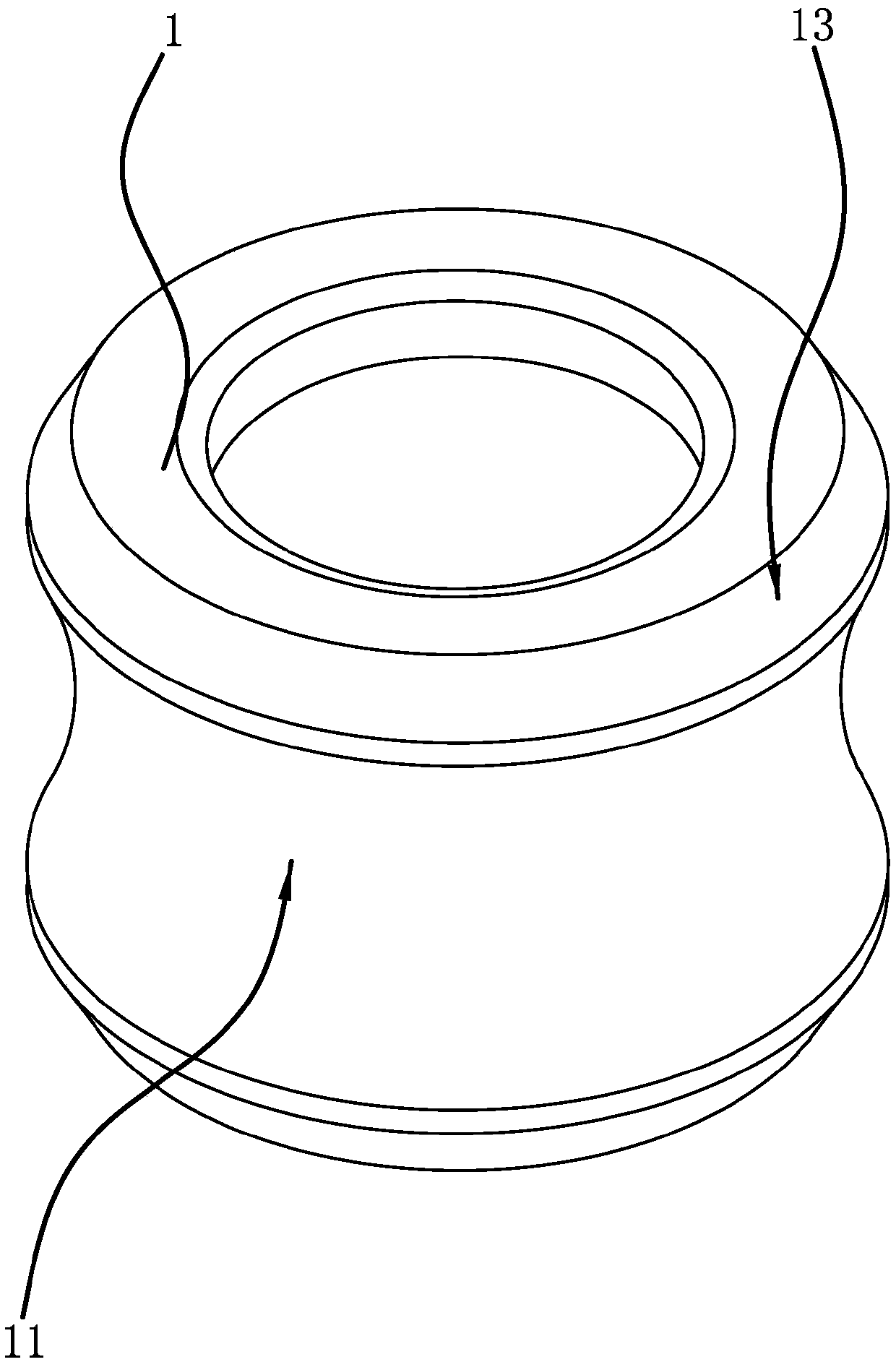

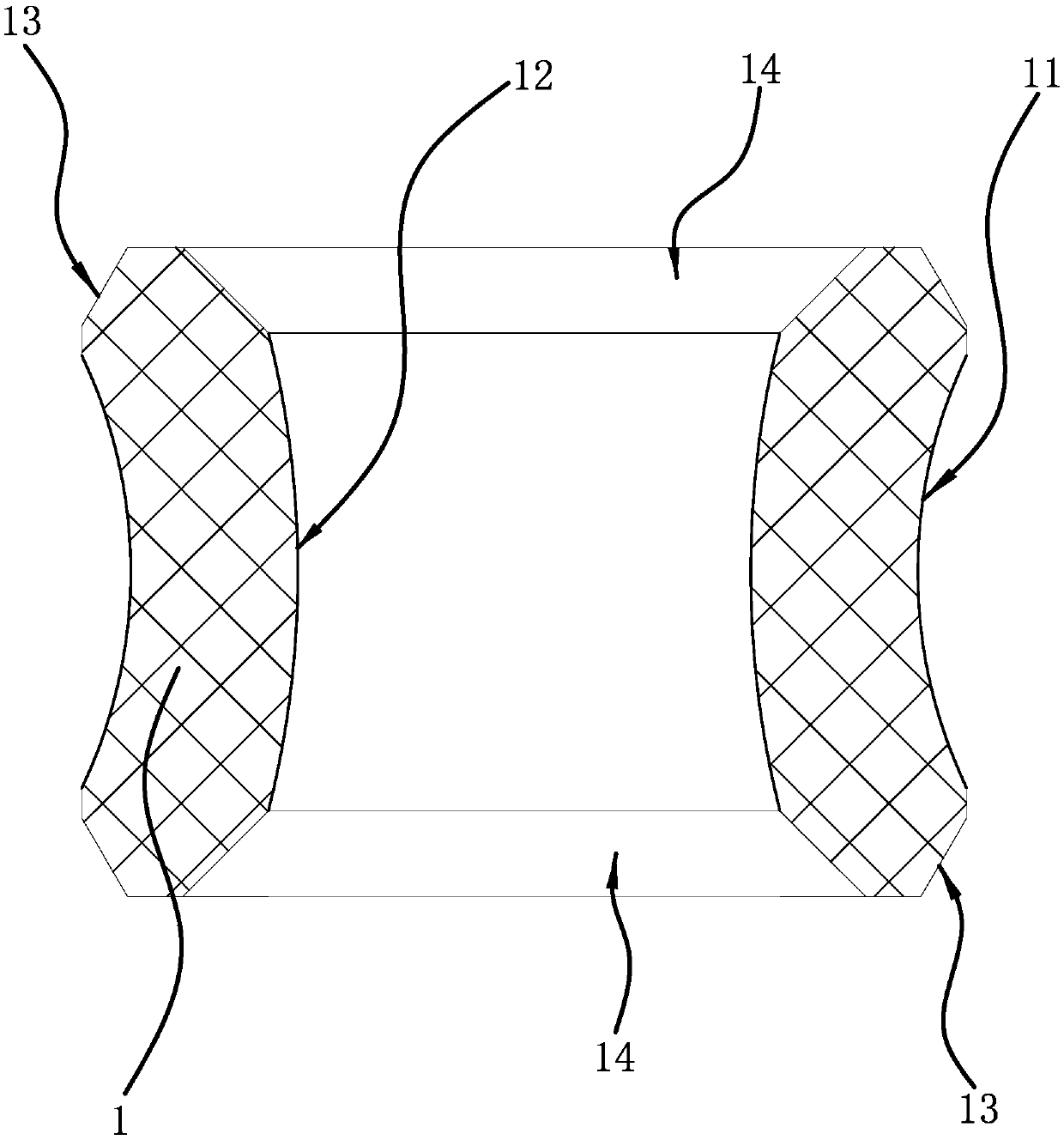

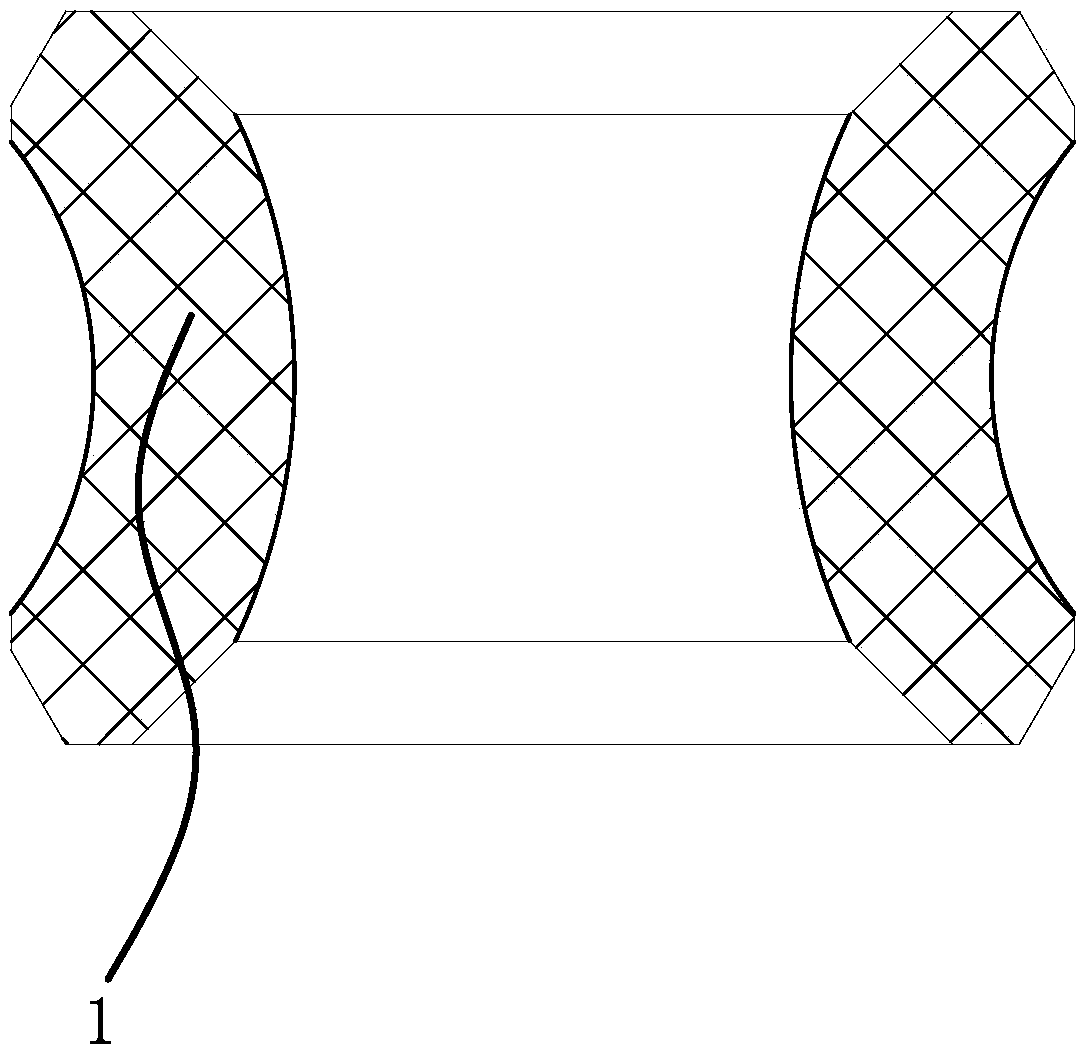

[0026] Such as figure 1 , figure 2 As shown, a constant pressure spring includes a cylindrical body 1. The body 1 is a solid structure and is made of polyurethane material. The outer peripheral surface of the body 1 is a concave surface 11 with an axial middle part inwardly curved inward. , the inner peripheral surface of the main body 1 is a convex surface 12 with an axial middle part that is arc-shaped outwards. In view of the inner peripheral surface of the main body 1 is a convex surface 12, the main body 1 has a center with a small diameter in the middle and large diameters at both ends. holes, and the thickness of the body 1 can be designed according to the hardness of the body 1 and the diameter of the central hol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap