Strip mine steep-wall mining method

A mining method and open-pit mining technology, which is applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of long production and production period, long rock stripping time, and high investment risk, so as to prevent missing ore and reduce stripping. The effect of rock volume and early production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In order to solve the problems in the prior art that the amount of rock stripping in the early stage is huge, the rock stripping time in the early stage is long, and the mining time is late, the embodiment of the present invention provides a steep side mining method in an open-pit mine. The method includes:

[0024] In the area between the ground surface status line and the open-pit end boundary line, N inclined mining zones are divided in turn, which are respectively the first mining zone, the second mining zone, ... the Nth mining zone, wherein, N≥2 and N is an integer, and the 1st mining zone is the mining zone where the working side is the farthest from the open-air end boundary in the N mining belts, and the N mining zone is the mining zone where the working side is the closest to the open-air ending boundary in the N mining belts;

[0025] In the embodiment of the present invention, the number of mining zones can be reasonably designed according to actual mining co...

Embodiment 2

[0038] The embodiment of the present invention is an example of mining an open-pit mine using the mining method described in the first embodiment.

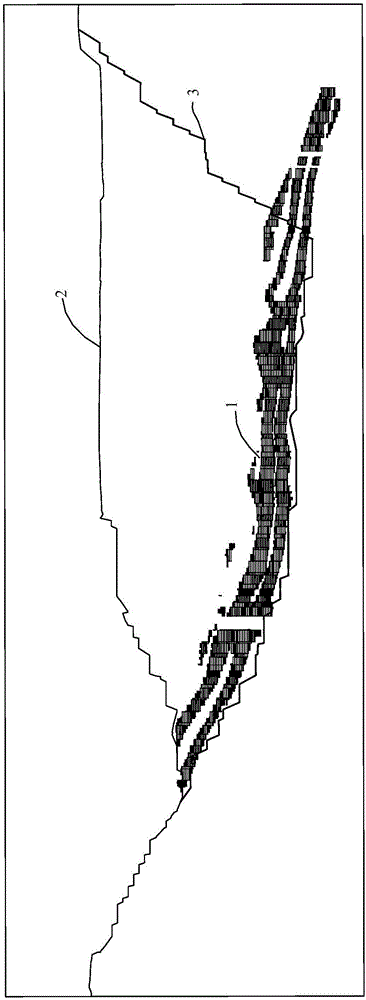

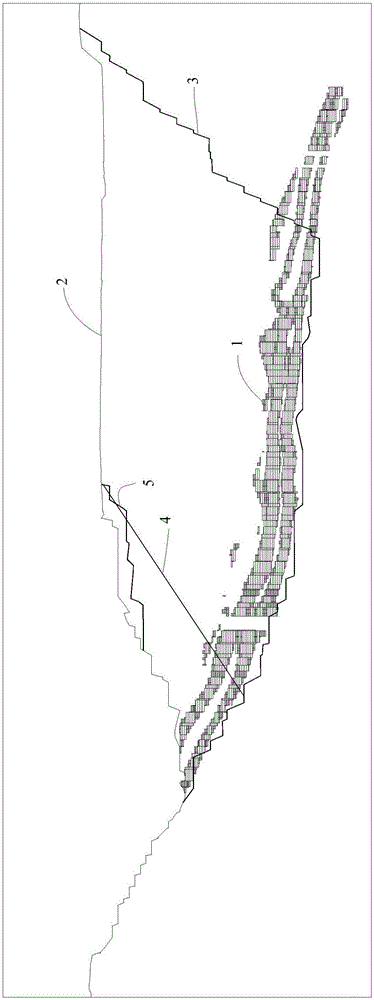

[0039] Such as figure 1 As shown, the open-pit mine is a gently inclined open-pit mine, the occurrence of ore body 1 is relatively deep, and the rock layer on the upper part of ore body 1 is relatively thick. According to the mining conditions of the open-pit mine, four inclined mining zones are designed, 2 is Surface boundary line, 3 is the open-air end boundary line, and four mining zones are divided between the surface boundary line 2 and the open-air end boundary line 3, such as figure 2 As shown, 4 is the first mining zone.

[0040] Rock stripping is carried out from top to bottom to the first mining zone 4 within the bandwidth of the first mining zone 4, figure 2 5 is the state map of open-pit mining in the first year, and 5 is the actual mining boundary line;

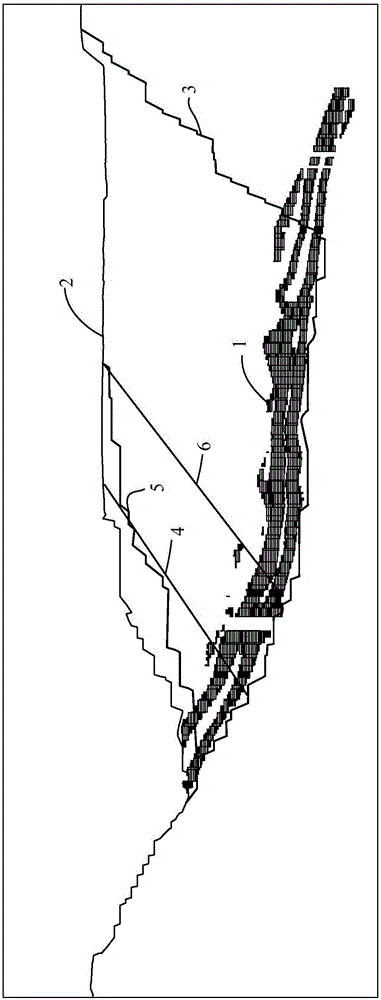

[0041] Such as image 3As shown, it is the state map of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com