A weak electric pulse activation-quenching agglomeration desalination reactor for treating industrial wastewater

A technology for industrial wastewater and reactors, applied in water/sewage treatment, chemical instruments and methods, water/sewage treatment equipment, etc., can solve frequent and complex system operation and maintenance, long electrode self-regeneration time, large equipment footprint, etc. problems, to achieve the effect of being conducive to large-scale promotion and application, eliminating the risk of chemical substances, and occupying a small area of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

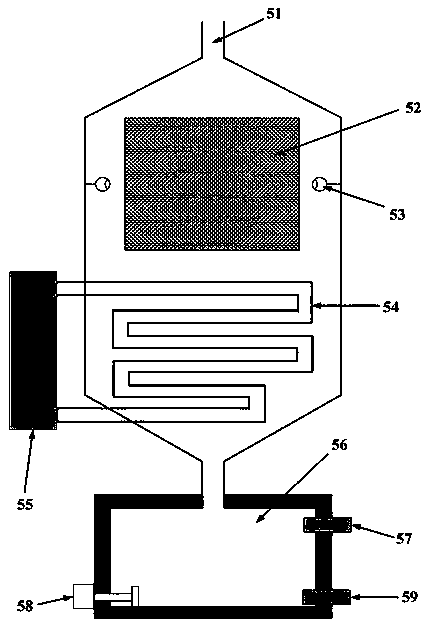

[0029] Such as figure 1 As shown, a weak electric pulse activation-quick cooling reunion desalination reactor for treating industrial wastewater, the weak electric pulse activation-quick cooling reunion desalination reactor 5 is made of hard glass fiber reinforced plastics, and the top of the reactor is provided with a water inlet valve 51, inside the reactor A fan of magnetized nickel metal mesh 52 is fixed in the middle, and a low-voltage underwater electrode 53 is installed on both sides of the magnetized nickel metal mesh 52. A group of cooling pipes 54 are arranged below the magnetized nickel metal mesh 52, and the ends of the cooling pipes 54 are connected to 1 A set of circulating refrigeration unit 55, a set of heat preservation and sedimentation tank 56 is provided at the bottom of the reactor, a drainage valve 57 is provided on the upper right side of the heat preservation sedimentation tank 56, a sludge discharge port 59 is provided at the bottom of the right side, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com