Continuous Bill Sheet Cutting Machine

A cutting machine and bill technology, applied in metal processing, etc., can solve the problems such as rough tearing of bills, joint sheets, cutting difficulties, etc., and achieve the effect of smooth cutting edge, stable work and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

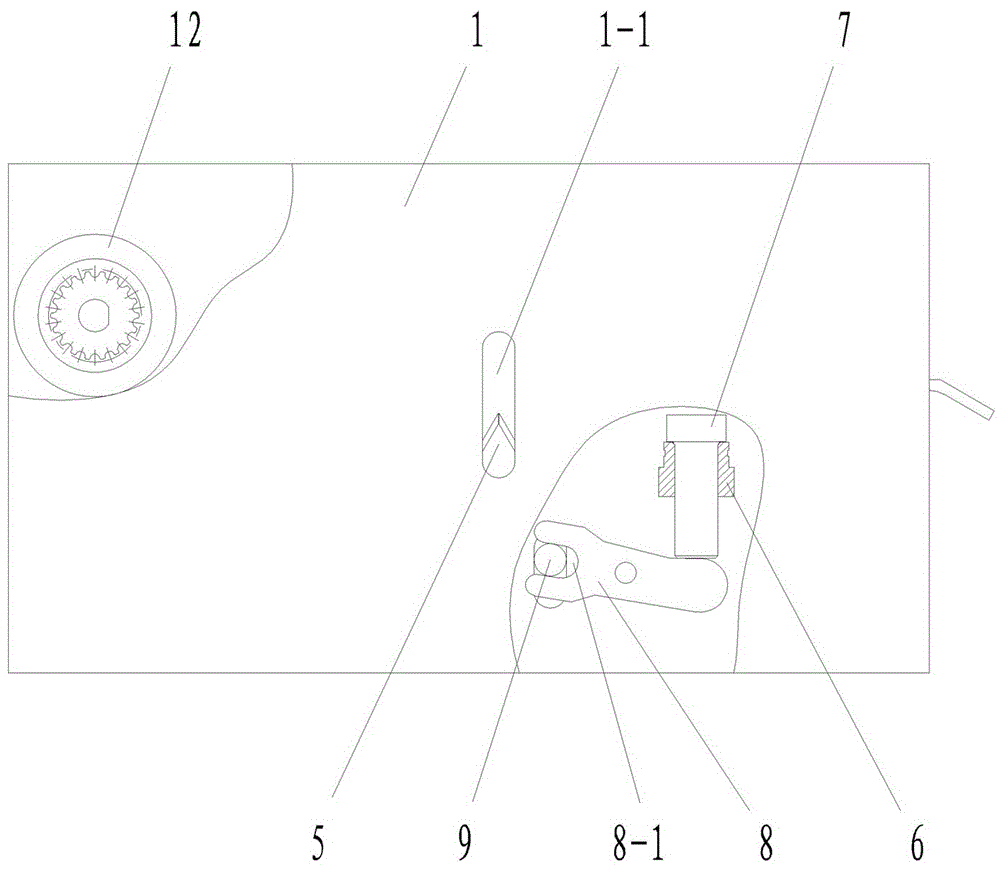

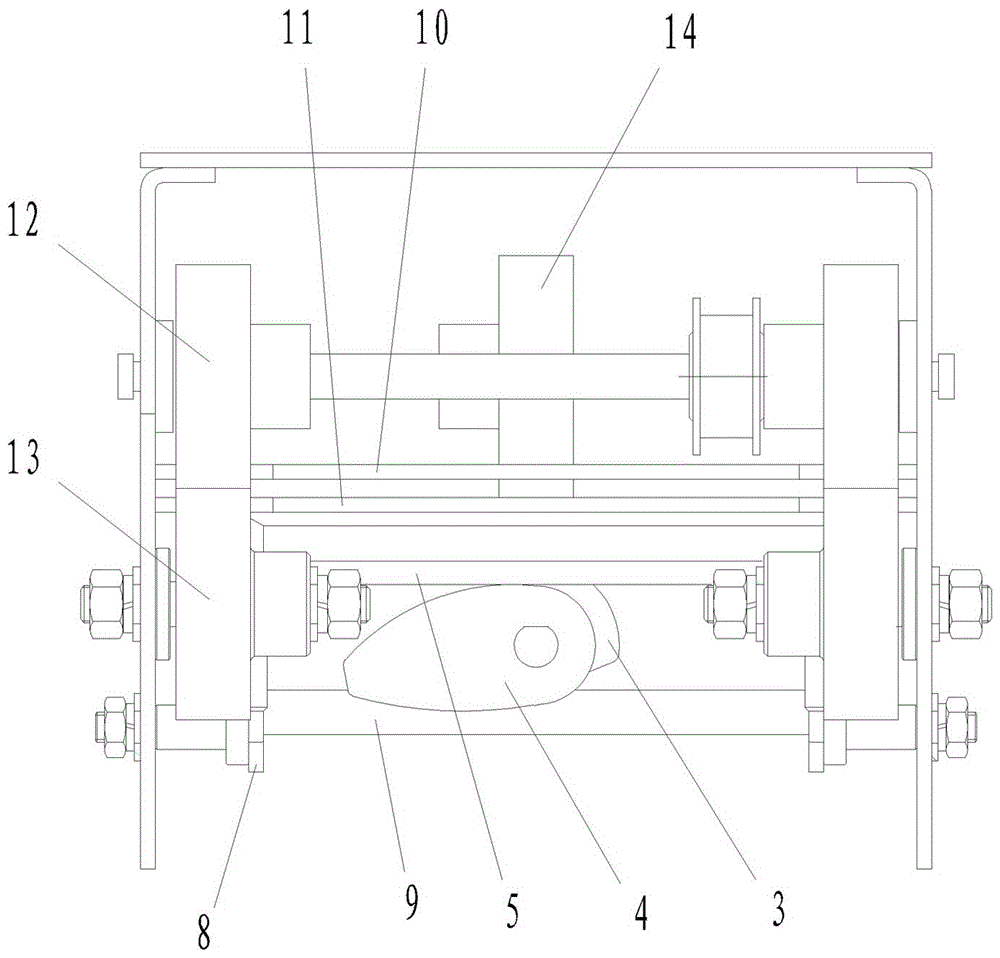

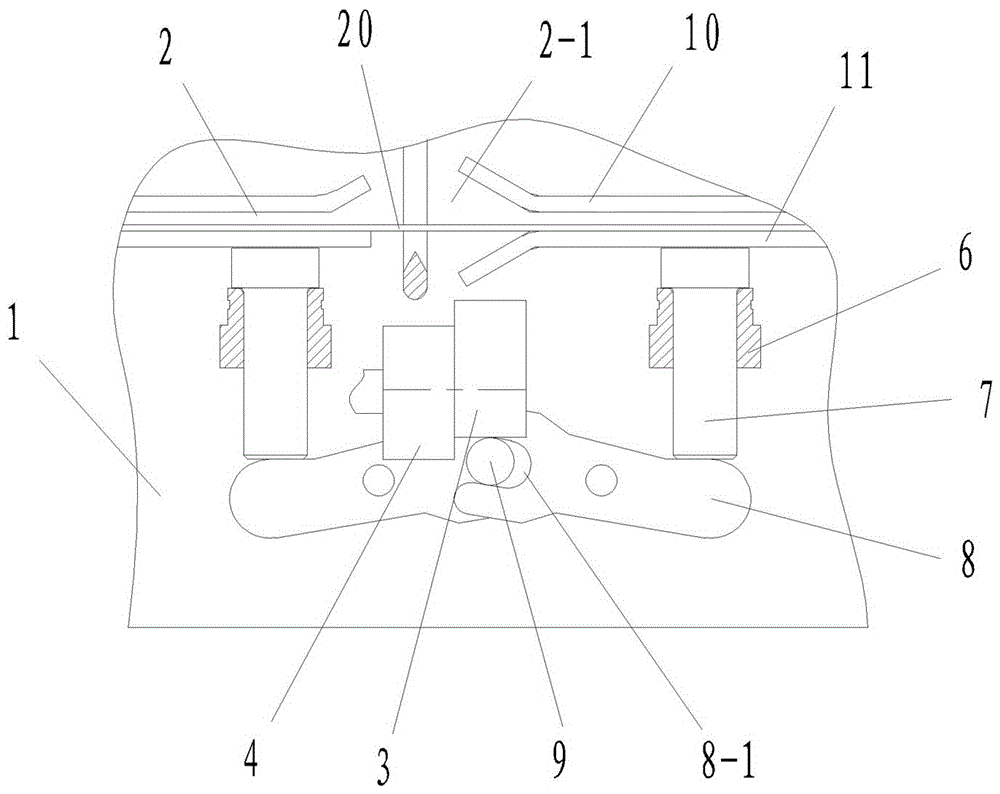

[0028] Example 1: See attached Figure 1-3 , The present invention provides a continuous bill single-sheet cutting machine, which includes a frame 1, a ticket belt conveying channel set on the frame 1, a ticket belt conveying mechanism, a ticket end pressing mechanism, and a bill cutting mechanism. :The ticket end pressing mechanism is provided with two sets and is located below the ticket belt conveying channel 2 and on both sides of the ticket dividing line. The ticket cutting mechanism includes a cutting knife 5 with a cutting edge arranged between the two sets of ticket end pressing mechanisms. And supporting drive mechanism. The slicing blade of the above-mentioned slicing knife 5 cuts one end of the bill with the aid of the slicing drive mechanism and moves to the other end to separate two connected bills.

[0029] See attached Figure 2-8 The two ends of the above-mentioned slicing knife 5 are slidably limited in the vertical slot 1-1 and the vertical slot 1-2 of the fram...

Embodiment 2

[0038] Example 2: See attached Picture 10 The difference from the first embodiment is that the dicing knife 5 is limited in the guide rail on the frame 1, and the dicing drive mechanism is a linear motor. Driven by a linear motor, the scribing knife 5 makes a reciprocating linear motion along the guide rail to achieve the purpose of scribing the bill. In this embodiment, in addition to a linear motor, a belt drive mechanism driven by a motor can also be used. The scoring knife 5 is fixed to the belt of the belt drive mechanism, and the scoring knife 5 is driven by the belt to perform a reciprocating linear motion to separate bills.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com