Antibacterial anticorrosive pipeline material and preparation method thereof

An anti-corrosion and pipeline technology, applied in the field of materials, can solve the problems of shortened pipeline life, uneconomical, and unenvironmental protection, and achieve good anti-corrosion performance, good acid and alkali resistance, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

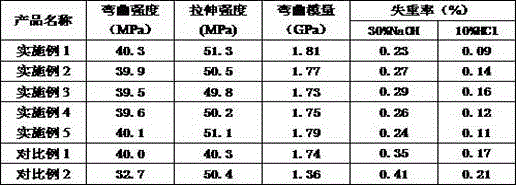

Examples

Embodiment 1

[0017] An antibacterial and anticorrosion pipe material, which is prepared from the following ingredients in parts by weight: 45 parts of polybutene, 45 parts of polypropylene, 17 parts of basalt fiber, 28 parts of titanium dioxide, 9 parts of polyvinyl acetate emulsion, liquid nitrile rubber 0.35 parts, 0.17 parts of calcium lignosulfonate, 1.7 parts of dipentaerythritol diphosphite, 0.4 parts of fatty alcohol polyoxyethylene ether, 0.17 parts of dibenzylidene glycine ethyl ester, 1.7 parts of nano silver, N-bromobutyl 0.17 parts of diimide, 1.7 parts of chlorinated paraffin, 4 parts of nano-alumina, 0.9 parts of silicone oil, 0.4 parts of 1-methylpentanol, and 0.9 parts of guar gum.

[0018] The preparation method of the above-mentioned antibacterial and anticorrosion pipeline material is as follows: (1) mix titanium dioxide, nano-silver, nano-alumina, dipentaerythritol diphosphite and water, and stir slowly at a temperature of 56°C for 1.8 hours; (2) after filtering Dry in ...

Embodiment 2

[0020] An antibacterial and anticorrosion pipe material, which is prepared from the following ingredients in parts by weight: 35 parts of polybutene, 35 parts of polypropylene, 12 parts of basalt fiber, 22 parts of titanium dioxide, 6 parts of polyvinyl acetate emulsion, liquid nitrile rubber 0.25 parts, 0.12 parts of calcium lignosulfonate, 1.3 parts of dipentaerythritol diphosphite, 0.3 parts of fatty alcohol polyoxyethylene ether, 0.12 parts of dibenzylidene glycine ethyl ester, 1.2 parts of nano silver, N-bromobutyl 0.12 parts of diimide, 1.2 parts of chlorinated paraffin, 3 parts of nano-alumina, 0.6 parts of silicone oil, 0.3 parts of 1-methylpentanol, and 0.6 parts of gull gum.

[0021] The preparation method of the above-mentioned antibacterial and anticorrosion pipeline material is as follows: (1) mix titanium dioxide, nano-silver, nano-alumina, dipentaerythritol diphosphite and water, and stir slowly at a temperature of 53°C for 1.3 hours; (2) filter Dry in a vacuum ...

Embodiment 3

[0023] An antibacterial and anticorrosion pipe material, which is prepared from the following ingredients in parts by weight: 30 parts of polybutene, 30 parts of polypropylene, 10 parts of basalt fiber, 20 parts of titanium dioxide, 5 parts of polyvinyl acetate emulsion, liquid nitrile rubber 0.2 part, 0.1 part of calcium lignosulfonate, 1 part of dipentaerythritol diphosphite, 0.2 part of fatty alcohol polyoxyethylene ether, 0.1 part of ethyl dibenzylidene glycinate, 1 part of nano silver, N-bromobutyl 0.1 part of diimide, 1 part of chlorinated paraffin, 2 parts of nano-alumina, 0.5 part of silicone oil, 0.2 part of 1-methylpentanol, and 0.5 part of gull gum.

[0024] The preparation method of the above-mentioned antibacterial and anticorrosion pipeline material is as follows: (1) mix titanium dioxide, nano-silver, nano-alumina, dipentaerythritol diphosphite and water, and stir slowly at a temperature of 50°C for 1 hour; (2) filter Dry in a vacuum drying oven at a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com