Construction method of a pipeline support node structure

A technology of node structure and construction method, applied in the direction of pipeline supports, connecting members, pipes/pipe joints/pipes, etc., can solve the problems of high construction difficulty, complex structure, unable to meet the actual needs of power plant reconstruction projects, etc., to save money and manpower The effect of investment, flexible installation and simplified structure of pipe support nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only for explaining the present invention, and are not intended to limit the scope of the present invention.

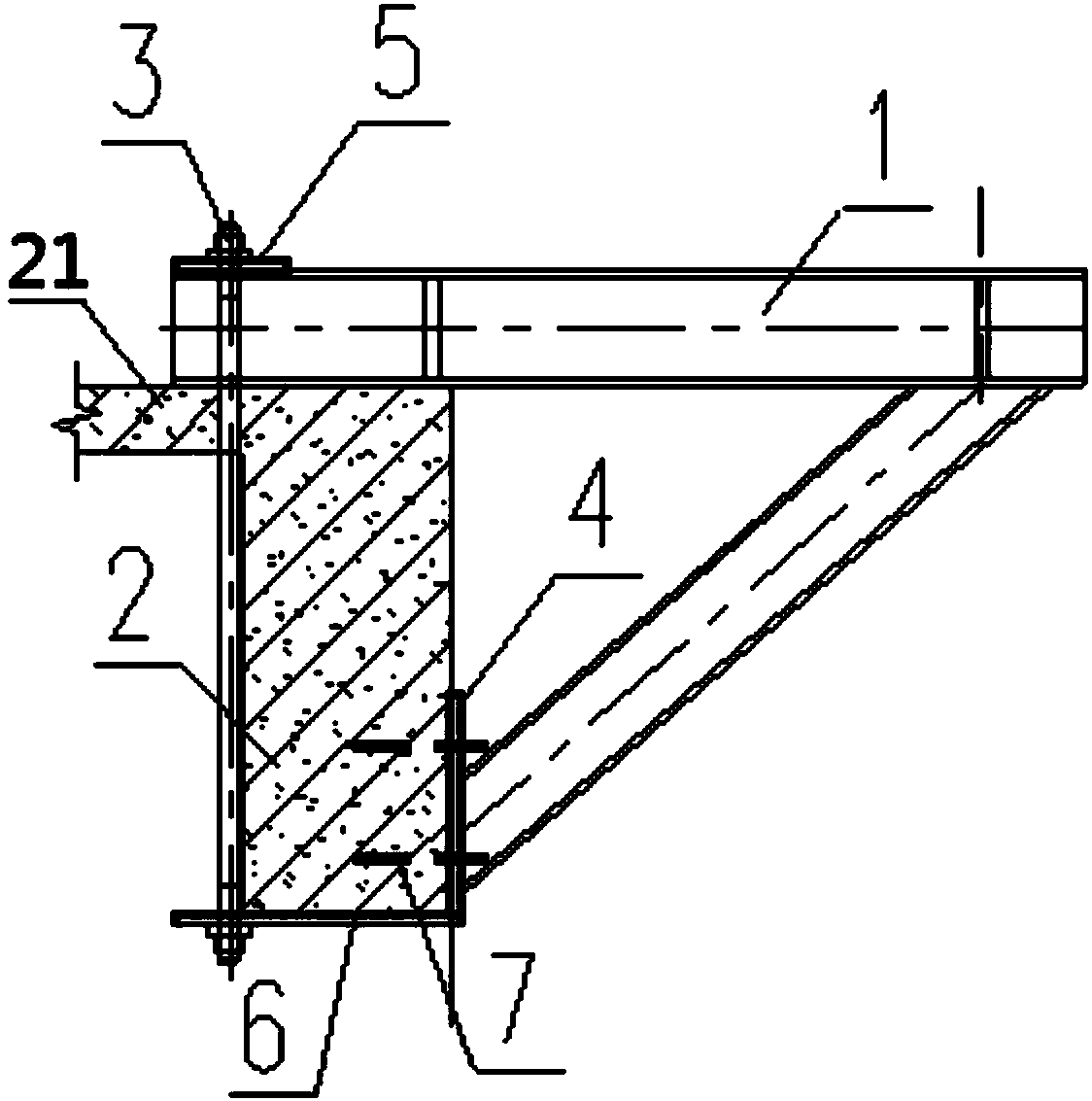

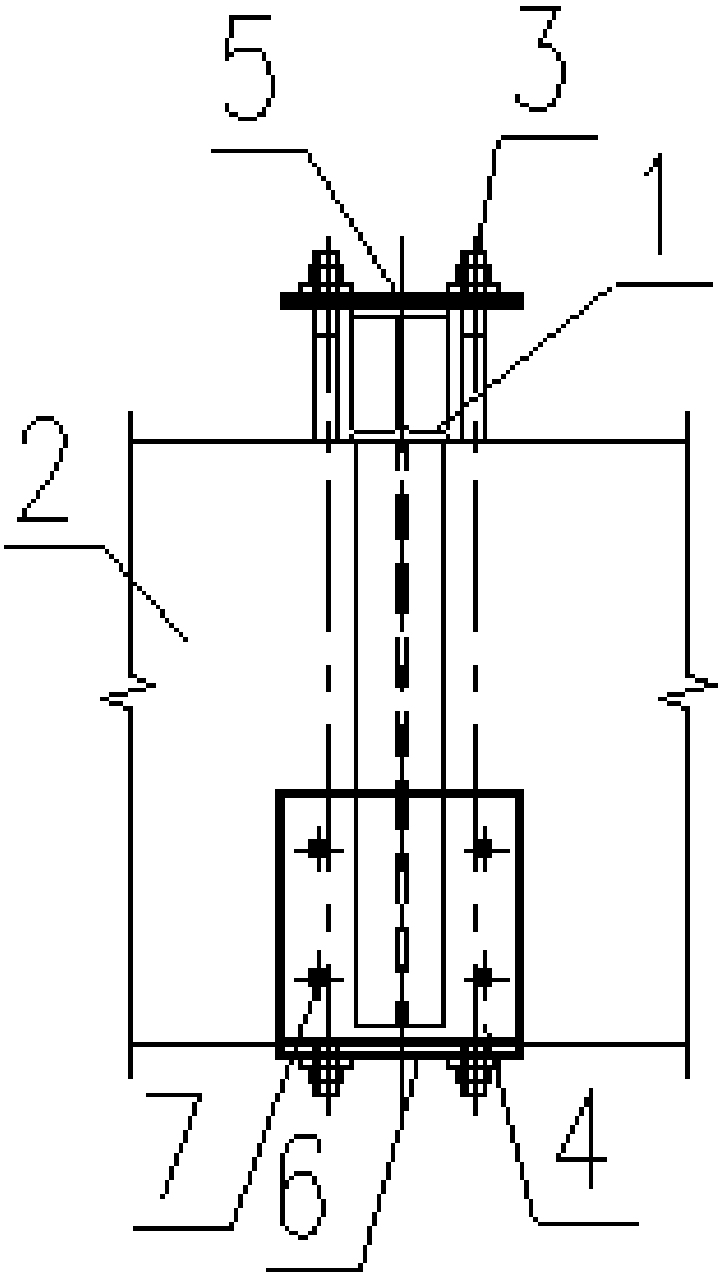

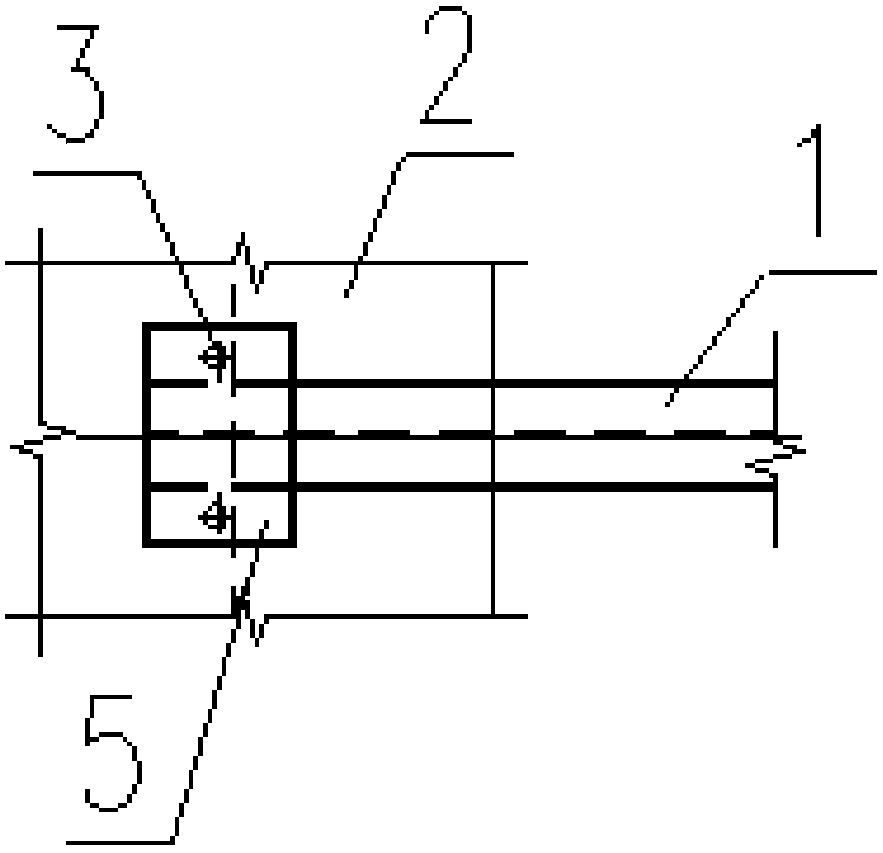

[0032] see Figure 1-3 , a pipeline support node structure, including a reinforced concrete beam 2, a support base and a support 1, the support base includes a connecting bolt 3, the support 1 includes a horizontal bar, and the horizontal bar passes through the upper end surface of the reinforced concrete beam 2 The connecting bolt 3 is connected.

[0033] The pipe support node structure used in the power plant renovation project provided by the present invention provides a scheme for setting the beam side pipe support on the side of the concrete beam and higher than the beam top. Compared with the conventional scheme, by setting the support seat, The fixing effect on the bracket 1 is enhanced, thereby reducing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com